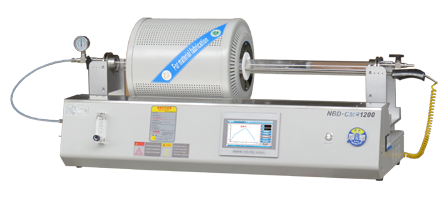

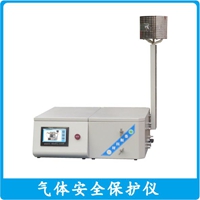

Sliding rail mobile fast annealing furnace

Release time: 2024-06-05 16:18:10 Number of views: 258

Equipment Introduction:

The equipment adopts a shortwave infrared radiation heater, which can quickly heat up, with a heating rate of 100 ℃/sec. The chamber automatically moves left and right to achieve rapid cooling. After sintering, the furnace moves away from the sample placement area to achieve rapid cooling of the sample.

Configuration details

| Equipment features: | |||

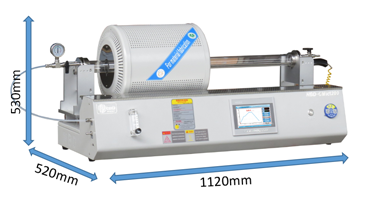

Product model | NBD-CHR1200-60TI | NBD-CHR1200-80TI | NBD-CHR1200-100TI | |

Furnace tube size | Φ60*1000mm | Φ80*1000mm | Φ100*1000mm | |

Heating zone length | 200mm (Constant temperature zone150mm) | |||

Electrical specifications | 3相 AC380V 15KW | |||

Reachable temperature | 1150℃(<1hour) | |||

Continuous temperature | 1100℃(continuity) | |||

Reachable heating rate | ≤ 100 ℃/sec | |||

Temperature accuracy | +/- 1 ℃ | |||

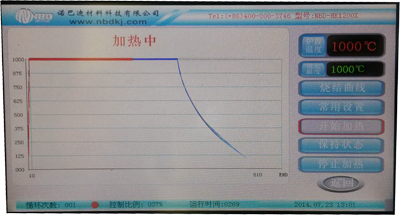

Temperature field distribution |

| As shown in the figure: This is the temperature range curve of the device | ||

control system |

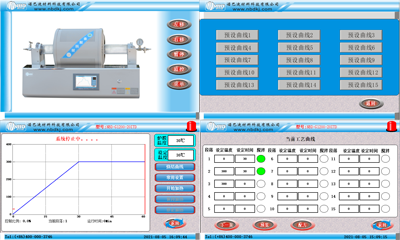

| 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set; 2. Can schedule sintering and achieve unmanned sintering process curve sintering; 3. Real time display of sintering power and voltage information, recording sintering data, and export to achieve paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is corrected nonlinearly throughout the sintering process. | ||

Heating element |

| The system adopts a short wave infrared heater with a power of 1.1~1.5um, which has high efficiency and does not directly contact the surface of objects. It does not need to pass through any medium and conducts high energy by releasing electromagnetic rays, achieving the goal of rapid heating. | ||

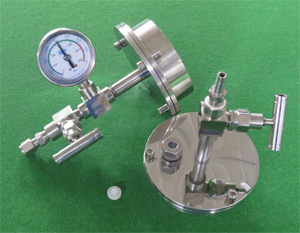

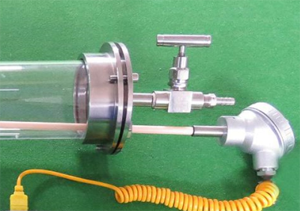

Sealing system |

|

| ||

Optional: Vacuum degree: ≤ 10Pa (mechanical pump) ≤ 3.5 * 10-3Pa (f molecular pump unit) | ||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge with shock-absorbing oil can prevent damage to the gauge pointer. | ||

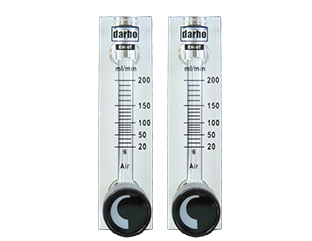

Gas supply system |

| Adopting float flow meter control, integrated with equipment for easy control, leak testing has been carried out before leaving the factory. | ||

Equipment usage precautions | 1、When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury; | |||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

Related products

Configuration details

| Equipment features: | |||

Product model | NBD-CHR1200-60TI | NBD-CHR1200-80TI | NBD-CHR1200-100TI | |

Furnace tube size | Φ60*1000mm | Φ80*1000mm | Φ100*1000mm | |

Heating zone length | 200mm (Constant temperature zone150mm) | |||

Electrical specifications | 3相 AC380V 15KW | |||

Reachable temperature | 1150℃(<1hour) | |||

Continuous temperature | 1100℃(continuity) | |||

Reachable heating rate | ≤ 100 ℃/sec | |||

Temperature accuracy | +/- 1 ℃ | |||

Temperature field distribution |

| As shown in the figure: This is the temperature range curve of the device | ||

control system |

| 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set; 2. Can schedule sintering and achieve unmanned sintering process curve sintering; 3. Real time display of sintering power and voltage information, recording sintering data, and export to achieve paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is corrected nonlinearly throughout the sintering process. | ||

Heating element |

| The system adopts a short wave infrared heater with a power of 1.1~1.5um, which has high efficiency and does not directly contact the surface of objects. It does not need to pass through any medium and conducts high energy by releasing electromagnetic rays, achieving the goal of rapid heating. | ||

Sealing system |

|

| ||

Optional: Vacuum degree: ≤ 10Pa (mechanical pump) ≤ 3.5 * 10-3Pa (f molecular pump unit) | ||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge with shock-absorbing oil can prevent damage to the gauge pointer. | ||

Gas supply system |

| Adopting float flow meter control, integrated with equipment for easy control, leak testing has been carried out before leaving the factory. | ||

Equipment usage precautions | 1、When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury; | |||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

Related products

| |||

|

推荐产品

Vertical homogenization melting furnace

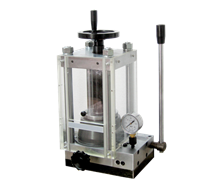

Manual tablet press

Bottom-loading high temperature sintering furnace

Multi-function high temperature pit furnace

Multi channel liquid gas-phase generator

Vertical high-temperature tube furnace (Type 1)

.png)

MiNi wax removal prefiring furnace

25 station vacuum atmosphere tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China