Release time:2022-03-10 Number of views:1928

|

|

Equipment introduction:

|

||

|

|

|

|

|

|

|

|

|

|

Configuration

|

Equipment features:

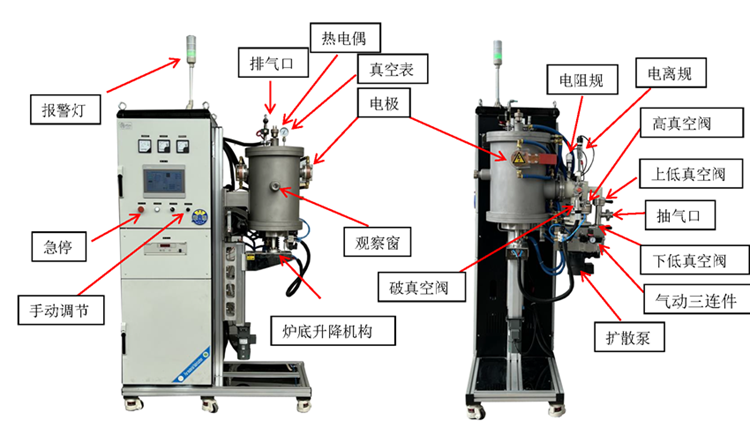

1. Single-chamber vertical structure, mainly composed of furnace body, furnace cover, furnace bottom and lifting mechanism, heating element, vacuum system, temperature field, gas supply system, water cooling system, electric control system, etc.; 2, the furnace body adopts double-layer water-cooled structure, the upper and lower flanges are welded into a cylindrical structure, the inner wall is 304 stainless steel fine polishing to ensure high vacuum, the outer wall is 304 sandblasting treatment, and the middle is cooled by water. The plane of the stainless steel flange is provided with a sealing groove, and the "O" type fluorine rubber ring is vacuum sealed. In order to prevent the "O" ring from aging due to high temperature, water cooling devices are provided at the flange. The side of the furnace body is provided with a monitoring thermocouple, an observation window, an air intake port, two electrode interfaces and a vacuum air outlet connected with the vacuum unit. The monitoring thermocouple is used to monitor the temperature of the metal heat insulation screen on the side to prevent the temperature outside the heat insulation screen from being too high and causing accidents. 3, the furnace cover is also double-layer water-cooled structure, and the upper and lower furnace cover and the central small furnace cover are double-layer water-cooled flat cover structure, the inner wall is 304 stainless steel fine polished to ensure high vacuum, the outer wall is also 304 stainless steel and flange group welded, and the middle is cooled by water. The large furnace bottom and the central small furnace bottom adopt the quick-discharge locking structure, which is convenient for the opening and closing of the small furnace cover. The bolt locking structure is adopted between the large furnace cover and the furnace body, and the "O" jaw rubber seal is adopted to ensure the high vacuum degree. The furnace cover is equipped with tungsten-rhenium thermocouple temperature measuring port, safety valve device, exhaust port and so on. 4, the bottom of the furnace and lifting mechanism: the bottom of the furnace is the same structure as the furnace cover, and the bottom of the small furnace is provided with a feed platform, the lower part of the feed in and out, the lifting system is composed of a linear guide rail device. 5, vacuum acquisition and measurement system:

The vacuum acquisition system is composed of a K-100 diffusion pump and cooling trap, a TRP-36 direct mechanical pump, vacuum pipe, vent valve, manual butterfly valve, vacuum pressure gauge, etc.

|

|||||||||

|

Model |

NBD-B2200-80TIGF |

||||||||

|

Electrical Spec |

AC380V 25KW |

||||||||

|

Tmax |

2200℃ |

||||||||

|

Effective response cavity size |

Φ80*80mm |

||||||||

|

Work area size |

Φ100*210mm |

||||||||

|

Master operating temperature |

2200℃(±0.5℃) | ||||||||

|

heating element |

Tungsten cage, annular heating overall sealing | ||||||||

|

Main control furnace material |

Metal multi-layer heat insulation screen, composed of tungsten sheet, high temperature molybdenum sheet, double stainless steel (304), etc |

||||||||

|

Sealed and water-cooled |

Water-cooled stainless steel sealing flange, water cooling device (to prevent the aging of the "0" ring due to high temperature), the suction hole is connected with the vacuum unit, the observation hole shielding, the electrode extraction device hole, the furnace body hanging device |

