High pressure tube furnace

Release time: 2022-12-12 10:16:27 Number of views: 883

Equipment introduction:

NBD-HP1200 double temperature zone high temperature and high pressure tubular furnace, in the flange installed with high pressure solenoid valve, pressure sensor and analog safety protection. Three more layers of security, so you don't have to worry. When the pressure in the chamber is higher than the set value, the electromagnetic vent valve will automatically open the exhaust, so that the pressure in the tube reaches the set value. This model can be used for heat treatment of the sample in the high pressure atmosphere gas environment, the highest temperature can reach 1150℃, suitable for the exploration of superconductivity and dielectric materials.

Configuration

1. Three layers of security protection let you work in peace; | |||||||||||||

Model | NBD-HP1200-3260T22ZY150 | ||||||||||||

| Electrical Spec | AC220V 50HZ 4.0KW | ||||||||||||

Temp Accuracy | ±1℃ | ||||||||||||

Rated power | 4.0KW | ||||||||||||

| Sensor type | Type K thermocouple | ||||||||||||

| Tmax | 1200℃ | ||||||||||||

| Rated temperature | 1150℃ | ||||||||||||

| Tube diameter | 60*1030mm | ||||||||||||

| Chamber size | L1300×D550×H610mm | ||||||||||||

| Heating rate | 10℃/min | ||||||||||||

Temperature allowable pressure | Temperature varies with air pressure. Please refer to the table below for details:

(Heat up first, then slowly into the gas, do not pass into the required pressure, as the temperature increases, the pressure will be more and more) | ||||||||||||

furnace construction | 1. Can open double-layer structure, conducive to the need for rapid cooling customers, shell surface temperature is less than 60℃ | ||||||||||||

Gas and crucible are available | 1. Oxidation, protective atmosphere and inert gases, such as N2, Ar and He. | ||||||||||||

Control system |

| 1. 15 temperature curves can be pre-stored, and 30 sections of "temperature-time" axis can be set for each curve, avoiding the trouble caused by repeated setting of different experimental processes; | |||||||||||

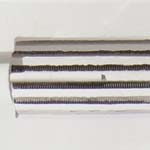

Heating element |

| Ferric chromium alloy doped molybdenum | |||||||||||

Pressure detection and control |

| 1. The high pressure chamber is installed with a pressure sensor, and connected with the control system, real-time display | |||||||||||

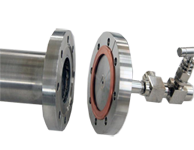

Sealing of flange |

| 1.CF flange structure drawing is as follows (using copper sealing ring) | |||||||||||

| Special stainless steel crucible |  | ||||||||||||

| Net weight | Approx. 80KG | ||||||||||||

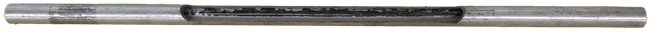

Cautions | The company's high temperature and high pressure furnace tubes are made of high temperature alloy steel, the highest temperature resistance of 1150℃, good ductility. When the air pressure inside the cavity exceeds the maximum tolerable value (exceeding the long-term strength of the alloy tube) due to misoperation, the alloy tube will creep and bulge at the weak place first, then crack will appear to release the gas. No high pressure cracking risk. | ||||||||||||

Service | 1 year warranty with lifetime support (The warranty does not include consumable parts, such as furnace tubes and sealing rings). | ||||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

MiNi tube furnace 1200℃

Bridgman crystal growth furnace

1200 ℃ CVD integrated machine

Automatic hydrogen making machine H300

Soft pack battery pressure online test kit

Vertical tube furnace (saturated steam)

Ion sputtering coating instrument

Split pit furnace for glove box

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China