Homogeneous diffusion furnace

Release time: 2023-04-06 09:00:08 Number of views: 984

Equipment introduction:

Colleges and universities, scientific research institutes and industrial and mining enterprises to metal, non-metal and other compound materials in the atmosphere state sintering, deposition, analysis and development of special equipment, it uses PLC control, touch screen operation. It is composed of sintering system, electronic control system, vacuum system and gas inlet and outlet system.

Configuration

| Equipment features: | ||||||

Model | NBD-T1200-215T3D3ZY | ||||||

Electrical Spec | Three-phase 380V 50HZ | ||||||

Rated power | 26KW | ||||||

Heating element | High quality iron chrome aluminium alloy wire | ||||||

Feeding mode | Hand feed | ||||||

Type of temperature measuring element | Type K thermocouple 420mm | ||||||

Tmax | 1150℃ | ||||||

Effective heating zone size | φ200*1300mm | ||||||

Tube material | High purity quartz | ||||||

Three-way gas flow | 2000ml/min,2000ml/min,10000ml/min | ||||||

Chamber size | L2300(3080)×D940×H1850mm | ||||||

Recommended heating rate | 10℃/min | ||||||

Net weight | 约550KG | ||||||

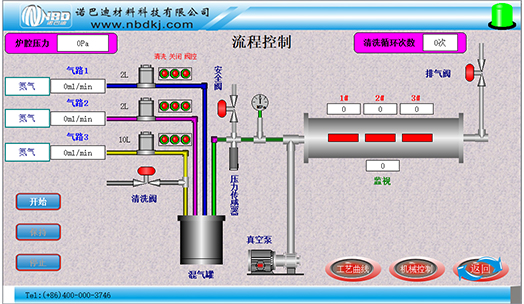

Flow control interface |

| ||||||

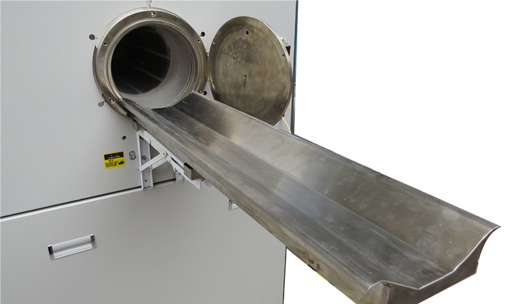

| Heating chamber |  | ||||||

| feeding port |  | ||||||

Service | One year limited warranty with lifetime support (warranty does not cover consumable parts such as furnace tubes and seals). | ||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

electric tablet machine

Universal testing machine with heating furnace (Type A)

Mini vacuum atmosphere furnace (box tube furnace)

Intelligent muffle furnace (12L)1200℃

(non) metal evaporation purification system

Thermogravimetric analysis (TGA) and condensation collection systems

0.35L melting furnace 1600℃

Box type crystallizing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China