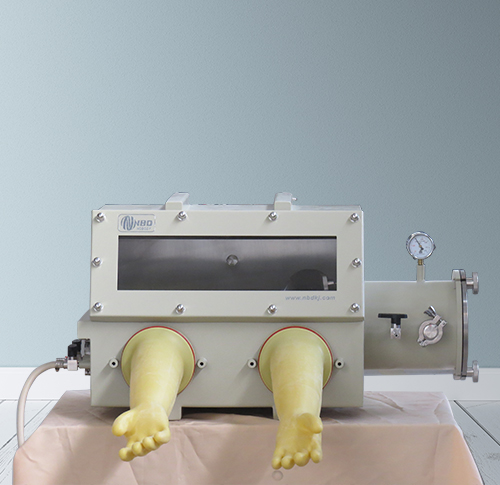

Desktop type Glove box

Release time: 2022-10-19 15:23:51 Number of views: 782

In chemical reactions and the treatment of test samples, some substances are very sensitive to oxygen and water and cannot be carried out in the ordinary natural environment.

Although the chemical reactions of such substances can be carried out in vacuum containers, they cannot be operated, which makes the chemical reactions of such substances and the processing of samples very difficult. The use of a vacuum glove box enables the material to operate, react and test freely in the inert gas environment which is relatively free of oxygen and water. Therefore, it is widely used in chemistry, chemical engineering, biology, biochemistry and battery, especially in the preparation and research of some catalysts and metallic organics (such as MO source, etc.). For example, the planetary ball mill produced by our factory is easy to oxidize and delix, or even burn, when the ground material is ground in the vacuum tank and sampled in the atmospheric environment. In this product, the grinding sample can be safely removed and put in.

| Equipment introduction: | ||

Glove box + series products

|

| |

| Equipment features: The system is made of stainless steel, corrosion resistance, easy to clean, no pollution, operating box facing the window, wide Angle of view, the box is equipped with a number of valves, easy to use. The box is equipped with a porous electric socket, which can provide power for various instruments and carry out scientific experiments; Operating gloves use thick latex gloves for reliable sealing. The sealing device of the front chamber and the main box is novel in design, reliable in sealing and convenient in opening. | |

Main technical performance: | ||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

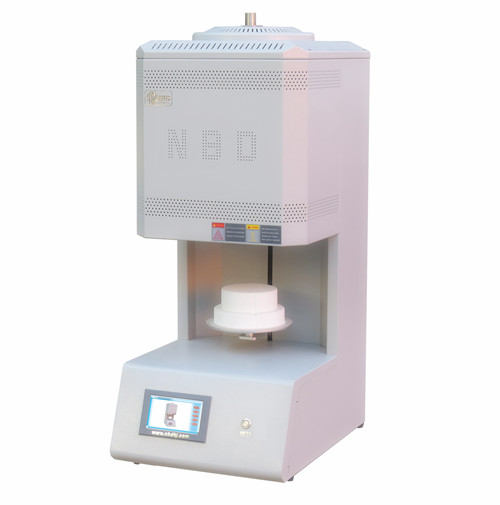

Open-sided industrial sintering furnace

Large capacity bottom-loading furnace

Vertical high-temperature tube furnace (Type I)

Mini hydrogen reduction furnace

Liquid-gas CVD all-in-one machine

Roll to roll two-dimensional material preparation system

Clean-type top hat furnace

Vacuum molten salt electrolysis furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China