Release time:2022-04-02 Number of views:563

Equipment introduction:

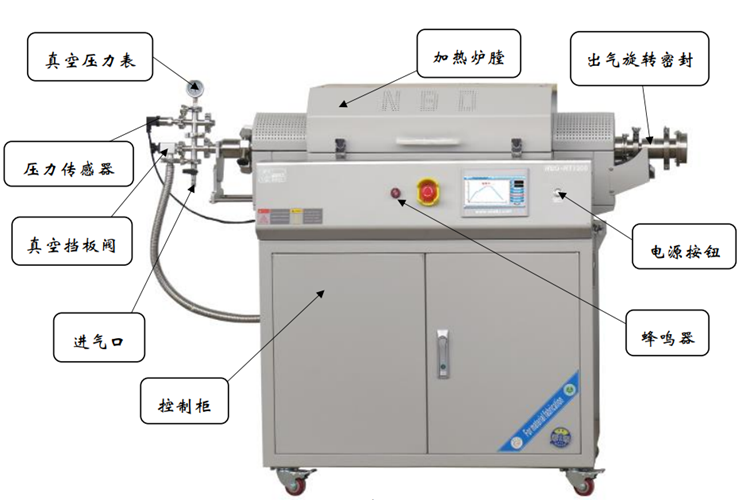

Vacuum atmosphere rotary furnace is a powder heat treatment equipment with high degree of automation, which can be used for lithium battery anode and cathode materials, rare earth materials, chemical catalysts, magnetic materials, powder hydrogen reduction and other aspects of material heat treatment preparation. The equipment can be tilted and continuously rotated to ensure that the material is heated evenly to ensure the sintering effect.

Configuration

|

|

1. The equipment consists of heating system, furnace body lifting system, furnace tube rotation system, vacuum system and gas inlet and outlet system. |

||||||||

|

Model |

NBD-RT1200-120I3TD2ZY |

||||||||

|

Electrical Spec |

three phase 380V 50HZ |

||||||||

|

Tmax |

1200℃ |

||||||||

|

Max working temps. |

1150℃ |

||||||||

|

Heating rate |

10℃/min |

||||||||

|

Heating zone size |

φ150*600mm |

||||||||

|

Furnace tube material and size |

Quartz tube with bulging belly; The two sides are φ60mm, the middle is φ120mm, the total length is 1200mm

|

||||||||

|

Horizontal effective volume of furnace tube |

1L |

||||||||

|

angle of inclination |

30 degrees (discharge) ~2 degrees (feed) |

||||||||

|

Furnace tube rotation speed |

0.1~5 RPM |

||||||||

|

Furnace structure |

The furnace can be opened, and the φ100mm and φ80mm tube diameters can be changed according to the different furnace tubes used, and the rotation function can be realized, the speed is 0-12.6r/min. |

||||||||

|

Control system |

|

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely;

|

|||||||

|

Temp Accuracy |

+/- 1 ℃ |

||||||||

|

Heating element |

|

Mo-doped Fe-Cr-Al alloy |

|||||||

|

Sealing system |

1. High vacuum MHD rotary seal; |

||||||||

|

Pressure measurement and monitoring |

|

1. The mechanical pressure gauge with damping oil can prevent the pressure gauge pointer from being damaged, and the pressure sensor can accurately display the internal force change of the furnace tube in real time; |

|||||||

|

Gas supply system |

|

The two-channel mass flowmeter control system can accurately control the intake volume. |

|||||||

|

Net weight |

180KG |

||||||||

|

Safety function |

1. With overtemperature alarm, broken couple prompt, leakage protection, etc.; |

||||||||

|

选配功能 |

远程监控: 1.实时查看烧结曲线及报警信息; 2.远程操作含启停加热、启停真空系统、修改工艺等。 |

||||||||

|

设备使用注意事项 |

1. 设备炉膛温度≥300℃时,禁止打开炉膛,避免受到伤害; 2. 设备使用时,炉管内压力不得超过0.125MPa(绝对压力),以防止压力过大冲开密封法兰; 3. 设备建议处理微米粉末或颗粒状样品,纳米粉末不建议使用此款产品。 |

||||||||

|

服务支持 |

一年有限保修,提供终身支持(保修范围内不包括易耗部件,例如炉管和密封圈等)。 |

||||||||

相关产品

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|