Dual temperature and dual control tube furnace

Release time: 2024-05-06 14:09:47 Number of views: 584

The intelligent dual temperature zone tube furnace has the advantages of temperature field balance, low surface temperature, fast temperature rise and fall rate, and energy saving. It is an ideal product for universities, research institutes, and industrial and mining enterprises to conduct high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, and vacuum annealing. The furnace adopts a multi-point temperature control method to ensure the uniformity of temperature inside the furnace and effectively improve the experimental effect。

| Equipment features:

| |||||||

Device Name | Dual temperature and dual control tube furnace | |||||||

source | Single phase 220V 50HZ | |||||||

Rated power | 6KW | |||||||

| Temperature measuring element type | S-type thermocouple φ 8 * 205mm | |||||||

| Tmax | 1450℃ | |||||||

| Heating temperature zone size | First temperature zone:Φ100*225mm Second temperature zone:Φ100*225mm | |||||||

| Furnace tube size | Φ100*1200mm | |||||||

| External dimensions | 1414mm long x 720mm high x 514mm deep | |||||||

| Heating rate | 1℃/H-20℃/Min | |||||||

| weight | 350kg | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set;

| ||||||

Temperature accuracy | ±1℃ | |||||||

Heating element | High purity silicon carbon rods with superior acid and corrosion resistance | |||||||

Sealing system |

|

|

| |||||

Vacuum degree: 10Pa (mechanical pump) | ||||||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, and has strong corrosion and high temperature resistance.

| ||||||

Gas supply system | | The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory.

| ||||||

Net weight | 350kg | |||||||

Equipment usage precautions |

1. When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury;

| |||||||

Service support | One year limited warranty with lifetime support (warranty does not include consumable parts such as handling pipes and O-rings. Please order replacement parts at the relevant product section below.) | |||||||

推荐产品

1500℃ large capacity muffle furnace

Anaerobic hot dip plating (quenching) system

Box Type Thermogravimetric Analyser (TGA)

Thermal insulation refractory product

Hydrogen reduction furnace with smooth bore

Vertical five sided heating furnace 1200 ℃

Desktop type Glove box

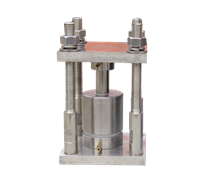

Solid state battery pressure insulation mold set

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China