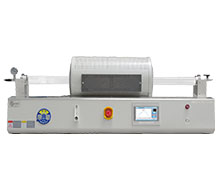

Extended sliding rail mobile fast annealing furnace

Release time: 2024-06-05 16:32:17 Number of views: 311

Introduction to Vacuum Atmosphere Circulating Annealing Furnace Equipment:

The extended sliding rail mobile rapid annealing furnace is a heating equipment designed for efficient and continuous production and heat treatment processes. With its flexibility, high efficiency, continuity, and fast processing ability, it has become one of the important equipment for material heat treatment in modern industrial production and scientific research. It is particularly suitable for material treatment scenarios that require rapid heating and cooling cycles, such as metal heat treatment, ceramic sintering, glass annealing, etc.

| Equipment features: | ||

Device Name | Quick annealing furnace | ||

Specification and model | NBD-CMT1200-60TI+ | ||

Power supply | single-phase220V 50HZ | ||

Rated power | 4KW | ||

Number of temperature zones | Single temperature and single control | ||

control accuracy | ±1℃ | ||

Sensor type | K-type thermocoupleΦ1*500mm | ||

maximum temperature | 1150℃ | ||

Furnace tube material | quartzΦ60*1400mm | ||

heating rate | 1℃/H-20℃/Min | ||

Temperature zone size length | Φ150*430mm | ||

Furnace body size | 1520 long x 520 high x 550mm deep | ||

Heating element | High temperature resistance wire | ||

control system | 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set; | ||

Temperature accuracy | ±1℃ | ||

Heating element | | Mo doped Fe Cr Al alloy | |

Pressure measurement and monitoring | | Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, and has strong corrosion and high temperature resistance. | |

Gas supply system |

| The gas flow rate is controlled by a float flowmeter, integrated with the equipment, and leak testing has been carried out before leaving the factory. | |

Net weight | 100kg | ||

Equipment usage precautions | 1. When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury; 2. When using the equipment, the pressure inside the furnace tube should not exceed 0.125MPa (absolute pressure) to prevent equipment damage caused by excessive pressure; 3. When used under vacuum, the operating temperature of the equipment shall not exceed 800 ℃. 4. The internal pressure of the gas supply steel cylinder is relatively high. When gas is introduced into the furnace tube, a pressure reducing valve must be installed on the cylinder. It is recommended to purchase a small pressure reducing valve for testing, with a range of 0.01MPa-0.15MPa, which will be more precise and safe to use. 5. When the temperature of the furnace body exceeds 1000 ℃, the furnace tube cannot be in a vacuum state, and the air pressure inside the furnace tube must be equivalent to atmospheric pressure and maintained at atmospheric pressure; 6. Long term use temperature of high-purity quartz tube ≤ 1100 ℃ 7. It is not recommended to close the exhaust valve and intake valve at the flange end of the furnace tube during heating experiments. If it is necessary to close the gas valve to heat the sample, it is necessary to always pay attention to the reading on the pressure gauge. The absolute pressure gauge reading should not exceed 0.15MPa. The exhaust end valve must be immediately opened to prevent accidents (such as furnace tube rupture, flange flying out, etc.). | ||

Service support | One year limited warranty with lifetime support (warranty does not include consumable parts such as handling pipes and O-rings. Please order replacement parts at the relevant product section below.) | ||

推荐产品

Oscillating ball mill mixer

Mini well-type furnace

Vacuum storage cabinet

Small CVD system

Well type melting furnace 0.45L1200℃

Industrial rotary pendulum sintering furnace

NBD-103(B) Vacuum system

Openable vertical tube furnace 1200℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China