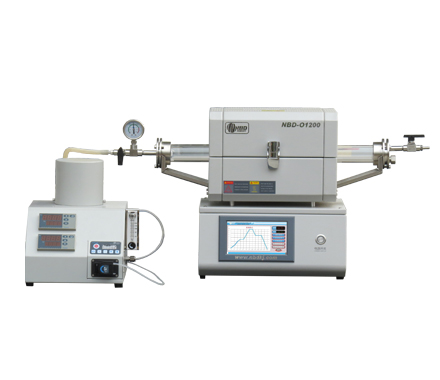

High temperature vertical rapid pyrolysis furnace

Release time: 2024-05-14 13:53:21 Number of views: 391

Equipment Introduction:

| Equipment features: achieve continuous feeding. The discharge collection silo can choose different pore sizes of filter screens according to the size of the material. The current filter screen aperture of the equipment is 100 mesh, and the filter screen adopts a detachable structure, which greatly facilitates customer cleaning and replacement in the later stage. which can realize the feeding of materials at high temperatures. After a brief sintering treatment in the high-temperature area, the materials are collected in the collection bin below. and modification treatment of magnetic materials. The small size and small footprint of the equipment make it particularly suitable for the needs of laboratory customers.

| |||||||

Equipment model | NBD-LT1700-60TI | |||||||

control accuracy | ±1℃ | |||||||

T-max | 1700℃ | |||||||

Touch screen size | 7" | |||||||

Rated power | 10KW | |||||||

Sensor type | B型Φ8*150mm | |||||||

| Rated temperature | 1650℃ | |||||||

| Temperature zone size | Φ220*310mm | |||||||

| Heating element | High purity silicon molybdenum rod | |||||||

heating rate | 1℃/H-20℃/Min | |||||||

| Furnace tube size | Corundum tubeΦ60*1000mm | |||||||

| Volume of feed silo | 80ml | |||||||

Volume of discharge collection silo | 1.5L(100目过滤网) | |||||||

Extract the size of the vacuum opening | KF25 | |||||||

| Size of water-cooled pipes | PU TubeΦ10*6.5 | |||||||

| Intake pipe size | PTFE tubeΦ6.35 | |||||||

| Exhaust pipe size | Silicone tubeΦ6-Φ12mm | |||||||

| ball valve | High temperature hard sealed ball valve DN50 | |||||||

| inlet | One path of float flow machine intake is connected to the feeding bin, with one path reserved for intake | |||||||

| Float flowmeter size | 20-200ml/min | |||||||

| Net size of furnace body shape | 1080 length*2000 height*600mm depth | |||||||

weight | ≈220KG | |||||||

Equipment Details 1 |

| High temperature resistant hard sealed ball valve, capable of delivering materials at high temperatures. | ||||||

| Equipment Details 2 |

| Collect materials in the collection bin after a brief sintering treatment in the high-temperature area | ||||||

| control system |   | 1. 15 temperature curves can be pre stored to avoid the trouble caused by repeated settings of different experimental processes;

| ||||||

Heating element |

| High purity silicon molybdenum rod | ||||||

Vacuum degree: 10Pa (mechanical pump) | ||||||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, while also having strong corrosion and high temperature resistance capabilities | ||||||

Gas supply system |   | The gas flow rate is controlled by a float flowmeter, which is integrated wit h the equipment and has undergone leak testing before leaving the factory. | ||||||

Equipment usage precautions |

When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure;When used under vacuum, the operating temperature of the equipment shall not exceed 800 ℃.

| |||||||

Service support | as handling pipes and O-rings. Please order replacement parts at the relevant product section below.) | |||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

| Equipment features: achieve continuous feeding. The discharge collection silo can choose different pore sizes of filter screens according to the size of the material. The current filter screen aperture of the equipment is 100 mesh, and the filter screen adopts a detachable structure, which greatly facilitates customer cleaning and replacement in the later stage. which can realize the feeding of materials at high temperatures. After a brief sintering treatment in the high-temperature area, the materials are collected in the collection bin below. and modification treatment of magnetic materials. The small size and small footprint of the equipment make it particularly suitable for the needs of laboratory customers.

| |||||||

Equipment model | NBD-LT1700-60TI | |||||||

control accuracy | ±1℃ | |||||||

T-max | 1700℃ | |||||||

Touch screen size | 7" | |||||||

Rated power | 10KW | |||||||

Sensor type | B型Φ8*150mm | |||||||

| Rated temperature | 1650℃ | |||||||

| Temperature zone size | Φ220*310mm | |||||||

| Heating element | High purity silicon molybdenum rod | |||||||

heating rate | 1℃/H-20℃/Min | |||||||

| Furnace tube size | Corundum tubeΦ60*1000mm | |||||||

| Volume of feed silo | 80ml | |||||||

Volume of discharge collection silo | 1.5L(100目过滤网) | |||||||

Extract the size of the vacuum opening | KF25 | |||||||

| Size of water-cooled pipes | PU TubeΦ10*6.5 | |||||||

| Intake pipe size | PTFE tubeΦ6.35 | |||||||

| Exhaust pipe size | Silicone tubeΦ6-Φ12mm | |||||||

| ball valve | High temperature hard sealed ball valve DN50 | |||||||

| inlet | One path of float flow machine intake is connected to the feeding bin, with one path reserved for intake | |||||||

| Float flowmeter size | 20-200ml/min | |||||||

| Net size of furnace body shape | 1080 length*2000 height*600mm depth | |||||||

weight | ≈220KG | |||||||

Equipment Details 1 |

| High temperature resistant hard sealed ball valve, capable of delivering materials at high temperatures. | ||||||

| Equipment Details 2 |

| Collect materials in the collection bin after a brief sintering treatment in the high-temperature area | ||||||

| control system |   | 1. 15 temperature curves can be pre stored to avoid the trouble caused by repeated settings of different experimental processes;

| ||||||

Heating element |

| High purity silicon molybdenum rod | ||||||

Sealing system |

|  |

| |||||

Vacuum degree: 10Pa (mechanical pump) | ||||||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, while also having strong corrosion and high temperature resistance capabilities | ||||||

Gas supply system |   | The gas flow rate is controlled by a float flowmeter, which is integrated wit h the equipment and has undergone leak testing before leaving the factory. | ||||||

Equipment usage precautions |

When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure;When used under vacuum, the operating temperature of the equipment shall not exceed 800 ℃.

| |||||||

Service support | as handling pipes and O-rings. Please order replacement parts at the relevant product section below.) | |||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

推荐产品

Bridgman crystal growth furnace

CVD system T1500-XTID3Z

Liquid-gas CVD all-in-one machine

Steam generator for tube furnaces

Cold wall rapid annealing furnace

Meltblowout cloth nozzle anaerobic cleaning furnace 1200℃

Industrial vertical kiln

Vertical double tube sintering furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China