High Flux Intelligent Chamber Furnace

Release time: 2024-07-05 15:41:22 Number of views: 300

Equipment Overview:

This equipment a 1500 ℃ four-channel high-throughput chamber furnace, can be used for heat treatment of multiple samples using high-throughput methods, each heating module is controlled by an independent temperature control system, and can be put 4 samples at the same time to process samples at different temperatures.

It is a special equipment developed for colleges and universities, scientific research institutes and industrial and mining enterprises for sintering ﹑ chemical vapour deposition of ceramics, metallurgy, electronics, glass, chemical industry, machinery, refractory materials, new materials development, special materials, building materials, metal, non-metal and other compound materials, which adopts PLC control, touch screen operation, simple and convenient.

Configuration details

| Equipment features 1、Automatic material inlet and outlet system equipped with RF-conducting level switch and stainless steel push material winch, which can realise efficient material inlet and outlet and monitor the material level at any time. | |||

Equipment name | High flux chamber furnace | |||

Specification | NBD-M1500-MGI-4 | |||

Power supply | three-phase (physics)380V/50HZ | |||

rating | 10KW | |||

| Temperature control accuracy | ±1℃ | |||

Temperature measuring element type | Thermocouple type S 220mm | |||

highest temperature | 1450℃ | |||

Recommended temperature rise rate | 5℃/min | |||

Heating temperature zone size | 120*120*120mm | |||

Furnace size | L850mm (without cantilever box) x H1580mm x D600mm | |||

weights | ≈280KG | |||

操作系统 |  2, can be booked sintering, unattended sintering process curve sintering; 3、Real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless records; 4, with remote control, real-time observation of the state of the equipment; 5, temperature correction: the difference between the main control temperature and the sample temperature, sintering throughout the non-linear correction. | |||

Furnace chamber detail |  | |||

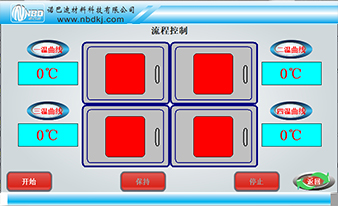

Process & Machine Control Interface |

|

| ||

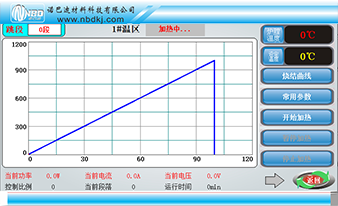

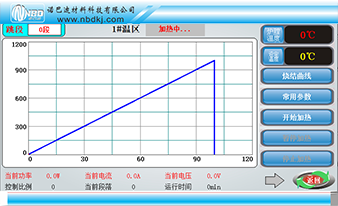

| Process & Recipe Library Interface |  |  | ||

Service Support | One year limited warranty with lifetime support; | |||

Disclaimer: The content of this site product introduction (including product images, product descriptions, technical parameters, etc.), is for reference only. May be due to the update is not timely, perhaps leading to the content of the said and the actual situation there are certain differences, please contact our customer service staff to confirm. The information provided on this site does not constitute any offer or commitment, Nobadi company from time to time to improve and modify any information on the site, without notice.

Related products

| |||

Configuration details

| Equipment features 1、Automatic material inlet and outlet system equipped with RF-conducting level switch and stainless steel push material winch, which can realise efficient material inlet and outlet and monitor the material level at any time. | |||

Equipment name | High flux chamber furnace | |||

Specification | NBD-M1500-MGI-4 | |||

Power supply | three-phase (physics)380V/50HZ | |||

rating | 10KW | |||

| Temperature control accuracy | ±1℃ | |||

Temperature measuring element type | Thermocouple type S 220mm | |||

highest temperature | 1450℃ | |||

Recommended temperature rise rate | 5℃/min | |||

Heating temperature zone size | 120*120*120mm | |||

Furnace size | L850mm (without cantilever box) x H1580mm x D600mm | |||

weights | ≈280KG | |||

operating system |  2, can be booked sintering, unattended sintering process curve sintering; 3、Real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless records; 4, with remote control, real-time observation of the state of the equipment; 5, temperature correction: the difference between the main control temperature and the sample temperature, sintering throughout the non-linear correction. | |||

Furnace chamber detail |  | |||

Process & Machine Control Interface |

|

| ||

| Process & Recipe Library Interface |  |  | ||

Service Support | One year limited warranty with lifetime support; | |||

Disclaimer: The content of this site product introduction (including product images, product descriptions, technical parameters, etc.), is for reference only. May be due to the update is not timely, perhaps leading to the content of the said and the actual situation there are certain differences, please contact our customer service staff to confirm. The information provided on this site does not constitute any offer or commitment, Nobadi company from time to time to improve and modify any information on the site, without notice.

Related products

推荐产品

High vacuum tungsten sintering furnace (2200℃)

Vertical homogenizing melting furnace

High temperature blast drying oven

NOBODY tube furnace, box furnace type naming rules

NBD-103(A) Vacuum system

Vertical quenching furnace

0.45L melting furnace 1200℃

PECVD plasma chemical vapor deposition system

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China