Vertical vacuum atmosphere furnace(clean type)

Release time: 2023-06-01 17:19:10 Number of views: 510

Equipment introduction:

This series of vacuum atmosphere furnace uses high purity quartz reaction chamber, which can achieve high vacuum conditions. Wrap type surround heating, fast heating, accurate temperature control, uniform temperature field.

It is widely used in the heat treatment of cemented carbide, ceramics, powder metallurgy and other materials in rough vacuum, reductive atmosphere and protective atmosphere. In addition, the touch screen control system independently developed by our company can improve work efficiency. The furnace can be customized according to the actual needs of users.

Configuration

| Equipment features: | ||||||

Model | NBD-VAH1200-30TIF | ||||||

Electrical Spec | AC380V 10KW | ||||||

Heating element | High quality iron chrome aluminum alloy wire | ||||||

Temp Accuracy | ±1℃ | ||||||

Thermocouple type | K-type | ||||||

Tmax | 1100℃ | ||||||

heating chamber size | φ300*690mm | ||||||

chamber size | L1100×D1100×H1650mm | ||||||

Heating rate | ≤10℃/min | ||||||

System vacuum | 10Pa | ||||||

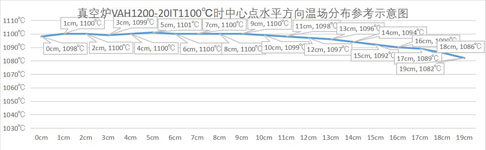

temperature field distribution |

| This is the temperature zone diagram of the device | |||||

Control system |

| 1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; 2, can be reserved sintering, to achieve unattended sintering process curve sintering; 3, real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless recording; 4, with remote control, real-time observation of equipment status; 5, temperature correction: the difference between the main control temperature and the sample temperature, the whole sintering process for nonlinear correction. | |||||

Temp Accuracy | +/- 1 ℃ | ||||||

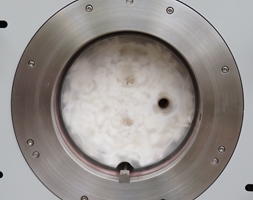

石英腔体 |

| ||||||

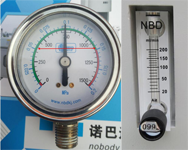

Gas supply system and pressure measurement |

| Mechanical pressure gauge with damping oil, and 1 small flow high-precision float flowmeter | |||||

| Quartz door plug |  |  | |||||

Net weight | Approx.300KG | ||||||

Cautions | 1. When the equipment is used, the pressure in the furnace tube shall not exceed 0.15MPa (absolute pressure) to prevent damage to the equipment caused by excessive pressure; | ||||||

Service | 2-year limited warranty with lifetime support (warranty does not cover consumable parts such as quartz cavities and O-rings) | ||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

Homogeneous oxidation diffusion furnace (Type I)

Battery Tester 5V100mA Quad Range (BT-2018R)

Well type melting furnace 0.45L1200℃

Three temperature zone PECVD system

Large capacity muffle furnace 1700℃

Large scale multi temperature zone vacuum tube furnace

Microwave sintering furnace Microwave box type furnace

Oscillating ball mill mixer

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China