Ultra-high temp. vacuum atmosphere sintering furnace

Release time: 2022-11-02 12:23:22 Number of views: 889

The high vacuum atmosphere tungsten wire furnace is a vertical vacuum resistance furnace using high purity tungsten wire as heating element, which is mainly used for sintering or annealing of metal compounds, ceramics and inorganic compounds in vacuum or protective atmosphere. It can also be used for heat treatment of metal materials.

The electric furnace is of cycle operation type and bottom inlet and outlet structure.

The electric furnace is of cycle operation type and bottom inlet and outlet structure.

Configuration

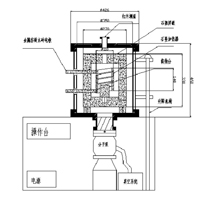

Structure description: 1, the furnace body is a vertical shell, using double water sandwich structure, the upper and lower flanges are welded into a cylindrical structure. The inner and outer walls are stainless steel (304) sandblasting treatment, and the flange plane is provided with a sealing groove. The "O" ring vacuum seal, in order to prevent the "O" ring aging due to high temperature, are equipped with water cooling device, the side of the furnace body is provided with suction holes, electrode extraction holes, observation holes, temperature measuring holes, etc. 2, heating element: the use of energy-saving tungsten mesh structure, it is connected with the electrode, and by the furnace control system three-phase power supply after transformer step-down with bronze connected to three leading electrodes, forming a control loop, less power consumption, novel structure. 3, heat insulation screen: the heat insulation screen around the furnace, the top and the bottom are made of two layers of tungsten sheet, eight layers of molybdenum sheet and a layer of 304 stainless steel bracket, which are processed into an overall heat insulation system. 4, the furnace cover: the double-layer water sandwich structure, the inner and outer walls are stainless steel sandblasting treatment, welded with the flange, the center of the furnace cover is equipped with temperature control hole. 5, the furnace frame box: by the section steel and steel plate group welded into a box-type frame structure, the furnace body is placed on the furnace frame. 6, water cooling system: by a variety of valves, pipelines and other related devices, with water, sound and light alarm and automatic cut off the heating power supply function. 7. Vacuum system: Using a TRP-60 direct connection mechanical pump (advantages of small pollution vibration) no oil, novel structure, a molecular pump, vacuum unit, vacuum filter, air discharge valve (manual and pneumatic), pneumatic high vacuum flapper valve, pneumatic disc valve, vacuum pressure gauge (±Pa), vacuum pipe and pump using metal corrugated hose, quick joint connection, The vacuum measuring instrument is a composite digital high vacuum measuring instrument, which has a wide measuring range and can realize the whole process of continuous vacuum measurement. 8, control system: with multiple groups of P.I.D function automatic control, with over temperature sound and light alarm function, electric control system also has over current, water, over temperature sound and light alarm function. The main electrical components are Omron or Schneider brand, the electrical control system is concentrated in the control cabinet, and the panel is designed with a 10-inch LCD touch screen, current and voltmeter, vacuum gauge, etc. The control cabinet is a standard electric control cabinet structure with integrated ventilation system. It can ensure that the normal use of components and instruments in the cabinet will not be affected because the ambient temperature is too high. All operating conditions are equipped with safety interlock protection, with overtemperature power off, water power off (stop heating, vacuum pump, etc.). Set up the necessary sound and light alarm and protection, such as overtemperature, low water pressure, low air pressure, set up an emergency switch. | |||||||||

