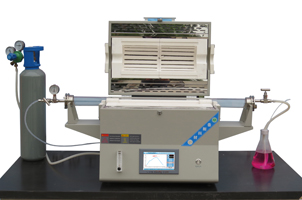

Large scale multi temperature zone vacuum tube furnace

Release time: 2024-05-10 08:39:16 Number of views: 291

Equipment Introduction:

This device is a specialized equipment developed for higher education institutions, research institutes, and industrial and mining enterprises to sinter, melt, and analyze metal, non-metal, and other compound materials under vacuum or atmosphere conditions. It adopts PLC control and touch screen operation. You only need to lightly click the touch screen to complete all parameter settings, and can also meet the needs of various CVD processes.

| Equipment features: | |||||||||||||||

Product model | NBD-O1200-152T3D2FY-200 | |||||||||||||||

Power supply | Three phase 380V 50HZ | |||||||||||||||

Rated power | 20KW | |||||||||||||||

Heating element | High quality iron chromium aluminum alloy wire | |||||||||||||||

control accuracy | ±1℃ | |||||||||||||||

Temperature measuring element type | K-type thermocouple | |||||||||||||||

Tmax | 1150℃ | |||||||||||||||

Long term use temperature range | 300~1150℃ | |||||||||||||||

Heating temperature zone size | φ200*(300+400+300)mm | |||||||||||||||

Furnace tube material | High purity quartz tube | |||||||||||||||

Furnace body size | Length 2000 x Depth 770 x Height 1300mm | |||||||||||||||

heating rate | 1℃/H-20℃/Min | |||||||||||||||

Equipment ultimate vacuum degree | 10pa | |||||||||||||||

weight | 约400kg | |||||||||||||||

| Sealing system |    | |||||||||||||||

| Mechanical control interface |

| |||||||||||||||

The tubular high-temperature sintering furnace consists of the following parts | ▲ Sintering system: The sintering system adopts a resistance wire ring heating method, which makes the temperature range more uniform and uses K-type thermocouples for temperature control; | |||||||||||||||

Heating chamber |  | |||||||||||||||

Gas path control (two float flow meters) |  | |||||||||||||||

* Support non-standard customization, more models, welcome to call for inquiries:400-000-3746 | ||||||||||||||||

免责声明Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

推荐产品

High temperature, high pressure automatic feeding tube furnace

Full bridge crystallizing furnace

Single temperature zone tube furnace 1200℃

1.5C vacuum pump

High temp. hydrogen vibrating plate sintering furnace

Vertical quenching furnace

System O1200-XT22D2F

Vacuum graphite heating furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China