Three temperature zone gradient furnace

Release time: 2024-05-10 14:28:30 Number of views: 323

Equipment Introduction:

To meet the requirements of various CVD processes, we have integrated control instruments from multiple temperature zones into the intelligent control system for the three temperature zone gradient furnace. You only need to lightly click on the touch screen to complete all parameter settings. While satisfying the gradient control of different temperature zones, multiple temperature zones can also be set to the same temperature point for use as extended single temperature zones. It continues the classic design of an open tube furnace, combining aesthetics and practicality!

| Equipment features: | ||

Product model | NBD-O1200-50T3GF | ||

Tmax | 1200℃ | ||

Rated temperature | 1150℃ | ||

Power supply | 220V 50HZ | ||

Rated power | 2.6KW | ||

| Temperature zone length | 100+200+100mm | ||

Long term use temperature range | 300-1150℃ | ||

Number of temperature zones | Three temperature single control | ||

heating rate | 1℃/H-20℃/Min | ||

Sensor type | K-type thermocouple | ||

Furnace tube length | 50*1000mm | ||

Furnace body size | Length 600 * Height 550 * Depth 370mm | ||

control system |

| 1. 15 temperature curves can be pre stored to avoid the trouble caused by repeated settings of different experimental processes; 2. The experimental process is more intuitive and the operation is more convenient; | |

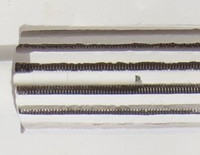

| Heating element |  | Mo doped Fe Cr Al alloy | |

Sealing system |  |

Vacuum degree: 10Pa (mechanical pump) | |

Pressure measurement and monitoring |  | Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, and has strong corrosion and high temperature resistance. | |

| Gas supply system |  | The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | |

control accuracy | +/- 1℃ | ||

Net weight | ≈48KG | ||

Equipment usage precautions | 1. When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury; | ||

Service support | 1-year warranty with lifetime support (excluding consumables) | ||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice

推荐产品

Medium frequency induction alloy sublimation furnace

Battery Tester 5V100mA Quad Range (BT-2018R)

High temperature and high pressure tube furnace

High Flux Intelligent Chamber Furnace

Large high temperature vacuum atmosphere muffle furnace

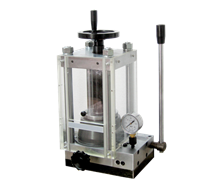

Manual tablet press

Vacuum molten salt electroplating furnace

Anti-corrosion mini chamber furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China