Release time:2020-06-03 Number of views:6374

High temperature tube furnace, vertical tube furnace, atmosphere CVD system, using corundum furnace tube as heating cavity high purity corundum furnace tube (or corundum products), while making use of its high purity and high temperature quality characteristics, we must follow the inherent characteristics of corundum material (relatively poor thermal shock resistance, not resistant to acute cold and heat), careful operation in the use process. Improper operation will cause the furnace tube or crucible burst (will not be used, please purchase carefully) In order to improve the service life of high purity corundum products, reduce the loss caused by improper use of damage, the following suggestions are put forward for the user's reference:

First, cause of furnace tube or crucible crack analysis:

A. The temperature difference is too large:

1. When using high temperature furnace tube (or corundum products), it is best to control the heating and cooling speed of 5 degrees/minute, the slower the better. Rapid cooling and rapid heating is one of the main reasons for corundum furnace tube breakage. The use temperature under atmospheric pressure is generally not more than 1650℃;

2. Please always keep the tube clean, clean the inner wall of the furnace tube in time after use, do not remain some samples in the tube, in order to avoid chemical reactions, high temperature area should avoid mixing impurities, especially metal debris and non-metallic mineral raw materials containing K2O, Na2O, CaO, SiO2, etc., otherwise easy to form low temperature eutectic and corundum tube damage and cracking;

3. Do not go above 150 degrees during lofting and sampling, and push slowly from edge to center. High temperature sample delivery and sampling is the main cause of corundum tube fracture. It is forbidden to touch high temperature furnace tube with low temperature objects and avoid directly inserting corundum tube into high temperature furnace. When cooling, it should be cooled naturally after the temperature drops to 300 degrees, and the rate of rise and fall is controlled to about 5 degrees Celsius. It can not be cooled by air or cooling water indirectly. Local sudden cooling and sudden heating of high purity corundum furnace tube should be avoided, especially the hot corundum tube should be avoided directly placed on the firebrick or refractory fiber blanket under normal temperature, otherwise it is easy to burst. At the same time, the sintered material with high temperature and large heat storage should not move on the contact wall of the corundum furnace tube. If it needs to move, the temperature gradient should be controlled within 200℃.

4. In the need of atmosphere places, the gas flow should not be too large, to 10~50 bubbles per minute is appropriate, avoid cold gas flow caused by excessive temperature difference in the furnace tube is too large, so that the furnace tube fracture, high temperature, due to gas expansion, the amount of bubbles will increase, do not reduce the intake volume, avoid cooling due to the reduction of intake volume caused by sealed water suction into the furnace tube, resulting in the furnace tube burst;

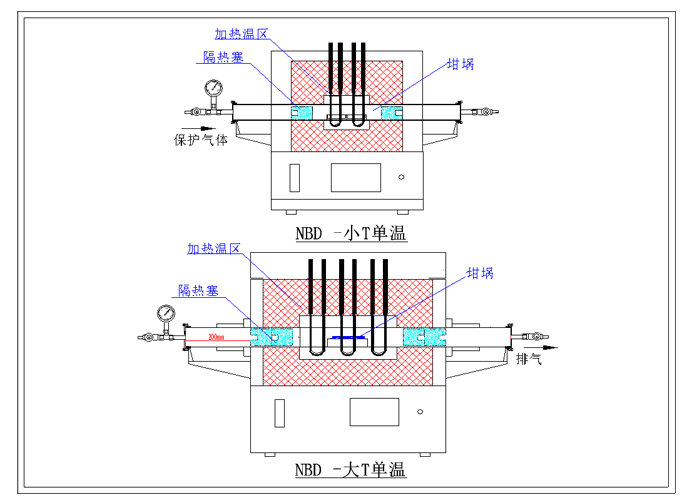

5. In the use of corundum pipe, heat insulation plug (one or two on each side) should be placed in the pipe, the position is between the hot area and the cold area, in order to reduce the temperature gradient caused by cracking.

B. Gravitational deformation:

High temperature use of corundum furnace pipe, it is recommended to add brackets on both sides of the pipe, so as not to cause the pipe because of gravity deformation fracture;

C. Other reasons:

1. The sample burned in the corundum furnace tube, especially the sample burned to about 1300℃, has less water content (water content refers to the adsorption water, crystallized water and water generated in the heating process); For samples with high water content, it is recommended to pre-burn the sample at about 120 degrees, drain the water, and then put it into the corundum furnace tube for sintering reaction;

2. The newly bought furnace pipe should be heated to 1300℃ once at the heating rate of 5℃/min and then used for work, in order to eliminate stress and pollutants;

3. It is recommended that the temperature rise speed should not be too fast. The temperature rise speed is 5-8 ℃/min, and the maximum speed is 10℃/min

(Be sure to set the cooling rate, do not stop the program directly at high temperature)

4. Recommended rising and cooling rate: below 500℃ ≤5℃/min;

500-800℃≤10℃/min;

800-1000℃≤5℃/min;

1000-1400℃≤3℃/min;

1400-1600℃≤2℃/min

5. In order to avoid rupture of high purity corundum furnace tube due to large temperature gradient changes, it is recommended that the tube plug (or reflection screen) in the furnace tube should not overlap with the position of thermal insulation cotton (or thermal insulation support) outside the tube. According to the experience, some tube plug outside will improve the service life of corundum tube accordingly.

6. High purity corundum furnace tubes are brittle and rigid materials. For different use conditions and process methods, the service life of corundum tubes is not the same, which is greatly affected by the use temperature, rising and cooling rate, atmosphere, sintering volatilization and environmental temperature. Hope users can combine their own process characteristics, summed up a set of operating standards most suitable for use conditions.

Ii. Analysis of the causes of tube deformation:

1. If the operating temperature exceeds 1600 degrees for a long time at normal temperature, the furnace tube will be bent and deformed due to gravity;

2. When the temperature for a long time ≧1500℃, the furnace tube is in a gradually softening state and should be used at atmospheric pressure (flow protection atmosphere) as far as possible. The absolute forward pressure inside the furnace tube ≧0.15Mpa will cause the tube to bulge outwards. If the furnace tube is vacuumed and the reverse pressure is ≦0.05Mpa, the furnace tube will be deformed inwardly.