Production type swing rotary converter

Release time: 2022-09-29 15:26:41 Number of views: 907

Equipment introduction:

This equipment is 310S stainless steel inner cylinder external thermal rotary resistance furnace, which can be used for lithium battery and other anode materials, five strong acid and alkaline powder and other particle like materials in the laboratory pilot test stage of calcination and drying, users can according to the material firing process for the corresponding atmosphere protection. Production mode for intermittent production, can be calcined powder materials.

| 设备简介 | 1. This equipment mainly consists of several parts such as furnace body, lifting system, mechanical transmission system, intake and exhaust system, etc;

| |||

Electrical specifications | NBD-RT1200-325T33D2F | |||

| Thermocouple model | K型 450mm | |||

| Effective working area size of furnace tube | φ309~L1250mm | |||

| Furnace tube wall thickness | 8mm | |||

| Furnace tube material | 310S stainless steel | |||

| Whole machine power | 21KW | |||

| Main transmission power | 0.12KW | |||

| Electric push rod power | 0.25KW | |||

| Rated input voltage | 三相380V/50Hz | |||

| Usage temperature | 30~1100℃ | |||

| Temperature control in the temperature zone | Single temperature three control | |||

| Temp Accuracy | ≤±1℃ | |||

| Temperature control method | Digital Touch PID Control | |||

| Tilting angle of furnace | -Adjustable from 5 to 15 degrees | |||

| Furnace tube speed | 1~3 revolutions per minute adjustable | |||

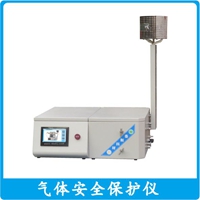

| gas control | Two way mass flow meter intake (2MFC) | |||

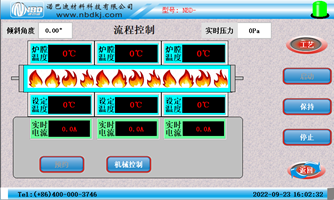

operating system |

1. Sintering process curve setting: Dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; | |||

Partial interface |

|

| ||

Service Support | One year limited warranty, providing lifelong support; | |||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

Related products

| |||

|

|

|

推荐产品

Manual button battery sealing machine

well-type crucible melting furnace 0.1L 1200℃

Meltblowout cloth nozzle anaerobic cleaning furnace 1200℃

Automatic hydrogen making machine H1000

0.35L melting furnace 1600℃

Cold wall intermediate frequency induction melting furnace

Vertical eight channel high-throughput tube furnace

Industrial tubular furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China