Three temperature zone PECVD system

Release time: 2024-06-18 09:22:57 Number of views: 453

The three temperature zone PECVD system, also known as the Plasma Enhanced Chemical Vapor Deposition (PECVD) system, is an advanced thin film deposition technology widely used in the semiconductor industry, microelectronics, optoelectronics, solar energy and other fields. The system converts the gas in the quartz vacuum chamber into an ionic state through an RF power supply, activates the reaction gas with high-energy electrons in the plasma, and causes it to undergo chemical reactions at lower temperatures, thereby depositing the required thin film on the substrate.

Configuration details

| Equipment features: | |||||||

| Specification and model① | NBD-O1200-TS3-4ZD-PE | |||||||

| name① | CVDsystem | |||||||

| Power supply | 380V 50HZ | |||||||

| Tmax | 1200℃ | |||||||

| Rated temperature | 1150℃ | |||||||

| Touch screen size | 7" | |||||||

| Temperature zone size | 200+200+200mm(Three temperature and three control) | |||||||

| Heating rated power | 9KW | |||||||

Sensor type | K-type thermocouple | |||||||

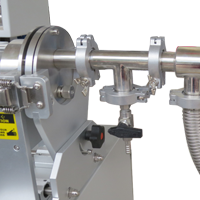

| Material and size of furnace tubes | Quartz tubeΦ80*1400mm | |||||||

heating rate | 1℃/H-20℃/Min | |||||||

Mechanical pump pumping rate | 6 cubic meters per hour KF25 | |||||||

| Maximum vacuum degree of furnace chamber | 3~5PaEquipped with digital vacuum gauge | |||||||

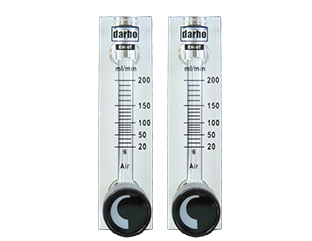

Air intake system | Four way mass flow controller100sccm 200sccm 500sccm 500sccm | |||||||

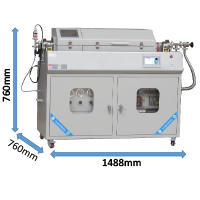

External dimensions of the furnace body | 1488 long * 1275 high * 760mm deep | |||||||

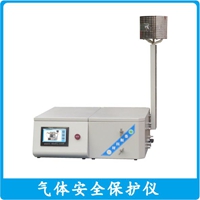

Specification and model② | RF-500W | |||||||

name② | Plasma generator | |||||||

RF frequency | 13.56MHz | |||||||

RF power output range | 0-500WAdjustable | |||||||

External dimensions | Length 275 * Height 380 * Depth 430mm | |||||||

| RF power | 500W | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set; | ||||||

Temperature accuracy | ±1℃ | |||||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, and has strong corrosion and high temperature resistance. | ||||||

Gas supply system |

|

| ||||||

| Equipment details |  |

| ||||||

Net weight | 280kg | |||||||

Equipment usage precautions | 1. When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury; | |||||||

Service support | One year limited warranty with lifetime support (warranty does not include consumable parts such as handling pipes and O-rings. Please order replacement parts at the relevant product section below.) | |||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

Related products

Configuration details

| Equipment features: | |||||||

| Specification and model① | NBD-O1200-TS3-4ZD-PE | |||||||

| name① | CVDsystem | |||||||

| Power supply | 380V 50HZ | |||||||

| Tmax | 1200℃ | |||||||

| Rated temperature | 1150℃ | |||||||

| Touch screen size | 7" | |||||||

| Temperature zone size | 200+200+200mm(Three temperature and three control) | |||||||

| Heating rated power | 9KW | |||||||

Sensor type | K-type thermocouple | |||||||

| Material and size of furnace tubes | Quartz tubeΦ80*1400mm | |||||||

heating rate | 1℃/H-20℃/Min | |||||||

Mechanical pump pumping rate | 6 cubic meters per hour KF25 | |||||||

| Maximum vacuum degree of furnace chamber | 3~5PaEquipped with digital vacuum gauge | |||||||

Air intake system | Four way mass flow controller100sccm 200sccm 500sccm 500sccm | |||||||

External dimensions of the furnace body | 1488 long * 1275 high * 760mm deep | |||||||

Specification and model② | RF-500W | |||||||

name② | Plasma generator | |||||||

RF frequency | 13.56MHz | |||||||

RF power output range | 0-500WAdjustable | |||||||

External dimensions | Length 275 * Height 380 * Depth 430mm | |||||||

| RF power | 500W | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set; | ||||||

Temperature accuracy | ±1℃ | |||||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, and has strong corrosion and high temperature resistance. | ||||||

Gas supply system |

|

| ||||||

| Equipment details |  |

| ||||||

Net weight | 280kg | |||||||

Equipment usage precautions | 1. When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury; | |||||||

Service support | One year limited warranty with lifetime support (warranty does not include consumable parts such as handling pipes and O-rings. Please order replacement parts at the relevant product section below.) | |||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

Related products

| |||

|

推荐产品

Glove box plus high temperature furnace, etc

1200°C Vacuum Atmosphere Chamber Furnace(27L)

Vacuum well furnace

Cooling circulator

Industrial rotary pendulum sintering furnace

Vertical HVPE single crystal growth system

.jpg)

3000℃ ultra-high temperature atmosphere furnace

Mesh belt brazing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China