Model | NBD-B2200-160TIGF | ||||||||

Electrical Spec | AC380V three-phase 50HZ | ||||||||

Rated power | 45 Kw ±10 Kw | ||||||||

Tmax | 2000℃ | ||||||||

| Number of temp. control zones | 1 | ||||||||

| Work area size | Φ 160×160 mm | ||||||||

| Cold limit vacuum | 5×10-4Pa | ||||||||

| Rate of pressure rise | 3.0 Pa/h | ||||||||

temp control range | RT ~2000 ℃ (tungsten-rhenium thermocouple) | ||||||||

| Temp Accuracy | ≤ ±1℃ | ||||||||

| plenum pressure | ≤0.015 MPa | ||||||||

| Gas-filled medium | Argon/nitrogen | ||||||||

operating control | touch screen&PLC | ||||||||

Control system |

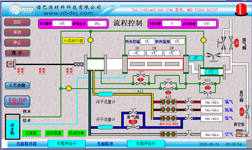

| The control part takes 10-inch touch screen and programmable controller PLC as the core, equipped with air switch, contactor, relay, indicator light and other components, and realizes the logical control of the mechanical mechanism of the furnace through the signals of various sensors. Record, store, display in real time and set the process curve for temperature and vacuum degree, and have the function of storing and calling multiple groups of process formulas. | |||||||

Temp Accuracy | +/- 1℃ | ||||||||

Heating element |

|

| |||||||

Energy saving tungsten mesh structure | |||||||||

Cautions | 1, always pay attention to the temperature of the furnace cover, furnace body, furnace bottom and water-cooled electrode, can not be hot, otherwise to stop heating, check whether the water is smooth. 2, if the vacuum degree is not pumped, it should be checked whether the oil in the diffusion pump is oxidized, and whether the mechanical pump is aging, such as aging should be replaced in time. 3, when filling protective gas, attention should be paid to the value of the vacuum pressure gauge, which can not exceed the positive pressure (generally 2-3 cells below 0 and about -50Pa, the furnace is still negative pressure). It should be noted that the gas has the characteristics of thermal expansion, if close to the positive pressure, you can open the mechanical pump and pre-extraction valve to remove part of the gas. 4, when loading, be sure not to touch the graphite heating body (saw seam), because the heating body is fragile after burning, causing unnecessary losses. 5, usually should pay attention to the furnace, outside the furnace cleaning, vacuum valve maintenance work. 6, after opening the pump, pay attention to check whether each valve is fully opened, and the connected water pipe is not dripping, if any, it should be eliminated in time. | ||||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable components such as furnace tubes and seals). | ||||||||

Configuration

Structure description: 1, the furnace body is a vertical shell, using double water sandwich structure, the upper and lower flanges are welded into a cylindrical structure. The inner and outer walls are stainless steel (304) sandblasting treatment, and the flange plane is provided with a sealing groove. The "O" ring vacuum seal, in order to prevent the "O" ring aging due to high temperature, are equipped with water cooling device, the side of the furnace body is provided with suction holes, electrode extraction holes, observation holes, temperature measuring holes, etc. 2, heating element: the use of energy-saving tungsten mesh structure, it is connected with the electrode, and by the furnace control system three-phase power supply after transformer step-down with bronze connected to three leading electrodes, forming a control loop, less power consumption, novel structure. 3, heat insulation screen: the heat insulation screen around the furnace, the top and the bottom are made of two layers of tungsten sheet, eight layers of molybdenum sheet and a layer of 304 stainless steel bracket, which are processed into an overall heat insulation system. 4, the furnace cover: the double-layer water sandwich structure, the inner and outer walls are stainless steel sandblasting treatment, welded with the flange, the center of the furnace cover is equipped with temperature control hole. 5, the furnace frame box: by the section steel and steel plate group welded into a box-type frame structure, the furnace body is placed on the furnace frame. 6, water cooling system: by a variety of valves, pipelines and other related devices, with water, sound and light alarm and automatic cut off the heating power supply function. 7. Vacuum system: Using a TRP-60 direct connection mechanical pump (advantages of small pollution vibration) no oil, novel structure, a molecular pump, vacuum unit, vacuum filter, air discharge valve (manual and pneumatic), pneumatic high vacuum flapper valve, pneumatic disc valve, vacuum pressure gauge (±Pa), vacuum pipe and pump using metal corrugated hose, quick joint connection, The vacuum measuring instrument is a composite digital high vacuum measuring instrument, which has a wide measuring range and can realize the whole process of continuous vacuum measurement. 8, control system: with multiple groups of P.I.D function automatic control, with over temperature sound and light alarm function, electric control system also has over current, water, over temperature sound and light alarm function. The main electrical components are Omron or Schneider brand, the electrical control system is concentrated in the control cabinet, and the panel is designed with a 10-inch LCD touch screen, current and voltmeter, vacuum gauge, etc. The control cabinet is a standard electric control cabinet structure with integrated ventilation system. It can ensure that the normal use of components and instruments in the cabinet will not be affected because the ambient temperature is too high. All operating conditions are equipped with safety interlock protection, with overtemperature power off, water power off (stop heating, vacuum pump, etc.). Set up the necessary sound and light alarm and protection, such as overtemperature, low water pressure, low air pressure, set up an emergency switch. | |||||||||

