Add Time: 2025-03-12 View:1282

The split vertical ingot melting furnace is a specially designed equipment for melting and casting metal materials, particularly suitable for scenarios that require high-quality alloy production under strict control conditions. When this smelting furnace is equipped with a material stirring system and four automatic rotating crucibles are configured in the lower feeding section, its functionality and flexibility are further enhanced.Application areas:Metallurgical IndustryProduce high-quality al...

| Equipment features:

| ||

Equipment name | Split vertical ingot melting furnace | ||

Equipment model | NBD-PL1100-207TI5LN | ||

power supply | Three phase 380V 50HZ | ||

rated power | 12KW | ||

Furnace temperature control accuracy | ±1℃ | ||

Temperature control sensor | K-type thermocouple with a diameter of 2 * 280mm | ||

Tmax | 800℃ | ||

Recommended heating rate | ≤5℃/min | ||

Size of furnace temperature zone | φ250*430mm | ||

Melting crucible material and size | 310S stainless steel with an inner diameter of φ 207 * 330mm and an effective volume of 5L | ||

Pneumatic high-temperature ball valve diameter for material discharge |

φ20

| ||

Pneumatic valve inlet pipe diameter | Outer diameter φ 8 | ||

Pneumatic valve working pressure | 0.5-1MPa | ||

Material mixing rotation speed | 200-500r/min | ||

Number of mixing rod blades | 3个 | ||

Mixing rod lifting stroke | 100mm | ||

Quantity of feeding crucibles | 4 (automatic rotating workstations) | ||

Horizontal push-pull travel | 500mm | ||

Furnace body size | Length 1690 * Height 1770 * Depth 700mm | ||

Furnace weight | Approximately 440KG (including control cabinet) | ||

| control system

|

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; 2. Pre order sintering is available to achieve unmanned sintering process curve sintering; 3. Real time display of sintering power, voltage and other information, recording of sintering data, and the ability to export for paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is nonlinearly corrected throughout the sintering process.

| |

Equipment Details |   | Four automatic rotating crucibles can achieve continuous operation, with each crucible completing the processes of feeding, melting, and casting in sequence, significantly improving production efficiency. | |

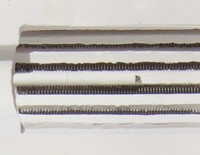

heating element |  | HRE alloy resistance wire | |