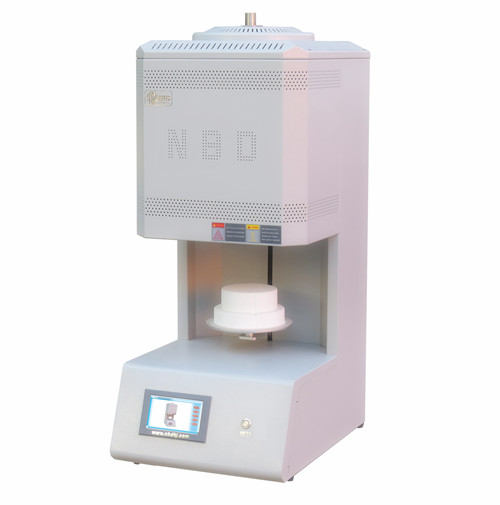

Anti-corrosion mini chamber furnace

Release time: 2024-06-24 09:54:47 Number of views: 278

This anticorrosive mini chamber furnace in the original structure based on the use of fully closed embedded heating element alumina fibre chamber, and closed armoured thermocouples, can avoid the heating element of high temperature precipitates on the experimental results of the impact of the heating element at the same time can effectively improve the service life of the heating element.

Scientific and reasonable pull-down door structure, material removal, can be placed directly on the door to avoid burns on the workbench. It has an exquisite appearance and compact size, is widely used in universities, research institutes laboratory, directly in the large excessive warehouse into the glove box, three sides of the uniform distribution of heating, effectively enhancing the temperature field uniformity in the furnace chamber.

Translated with DeepL.com (free version)

Configuration details

| Equipment features: | ||

Product Model | NBD-ML1200-10CI(Anti-corrosion type) | ||

Electrical Specifications | AC220V 1KW | ||

Reachable temperature | 1200℃(<1 hour) | ||

continuous temperature | 1100℃(progression) | ||

Reachable heating rate | ≤20℃/minutes | ||

Furnace size | 100*100*100mm | ||

control system |

| 1. Fuzzy PID temperature control, high brightness digital tube display; | |

Temperature control accuracy | +/- 1℃ | ||

Heating chamber |

| Fully enclosed alumina fibre chamber with embedded heating elements and enclosed armoured thermocouples | |

net weight | ≈10KG | ||

Precautions for the use of equipment | 1. When the temperature of the furnace chamber of the equipment is ≥300℃, it is forbidden to open the furnace chamber to avoid being hurt; | ||

Service Support | 1 year warranty with lifetime support (consumable parts are not included in the warranty) | ||

Disclaimer: The content of this site product introduction (including product images, product descriptions, technical parameters, etc.), is for reference only. May be due to the update is not timely, perhaps leading to the content of the said and the actual situation there are certain differences, please contact our customer service staff to confirm. The information provided on this site does not constitute any offer or commitment, Nobadi company from time to time to improve and modify any information on the site, without notice.

Related products

Configuration details

| Equipment features: | ||

Product Model | NBD-ML1200-10CI(Anti-corrosion type) | ||

Electrical Specifications | AC220V 1KW | ||

Reachable temperature | 1200℃(<1 hour) | ||

continuous temperature | 1100℃(progression) | ||

Reachable heating rate | ≤20℃/minutes | ||

Furnace size | 100*100*100mm | ||

control system |

| 1. Fuzzy PID temperature control, high brightness digital tube display; | |

Temperature control accuracy | +/- 1℃ | ||

Heating chamber |

| Fully enclosed alumina fibre chamber with embedded heating elements and enclosed armoured thermocouples | |

net weight | ≈10KG | ||

Precautions for the use of equipment | 1. When the temperature of the furnace chamber of the equipment is ≥300℃, it is forbidden to open the furnace chamber to avoid being hurt; | ||

Service Support | 1 year warranty with lifetime support (consumable parts are not included in the warranty) | ||

Disclaimer: The content of this site product introduction (including product images, product descriptions, technical parameters, etc.), is for reference only. May be due to the update is not timely, perhaps leading to the content of the said and the actual situation there are certain differences, please contact our customer service staff to confirm. The information provided on this site does not constitute any offer or commitment, Nobadi company from time to time to improve and modify any information on the site, without notice.

Related products

推荐产品

Manual button battery sealing machine

12L intelligent box furnace

Large capacity bottom-loading furnace

Production vacuum atmosphere pendulum rotary sintering furnace 1200℃

vacuum oven

High power PECVD system (Rotary Pendulum Vibration)

Hydrogen reduction integrated sintering furnace (1500 ℃)

Thermal insulation refractory product

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China