Safe automatic frit furnace

Release time: 2022-12-21 09:21:52 Number of views: 764

Equipment introduction:

PL series safety automatic vertical frit furnace, the whole adopts the international advanced manufacturing technology, the furnace is made of high purity alumina light fiber material, the control interface uses a large size touch screen, fool operation. The container adopts zircon quartz crucible, which has good resistance to high temperature and thermal shock. It can ensure the consistency of the quality of your samples. It is mainly used for colleges and universities and scientific research units to melt metal materials (such as stainless steel, nickel base alloy, copper, alloy steel, nickel cobalt alloy, rare earth neodymium iron, etc.) under vacuum or protective atmosphere. It can also be used for vacuum refining and precision casting of alloy steel.

Configuration

| 1, the furnace lining uses vacuum forming high-purity alumina poly light material, the surface is coated with high reflectivity ultra-high temperature coating, zircon quartz crucible placed in the middle of the furnace, in addition to maintaining the minimum loss of energy, but also to enhance the stability of high temperature performance, will not indirectly pollute the sample. | ||

Model | NBD-PL1700-5LTI | ||

Electrical Spec | 3-phase AC380V | ||

Tmax | 1650℃ | ||

Heating rate | ≤10℃/min | ||

Zirconium crucible volume | 5L;(1.6L,3L,5L,10L,17L and other specifications are available) | ||

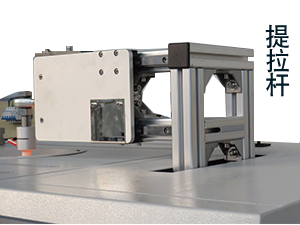

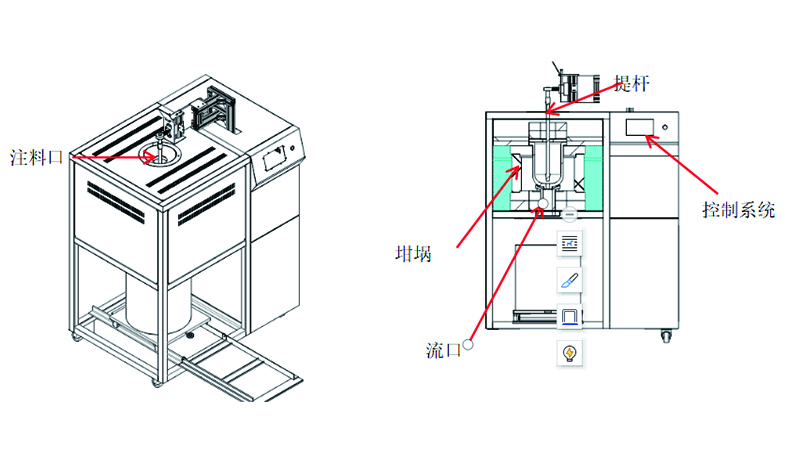

| Equipment details |   | ||

Crucible material |

| Adopt high purity zircon quartz crucible, high temperature resistance and good thermal shock resistance. | |

Temp Accuracy | +/- 1℃ | ||

Heating element |

| High purity silicon molybdenum rod | |

Control system |  | 1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated Settings of different experimental processes; | |

Net weight | 400KG | ||

Cautions | After melting, when taking out the plug, be sure to wear high temperature gloves to avoid injury; | ||

Service | 1 year warranty with lifetime support (warranty does not include consumable parts). | ||

Equipment structure drawing

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

PECVD plasma chemical vapor deposition system

Pressure rotary tube furnace

Well sintering furnace 1500/1700℃

Uniform temperature heating platform

Zirconia crystallizing furnace

Homogeneous diffusion furnace

CMT furnace sliding rail tube furnace 1200℃

Meltblowout cloth nozzle anaerobic cleaning furnace 1200℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China