||||||||

|

temperature measurer |

Tungsten-rhenium thermocouple |

||||||||

|

Charging line |

It is composed of pipeline, solenoid valve and glass rotor flowmeter 7L/min |

||||||||

|

furnace body

|

Double-layer water sandwich structure is adopted, the inner wall is polished with 304 stainless steel, the outer wall is polished with high-quality stainless steel and the upper and lower flanges are welded into a cylindrical structure, and the flange plane is set up with a sealing groove and the vacuum seal of "0" ring. |

||||||||

|

Small hearth cover

|

The inner wall of stainless steel round plate is equipped with tungsten rod, material tray, positioning column and heat insulation screen positioning column, and the sealing groove is set up to open and close the cylinder in and out of the material |

||||||||

|

Heat shield and cover

|

The all-metal multi-layer heat insulation screen is composed of tungsten sheet, high temperature molybdenum sheet, stainless steel (304), etc. The screen cover and small screen cover use the same material structure, and the bearing platform is composed of tungsten plate and tungsten pillar with a thickness of 8mm |

||||||||

|

Vacuum pump type |

Diffusion pump + direct rotary vane NBD-4C vacuum pump |

||||||||

|

Cold limit vacuum |

6.67×10-3Pa |

||||||||

|

Rate of pressure rise |

≤4Pa/h |

||||||||

|

Uplift structure

|

Double slide rail structure, C7 power distance ball screw, SPY aluminum support hard optical axis linear guide, 57CM23 closed-loop stepper motor, smooth high-speed, high-precision smooth operation, large torque harmonic deceleration feed speed adjustable, material under the push motion mode |

||||||||

|

Refrigerating unit system |

R22, 10-30℃, arbitrarily set within the temperature control range, closed cycle |

||||||||

|

Control mode

|

NBD-101EP embedded operating system English and Chinese interchangeable graphical interface, 10 inch true color touch screen input, intelligent man-machine dialogue mode; The difference between temperature control and sample temperature is controlled, and the system makes nonlinear correction throughout the whole process |

||||||||

|

Sintering process setting

|

15 groups of process curves can be pre-stored, including temperature, sintering end, alarm warning, and generate experimental report export | ||||||||

|

realize function

|

Can be applied to vacuum or atmosphere or state small sintering all kinds of products; Can be reserved sintering, to achieve unattended sintering process curve sintering; Display the information of sintering power and voltage in real time and record the sintering data, and can be exported to achieve paperless recording | ||||||||

|

Remote and secure control |

With remote control, real-time observation of equipment status; Overtemperature alarm, overcurrent protection, break even warning | ||||||||

|

Control system |

|

1. NBD-101EP embedded operating system interchangeable graphical interface, 7-inch true color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; The experimental report is generated independently, and the experimental data is exported unlimited times.

|

|||||||

|

Temp Accuracy |

+/- 1℃ |

||||||||

|

Heating element |

|

|

|||||||

|

Excellent acid and corrosion resistance of graphite heater/tungsten molybdenum heater |

|||||||||

|

Cautions |

1, always pay attention to the temperature of the furnace cover, furnace body, furnace bottom and water-cooled electrode, can not be hot, otherwise to stop heating, check whether the water is smooth. 2, if the vacuum degree is not pumped, it should be checked whether the oil in the diffusion pump is oxidized, and whether the mechanical pump is aging, such as aging should be replaced in time. 3, when filling protective gas, attention should be paid to the value of the vacuum pressure gauge, which can not exceed the positive pressure (generally 2-3 cells below 0 and about -50Pa, the furnace is still negative pressure). It should be noted that the gas has the characteristics of thermal expansion, if close to the positive pressure, you can open the mechanical pump and pre-extraction valve to remove part of the gas. 4, when loading, be sure not to touch the graphite heating body (saw seam), because the heating body is fragile after burning, causing unnecessary losses. 5, usually should pay attention to the furnace, outside the furnace cleaning, vacuum valve maintenance work. 6, after opening the pump, pay attention to check whether each valve is fully opened, and the connected water pipe is not dripping, if any, it should be eliminated in time.

|

||||||||

|

Service |

1 year warranty with lifetime support (warranty does not cover consumable components such as furnace tubes and seals). |

||||||||

Related products

|

|

|

|

|

|

|

|