Glove box matching transition furnace

Release time: 2024-06-19 08:28:02 Number of views: 465

Equipment Introduction:

Glove box matching transition furnace is a highly integrated advanced material processing equipment, mainly used for the research and production of powder metallurgy, new material synthesis, precision ceramics, magnetic materials, and other fields that require strict control of atmosphere conditions. The design of this product is to achieve seamless connection from material processing, pretreatment to sintering process through a comprehensive system, ensuring the maintenance of oxygen free, anhydrous or other specific inert atmosphere environment throughout the entire process flow, in order to improve the performance and purity of the final product.

Configuration details

| Equipment features: | |||||||

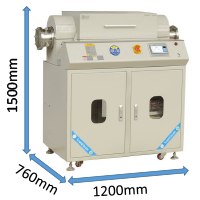

Device Name | Glove box matching transition sintering furnace | |||||||

Specification and model | NBD-O1200-152-T3D2FY00116 | |||||||

Tmax | 1150℃ | |||||||

Power supply | single-phase380V 50HZ | |||||||

Rated power | 12KW | |||||||

| Number of temperature zones | Single temperature dual control | |||||||

Temperature measuring element type | K-type thermocouple | |||||||

Temperature Zone One Size | φ150mm*300mm | |||||||

Temperature Zone 2 Size | φ150mm*300mm | |||||||

| heating rate | 1℃/H-20℃/Min | |||||||

Furnace body size | 1200*1500*760mm | |||||||

Opening and closing method | Dual electric push rod electric opening and closing | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set; | ||||||

Application instance shooting |  |  | ||||||

Temperature accuracy | ±1℃ | |||||||

Heating element |

| High temperature alloy wire | ||||||

Net weight | 150kg | |||||||

Equipment usage precautions | 1. When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury; | |||||||

Service support | One year limited warranty with lifetime support (warranty does not include consumable parts such as handling pipes and O-rings. Please order replacement parts at the relevant product section below.) | |||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

Related products

、

推荐产品

High pressure and high vacuum rotary pendulum sintering furnace

Anaerobic purification electrolytic furnace

Continuous cycle atmosphere protection automatic feeding and discharging system

Pilot scale molten salt electroplating furnace

1200 ℃ CVD integrated machine

Bottom-loading sintering furnace

Rotary pendulum oxidation furnace (silicon nitride tube)

Cooling circulator

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China