Mesh belt brazing furnace

Release time: 2022-09-20 15:00:33 Number of views: 1646

Configuration details

Configuration details | NBD-T1200-15WQHLNH6600Mesh belt brazing furnace is mainly composed of furnace body, transmission system, temperature control system, atmosphere control system and inlet platform and frame system。The total length of the equipment is 7225mm, of which the furnace body is 2110mm。The kiln adopts open design outside the furnace body, tunnel type structure, the furnace adopts SUS310S Muffle tube structure。

| ||||||

Working principle of mesh belt brazing furnace | The workpiece is driven by a stainless steel mesh belt,The work piece is placed on the mesh belt,Enter from the inlet of the preheating section,It's transmitted over the webbing,After preheating, heating (solder melting), cooling。The workpiece of discharge in the cooling section will always be protected by pure hydrogen gas,由Due to the reducibility of hydrogen, the surface of the product is bright and non-oxidized。Workpiece welding is to melt the filling material (filler metal) by heating the workpiece, and use the capillary action to fill the gap between the liquid filler metal and the base metal. After cooling, the welding purpose is achieved。 | ||||||

model number | NBD-T1200-15WQHLNH6600 | ||||||

950℃ | |||||||

Webbing width | 150mm | ||||||

Furnace height | 60mm | ||||||

Temperature control zone | 3 temperature zones, independent control | ||||||

Temperature control number | Three o 'clock | ||||||

Control thermocouple | K scale thermocouple | ||||||

| temperature control accuracy | ±1℃ | ||||||

| heating up time | ≤4h(900℃) | ||||||

±5℃(Constant temperature zone) | |||||||

| Temperature control instrument table | Single circuit imported intelligent multi-stage temperature controller, PID parameters self-tuning | ||||||

| Heating mode | High temperature alloy wire is wrapped around ceramic heating rod | ||||||

Furnace tube | Large furnace cavity structure and 8MM thick SUS310S heat-resistant steel tube structure imported from Japan | ||||||

Transmission system | Adopt imported motor, the whole tensioning drive, with tensioning adjustment device | ||||||

| Band speed range | 20 ~ 170mm/min; The usual speed is 100mm/min | ||||||

| Mesh tape material | High temperature resistant nickel-chromium alloy | ||||||

| Thermal insulation material | Alumina ceramic fiber products | ||||||

| Atmosphere system | Nitrogen or nitrogen-hydrogen | ||||||

| Exhaust system | One exhaust chimney is provided for each inlet and outlet | ||||||

| Surface temperature rise | ≤40℃ | ||||||

| Oxygen content detection | Equipped with oxygen content and dew point detection probe | ||||||

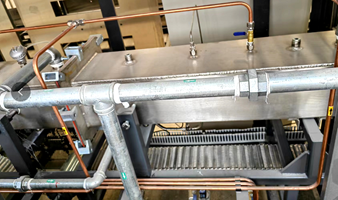

| Cooling system | Stainless steel water-cooled jacket | ||||||

| Optional function | Protective atmosphere system; Embedded computer control system, atmosphere detection and analysis system; Circulation logistics system, equipment purification application. | ||||||

| Cooling system structure outline |

| ||||||

Operating panel |   | ||||||

Service support | One year limited warranty with lifetime support (The warranty does not cover consumable parts such as furnace tubes and seals) | ||||||

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

Configuration details

Configuration details | NBD-T1200-15WQHLNH6600Mesh belt brazing furnace is mainly composed of furnace body, transmission system, temperature control system, atmosphere control system and inlet platform and frame system。The total length of the equipment is 7225mm, of which the furnace body is 2110mm。The kiln adopts open design outside the furnace body, tunnel type structure, the furnace adopts SUS310S Muffle tube structure。

| ||||||

Working principle of mesh belt brazing furnace | The workpiece is driven by a stainless steel mesh belt,The work piece is placed on the mesh belt,Enter from the inlet of the preheating section,It's transmitted over the webbing,After preheating, heating (solder melting), cooling。The workpiece of discharge in the cooling section will always be protected by pure hydrogen gas,由Due to the reducibility of hydrogen, the surface of the product is bright and non-oxidized。Workpiece welding is to melt the filling material (filler metal) by heating the workpiece, and use the capillary action to fill the gap between the liquid filler metal and the base metal. After cooling, the welding purpose is achieved。 | ||||||

model number | NBD-T1200-15WQHLNH6600 | ||||||

950℃ | |||||||

Webbing width | 150mm | ||||||

Furnace height | 60mm | ||||||

Temperature control zone | 3 temperature zones, independent control | ||||||

Temperature control number | Three o 'clock | ||||||

Control thermocouple | K scale thermocouple | ||||||

| temperature control accuracy | ±1℃ | ||||||

| heating up time | ≤4h(900℃) | ||||||

±5℃(Constant temperature zone) | |||||||

| Temperature control instrument table | Single circuit imported intelligent multi-stage temperature controller, PID parameters self-tuning | ||||||

| Heating mode | High temperature alloy wire is wrapped around ceramic heating rod | ||||||

Furnace tube | Large furnace cavity structure and 8MM thick SUS310S heat-resistant steel tube structure imported from Japan | ||||||

Transmission system | Adopt imported motor, the whole tensioning drive, with tensioning adjustment device | ||||||

| Band speed range | 20 ~ 170mm/min; The usual speed is 100mm/min | ||||||

| Mesh tape material | High temperature resistant nickel-chromium alloy | ||||||

| Thermal insulation material | Alumina ceramic fiber products | ||||||

| Atmosphere system | Nitrogen or nitrogen-hydrogen | ||||||

| Exhaust system | One exhaust chimney is provided for each inlet and outlet | ||||||

| Surface temperature rise | ≤40℃ | ||||||

| Oxygen content detection | Equipped with oxygen content and dew point detection probe | ||||||

| Cooling system | Stainless steel water-cooled jacket | ||||||

| Optional function | Protective atmosphere system; Embedded computer control system, atmosphere detection and analysis system; Circulation logistics system, equipment purification application. | ||||||

| Cooling system structure outline |

| ||||||

Operating panel |   | ||||||

Service support | One year limited warranty with lifetime support (The warranty does not cover consumable parts such as furnace tubes and seals) | ||||||

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

推荐产品

Vertical tube furnace (Type II)

Hydrogen reduction integrated sintering furnace (1500 ℃)

Industrial vertical kiln

well-type crucible melting furnace 0.1L 1200℃

Sliding rail mobile fast annealing furnace

Vacuum graphite heating furnace

Plasma enhanced rotary PECVD system

Rotary pendulum oxidation furnace (silicon nitride tube)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China