-

Vacuum and pressure unit automatic converter (practical free tool)Vacuum and pressure measuring unit converterMore

Vacuum and pressure unit automatic converter (practical free tool)Vacuum and pressure measuring unit converterMore -

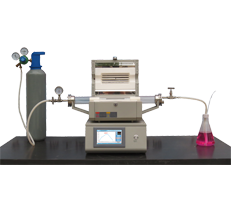

Precautions for the use of mini tube furnace1. After the sample is placed, the two heat insulation plugs should be placed in the correct position. Select a small pressure reducer and connect them as shown in the figure below; 2. Adjust the pressure regulator to the relative pressure ≦0.05Mpa. Open the intake valve and observe the absolute pressure gauge at the intake end. Adjust the flow, observe bubbles, and protect the atmosphere normally.More

Precautions for the use of mini tube furnace1. After the sample is placed, the two heat insulation plugs should be placed in the correct position. Select a small pressure reducer and connect them as shown in the figure below; 2. Adjust the pressure regulator to the relative pressure ≦0.05Mpa. Open the intake valve and observe the absolute pressure gauge at the intake end. Adjust the flow, observe bubbles, and protect the atmosphere normally.More -

Cause analysis of chamber crack in high temperature furnaceWhen cracks occur after ≧5mm, the shrinkage of fiber in non-refractory layer is generally caused by the erosion of volatiles of sintered materials (strong acid and alkali, or lead vapor and vanadium pentaoxide). In actual use cases, some components added in zirconia products of sintered materials and volatiles of dyeing agent of customers are easy to cause cracking of fiber products when caking ... Enter into detailMore

Cause analysis of chamber crack in high temperature furnaceWhen cracks occur after ≧5mm, the shrinkage of fiber in non-refractory layer is generally caused by the erosion of volatiles of sintered materials (strong acid and alkali, or lead vapor and vanadium pentaoxide). In actual use cases, some components added in zirconia products of sintered materials and volatiles of dyeing agent of customers are easy to cause cracking of fiber products when caking ... Enter into detailMore -

Analysis of corundum tube cracking at high temperatureHigh purity corundum furnace tube (or corundum products), while making use of its high purity and high temperature quality characteristics, we must follow the inherent characteristics of corundum material (thermal shock resistance is relatively poor, not cold and hot resistance), careful operation in the use process, improper operation will cause the furnace tube or crucible burst (will not be used, please purchase carefully) in order to improve the service life of high purity corundum products, To reduce the loss caused by damage caused by improper use, the following suggestions are put forward for users' reference: ... Enter into detailMore

Analysis of corundum tube cracking at high temperatureHigh purity corundum furnace tube (or corundum products), while making use of its high purity and high temperature quality characteristics, we must follow the inherent characteristics of corundum material (thermal shock resistance is relatively poor, not cold and hot resistance), careful operation in the use process, improper operation will cause the furnace tube or crucible burst (will not be used, please purchase carefully) in order to improve the service life of high purity corundum products, To reduce the loss caused by damage caused by improper use, the following suggestions are put forward for users' reference: ... Enter into detailMore -

Melt-blown cloth nozzle (plate) mold disjunction cleaning and installation precautionsSetting of cleaning and sintering curve of spinneret: A Vacuum sintering: 1. The vacuum degree of the cleaning furnace should reach 100 ~200Pa during sintering, and the temperature should rise from room temperature to 350℃ in 60 minutes. The vacuum will start when the temperature reaches 100℃; ... Enter into detail 2. Keep warm at 350℃ for 1 hour. 3. Raise the temperature from 350℃ to 450℃ for another 30min. 4. Keep the temperature at 450℃ for 2 hours. 5. When the temperature in the furnace is less than 100℃, open the intake valve at the temperature and let the furnace.More

Melt-blown cloth nozzle (plate) mold disjunction cleaning and installation precautionsSetting of cleaning and sintering curve of spinneret: A Vacuum sintering: 1. The vacuum degree of the cleaning furnace should reach 100 ~200Pa during sintering, and the temperature should rise from room temperature to 350℃ in 60 minutes. The vacuum will start when the temperature reaches 100℃; ... Enter into detail 2. Keep warm at 350℃ for 1 hour. 3. Raise the temperature from 350℃ to 450℃ for another 30min. 4. Keep the temperature at 450℃ for 2 hours. 5. When the temperature in the furnace is less than 100℃, open the intake valve at the temperature and let the furnace.More -

After-sales serviceClick Contact after-sales engineers Tel:86+0371-63202905More

After-sales serviceClick Contact after-sales engineers Tel:86+0371-63202905More

Sale Service: 0371-6320 2801

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China

copyright © 2024 Henan NOBODY Material Technology Co., Ltd

Contact Us