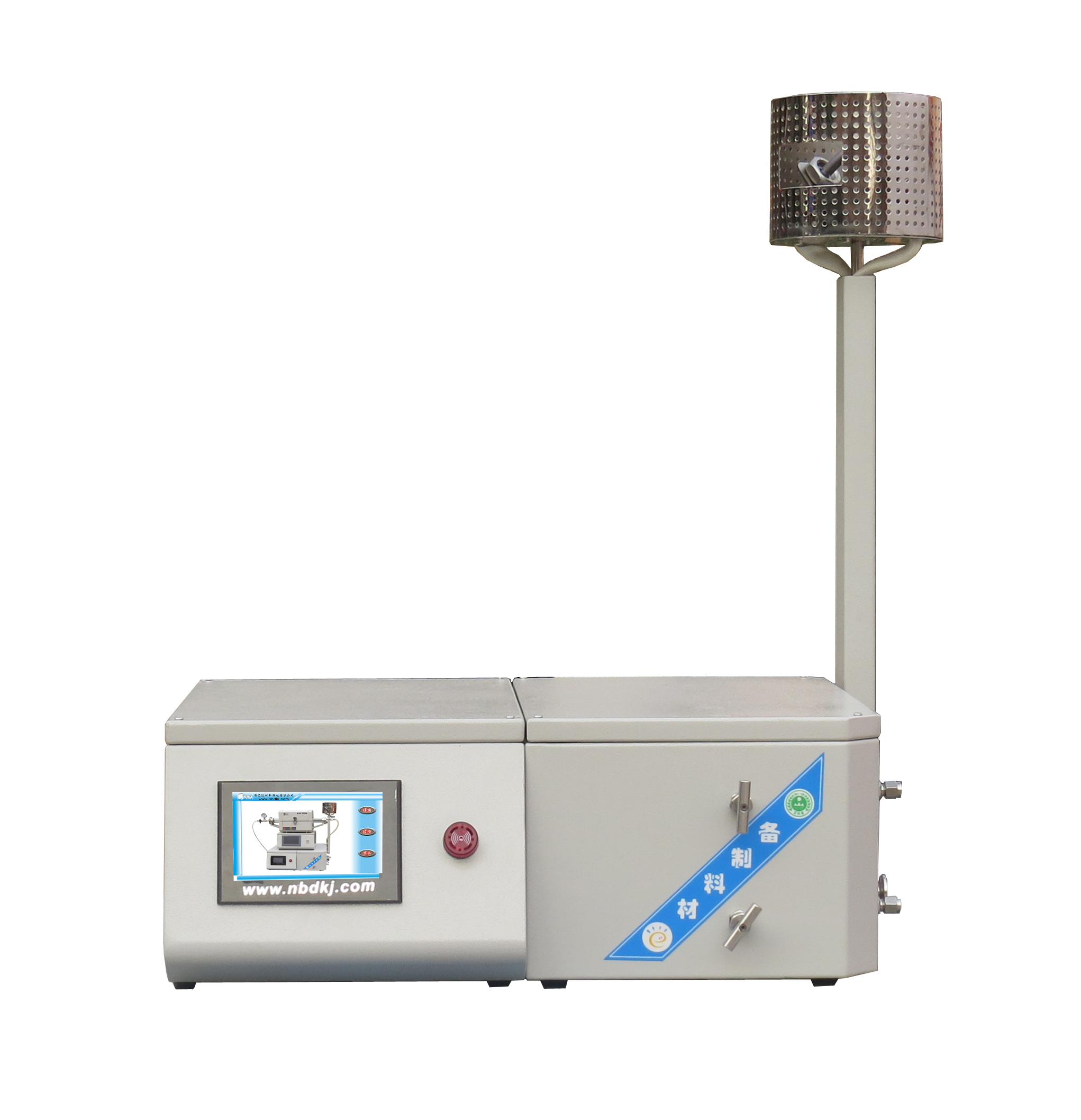

Three temperature zone vertical tube furnace (fluidized bed FBCVD furnace)

Release time: 2024-05-06 14:29:41 Number of views: 390

Equipment Introduction:

A three temperature zone vertical tube furnace using Fluidized Bed Chemical Vapor Deposition (FBCVD) technology. FBCVD technology is carried out in the fluidized bed area of the furnace, where solid particles exhibit a state similar to liquid boiling under the action of rising gas flow. This not only increases the contact area between materials and reaction gases, but also promotes uniform heating and efficient conversion of reactants. It is commonly used to prepare various materials such as thin films and powders.

In addition to possessing the basic characteristics of a typical three temperature zone tube furnace, this equipment has also been optimized for fluidized bed reactions, such as enhancing gas flow and distribution, ensuring stable fluidized bed conditions in the fluidized bed area, etc. In practical applications, it can be used for the growth of advanced materials such as carbon nanotubes and graphene, as well as the preparation and modification of catalysts.

| Equipment characteristics 1. High temperature sintering. | |||||||

Device Name | Three temperature zone vertical tube furnace (fluidized bed FBCVD) | |||||||

Specification and model | NBD-OP1200-LT3 | |||||||

Tmax | 1150℃ | |||||||

Power supply | Three phase 380V 50HZ | |||||||

Rated power | 8KW | |||||||

Number of temperature zones | Three temperature and three control | |||||||

Temperature control accuracy | ±1℃ | |||||||

| Sensor type | K-type thermocouple | |||||||

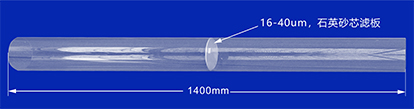

| Temperature zone size | φ150*900mm | |||||||

| Furnace body size | 1100 long*1970 high*670mm deep | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set; | ||||||

| Equipment Details |  | |||||||

Temperature Accuracy | ±1℃ | |||||||

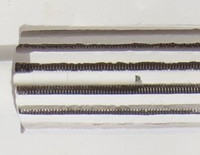

heating element |

| Mo doped Fe Cr Al alloy | ||||||

Vacuum degree: 10Pa (mechanical pump) | ||||||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, and has strong corrosion and high temperature resistance. | ||||||

Gas supply system |

| The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | ||||||

Weakly corrosive gas preheater (Optional) |  | The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃. | ||||||

Net weight | 约260KG | |||||||

Equipment usage precautions | When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure; | |||||||

Service support | One year limited warranty with lifetime support (warranty does not include consumable parts such as handling pipes and O-rings. Please order replacement parts at the relevant product section below.) | |||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

Related products

推荐产品

Open Mini Rotary Stove

Industrial annealing sintering furnace

High power PECVD system (Rotary Pendulum Vibration)

Φ95×50mm corundum crucible

1500 ℃ (80L) ultra large capacity box furnace

Anaerobic hot dip plating (quenching) system

Universal testing machine with heating furnace (Type B)

Gas safety protection device for tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China