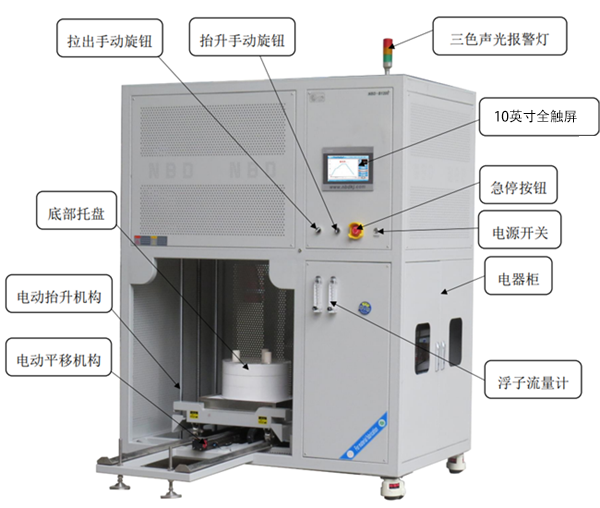

Clean-type top hat furnace

Release time: 2022-11-03 08:48:51 Number of views: 693

NPBODY top hat furnace is mainly used in high temperature sintering production of inorganic materials annealing, electronic ceramics, zirconia ceramics, alumina ceramics, dielectric ceramics, magnetic materials, nanomaterials, as well as special ceramic target products pre-firing and sintering treatment, high purity quartz, sapphire and other annealing processes.

Configuration

| 1. Reservation sintering function: the sintering time can be set according to the demand, and the pre-stored sintering process can be automatically implemented; | ||||||||||||||

Model | NBD-B1200-450T22FLW | ||||||||||||||

Main heating thermocouple model | K型 280mm*φ2 (Two detections, two controls) | ||||||||||||||

Gas preheating thermocouple model | K-type 250mm*φ1 | ||||||||||||||

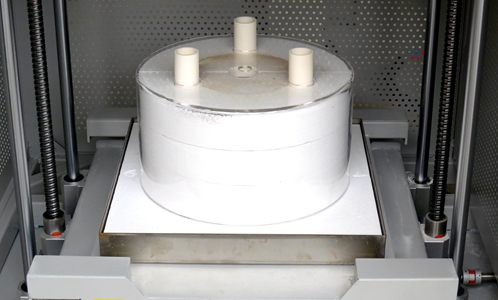

Size of heating zone | two heating zones;φ600*250mm | ||||||||||||||

Length of heating zone | 500mm | ||||||||||||||

Pallet size available | φ350*350mm | ||||||||||||||

| Automatic lifting mode | Closed-loop stepper motor drive ball screw drive speed 12.6mm/s (adjustable) | ||||||||||||||

| Automatic pull-out mode | Closed-loop stepper motor drive synchronous belt speed 40mm/s(adjustable) | ||||||||||||||

| Intake mode | Float flowmeter (with solenoid valve control can be selected to open and close along with the program segment) | ||||||||||||||

| Air intake specifications | φ6.35mm | ||||||||||||||

| Exhaust port specification | KF40 (optional exhaust gas treatment unit and induced draft fan) | ||||||||||||||

Main heating power | 24KW | ||||||||||||||

| Gas preheating power | 1.2KW | ||||||||||||||

| Rated input voltage | Three-phase 380V/50Hz | ||||||||||||||

| Rated temperature of main heating | 1150℃ (Heating method: HRE resistance wire heating) | ||||||||||||||

| Gas preheating rated temperature | 500℃ (Heating method: HRE resistance wire heating) | ||||||||||||||

| Number of heating control zones | Single temperature and dual control | ||||||||||||||

| Recommended heating rate | ≤10℃/min | ||||||||||||||

| Temp Accuracy | ≤±1℃ | ||||||||||||||

| Cooling rate controllable mode | After the temperature reaches a certain temperature point, the furnace platform can automatically drop a certain distance to improve the cooling rate | ||||||||||||||

| boundary dimension | L1580*H2050*D1150mm | ||||||||||||||

| Control system |

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; 2, can be reserved sintering, to achieve unattended sintering process curve sintering; 3, real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless recording; 4, with remote control, real-time observation of equipment status; 5, temperature correction: the difference between the main control temperature and the sample temperature, the whole sintering process for nonlinear correction. | ||||||||||||||

High purity alumina fiber stove: 2, built-in gas preheating system; 3. Automatic calibration of hearth lifting origin; 4, gas temperature output design; 5, can be preset temperature slow down rate; 6, the horizontal and vertical lifting rate can be adjusted. |

| ||||||||||||||

1, high purity quartz liner; 2, the heating element ring distribution, uniform temperature field; |

| ||||||||||||||

Temp Accuracy | +/- 1 ℃ | ||||||||||||||

gas supply system |

| The furnace body reserves two float flowmeter air intake, which is controlled by the electric control system and solenoid valve, and enters the gas preheater after three-way merger, and then enters the reaction. The reaction gas is discharged through the top exhaust port in the chamber. | |||||||||||||

| Net weight | Approx.854KG | ||||||||||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable parts, such as quartz products and seals). | ||||||||||||||

Disclaimer:

The content of product introduction (including product pictures, product descriptions, technical parameters, etc.) is for reference only. Due to the delay in updating, there may be some differences between the said content and the actual situation. Please contact our customer service staff for confirmation. The information provided on this site does not constitute any offer or commitment, and Nobadi will improve and modify any information on this site from time to time without prior notice.

推荐产品

Vertical tube furnace (Type II)

Universal testing machine with heating furnace (Type B)

Double temperature rapid annealing slide furnace

Openable vertical tube furnace 1200℃

Ion sputtering coating instrument

Vertical tube furnace (saturated steam)

Split type mini tube furnace

Bottom-loading sintering furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China