Anticorrosive mini muffle furnace

Release time: 2023-01-14 13:49:47 Number of views: 579

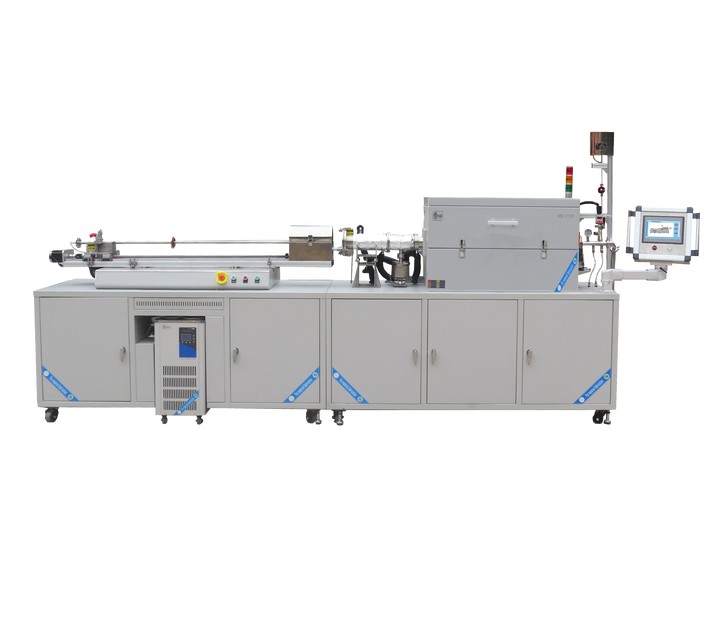

Equipment introduction:

On the basis of the original structure, the anticorrosive mini box furnace adopts a fully enclosed alumina fiber furnace with embedded heating elements, and a closed armored thermocouple, which can avoid the influence of high temperature precipitation of heating elements on the experimental results, and can effectively improve the service life of heating elements.

Scientific and reasonable lower open the door structure, the material can be taken out, can be directly placed on the furnace door, avoid burning workbench. It has exquisite shape and compact volume, is widely used in universities, scientific research institute laboratories, directly into the glove box, three sides of the uniform distributed heating, effectively enhance the furnace temperature field uniformity.

Configuration

| 1. Fully enclosed alumina fiber furnace with embedded heating element, enclosed armored thermocouple; | ||

Model | NBD-ML1200-10CI(Antiseptic type) | ||

Electrical Spec | AC220V 1KW | ||

Tmax | 1100℃ | ||

Heating rate | ≤20℃/min | ||

Chamber size | 100*100*100mm | ||

Control system |

| 1. Fuzzy PID temperature control, highlighting digital tube display; | |

Temp Accuracy | +/- 1℃ | ||

Furnace chamber |

| Fully enclosed alumina fiber furnace with built-in heating element, and enclosed armoured thermocouple. | |

Net weight | Approx.10KG | ||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | ||

Service | 1 year warranty with lifetime support (consumable parts not included). | ||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

Vertical quenching furnace

Dual-channel K-type digital thermometer

Heating-zone automatic tester

Extended tube furnace with single temperature zone 1500℃

Automatic hydrogen reduction furnace Type III

Push-pull tube sintering furnace

3-way mass gas proportioner

Anaerobic well type sintering furnace (glove box + well type furnace)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China