Open type high flux four-channel tube furnace

Release time: 2024-06-28 17:13:22 Number of views: 530

Equipment Introduction:

With its high efficiency, flexibility and precision, this equipment has become an indispensable high-performance equipment for scientific research laboratories and small-scale production, promoting the development of materials science and related technologies.

| Equipment features: 1. four-channel design: the equipment is designed with four independent heating channels, which can be used for multiple experiments or sample processing at the same time, greatly improving the experimental efficiency and production flexibility, suitable for batch processing or comparative research. | |||||||

Equipment name | Open type high flux four-channel tube furnace | |||||||

Specification | NBD-O1200-50TI-80-4 | |||||||

Tmax | 1200℃ | |||||||

| Specification | 1150℃ | |||||||

Power supply | Three-phase 380V 50HZ | |||||||

rating | 5KW | |||||||

Number of temperature zones | four-temperature and four-control | |||||||

temperature rise | 1℃/H-20℃/Min | |||||||

| Sensor type | Type S thermocouple | |||||||

| Temperature zone size | φ80*200mm | |||||||

| Furnace size | L1180*H1650*D610mm | |||||||

control system |

| 1, sintering process curve setting: dynamic display setting curve, equipment sintering can be pre-stored multiple process curves, each process curve can be freely set; | ||||||

Temperature Accuracy | ±1℃ | |||||||

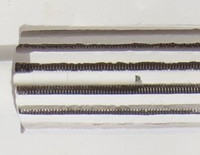

heating element |

| Mo-doped Fe-Cr-Al alloys | ||||||

Pressure measurement and monitoring |

| Adopting mechanical pressure gauge, the gauge shell is gas-tight structure, which can effectively protect the internal parts from environmental influences and debris intrusion, and at the same time has strong corrosion resistance and high temperature resistance. | ||||||

air supply system |

| A float flow meter is used to control the gas flow rate, which is integrated with the equipment and has been tested for leakage before leaving the factory. | ||||||

net weight | ≈180KG | |||||||

Precautions for the use of equipment | 1. When the equipment is used, the absolute pressure gauge reading should not be greater than 0.15MPa to prevent damage to the equipment caused by excessive pressure; | |||||||

Service Support | One year limited warranty, providing lifetime support (the warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below) | |||||||

Disclaimer: The content of this site product introduction (including product images, product descriptions, technical parameters, etc.), is for reference only. May be due to the update is not timely, perhaps leading to the content of the said and the actual situation there are certain differences, please contact our customer service staff to confirm. The information provided on this site does not constitute any offer or commitment, Nobadi company from time to time to improve and modify any information on the site, without notice.

Related products

推荐产品

CVDO1200-XTIG3Z

vacuum braze furnace

Full bridge crystallizing furnace

Insulation mold pressure test system

Well type vacuum atmosphere furnace

Large denture waxing furnace

High temperature vacuum induction furnace

3 station glove box

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China