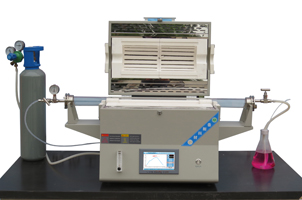

1200°C Vacuum Atmosphere Chamber Furnace(27L)

Release time: 2024-07-08 11:59:12 Number of views: 390

Equipment Introduction:

| Equipment features: 1, high temperature sintering. 2、Stable and reliable control, easy to operate, perfect safety protection measures. 3、Advanced PID self-learning fuzzy control, high precision temperature control, keep at ±1℃. 4、Furnace lining is made of high-purity alumina lightweight fibre material, with better heat preservation effect, energy saving and consumption reduction. 5、With the function of Internet of Things (WIFI), the equipment can be monitored and operated remotely through mobile phones and computers. 6, data storage function, can save the important parameters of sintering, up to 30 days long (8 hours a day boot). 7. Recipe function, can pre-store more than 20 recipes. 8, networking function, through the RJ45 interface, the use of TCP / IP protocol, you can make the system connected to the host computer (host computer need to install the appropriate software). | |||||||

Equipment name | Vacuum Atmosphere Chamber Furnaces | |||||||

Tmax | 1150℃ | |||||||

Specification | VA1200-30BTID2F | |||||||

Power supply | three-phase (physics)380V 50HZ | |||||||

rating | 6KW | |||||||

| Sensor type | Type K thermocouple | |||||||

| temperature rise | 1℃/H-20℃/Min | |||||||

| Furnace size | 300*300*300mm | |||||||

Furnace size | L1100*H1550*D890mm | |||||||

weights | 约280KG | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; 2. Pre order sintering is available to achieve unmanned sintering process curve sintering; 3. Real time display of sintering power, voltage and other information, recording of sintering data, and the ability to export for paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is nonlinearly corrected throughout the sintering process. | ||||||

Temperature Accuracy | ±1℃ | |||||||

heating element |

| Mo-doped Fe-Cr-Al alloys | ||||||

Weakly corrosive gas preheater (Optional) |  | The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃. | ||||||

Precautions for the use of equipment | 1. When the temperature of the furnace chamber of the equipment is ≥300℃, it is forbidden to open the furnace chamber to avoid being hurt; 2. The slight crack produced by the continuous use of the furnace chamber is a normal phenomenon, does not affect the normal use of the equipment. | |||||||

Service Support | One year limited warranty with lifetime support (Warranty does not cover consumable parts such as handling tubes and o-rings, please order replacements at Related Products below). | |||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

| Equipment features: | |||||||

Equipment name | Vacuum Atmosphere Chamber Furnaces | |||||||

Tmax | 1150℃ | |||||||

Specification | VA1200-30BTID2F | |||||||

Power supply | three-phase (physics)380V 50HZ | |||||||

rating | 6KW | |||||||

| Sensor type | Type K thermocouple | |||||||

| temperature rise | 1℃/H-20℃/Min | |||||||

| Furnace size | 300*300*300mm | |||||||

Furnace size | L1100*H1550*D890mm | |||||||

weights | 约280KG | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; | ||||||

Temperature Accuracy | ±1℃ | |||||||

heating element |

| Mo-doped Fe-Cr-Al alloys | ||||||

Precautions for the use of equipment | 1. When the temperature of the furnace chamber of the equipment is ≥300℃, it is forbidden to open the furnace chamber to avoid being hurt; 2. The slight crack produced by the continuous use of the furnace chamber is a normal phenomenon, does not affect the normal use of the equipment. | |||||||

Service Support | One year limited warranty with lifetime support (Warranty does not cover consumable parts such as handling tubes and o-rings, please order replacements at Related Products below). | |||||||

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,诺巴迪公司不定期完善和修改网站任何信息,恕不另行通知。

推荐产品

High temperature, high pressure automatic feeding tube furnace

High pressure and high vacuum rotary pendulum sintering furnace

Multichannel gas automatic controller

glass tempering furnace

Box type crystallizing furnace

Cooling circulator

Single temperature zone tube furnace 1200℃

Three temperature zone 1700 ℃ tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China