Model | NBD-B2200-160TIGF | ||||||||

Electrical Spec | AC380V three-phase 50HZ | ||||||||

Rated power | 45 Kw ±10 Kw | ||||||||

Tmax | 2000℃ | ||||||||

| Number of temp. control zones | 1 | ||||||||

| Work area size | Φ 160×160 mm | ||||||||

| Cold limit vacuum | 5×10-4Pa | ||||||||

| Rate of pressure rise | 3.0 Pa/h | ||||||||

temp control range | RT ~2000 ℃ (tungsten-rhenium thermocouple) | ||||||||

| Temp Accuracy | ≤ ±1 ℃ | ||||||||

| plenum pressure | ≤ 0.015 MPa | ||||||||

| Gas-filled medium | Argon/nitrogen | ||||||||

operating control | touch screen&PLC | ||||||||

Control system |

| The control part takes 10-inch touch screen and programmable controller PLC as the core, equipped with air switch, contactor, relay, indicator light and other components, and realizes the logical control of the mechanical mechanism of the furnace through the signals of various sensors. Record, store, display in real time and set the process curve for temperature and vacuum degree, and have the function of storing and calling multiple groups of process formulas. | |||||||

Temp Accuracy | +/- 1℃ | ||||||||

Heating element |

|

| |||||||

Energy saving tungsten mesh structure | |||||||||

Cautions | 1, always pay attention to the temperature of the furnace cover, furnace body, furnace bottom and water-cooled electrode, can not be hot, otherwise to stop heating, check whether the water is smooth. 2, if the vacuum degree is not pumped, it should be checked whether the oil in the diffusion pump is oxidized, and whether the mechanical pump is aging, such as aging should be replaced in time. 3, when filling protective gas, attention should be paid to the value of the vacuum pressure gauge, which can not exceed the positive pressure (generally 2-3 cells below 0 and about -50Pa, the furnace is still negative pressure). It should be noted that the gas has the characteristics of thermal expansion, if close to the positive pressure, you can open the mechanical pump and pre-extraction valve to remove part of the gas. 4, when loading, be sure not to touch the graphite heating body (saw seam), because the heating body is fragile after burning, causing unnecessary losses. 5, usually should pay attention to the furnace, outside the furnace cleaning, vacuum valve maintenance work. 6, after opening the pump, pay attention to check whether each valve is fully opened, and the connected water pipe is not dripping, if any, it should be eliminated in time. | ||||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable components such as furnace tubes and seals). | ||||||||

Related products

|

| ||

推荐产品

Medium frequency induction alloy sublimation furnace

Ultra high pressure and high temperature sintering furnace

Experimental hydrogen reduction furnace

Meltblowout cloth nozzle anaerobic cleaning furnace 1200℃

Large high temperature vacuum atmosphere muffle furnace

0.35L melting furnace 1600℃

Industrial rotary pendulum sintering furnace

Uniform temperature heating platform

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China