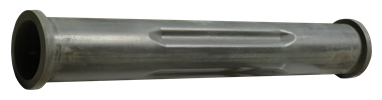

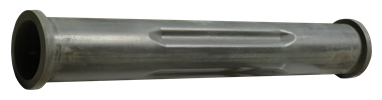

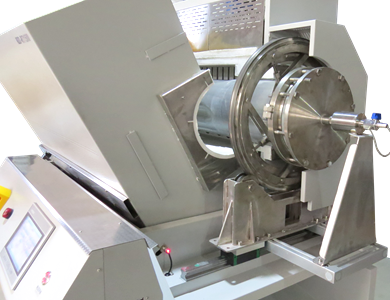

Rotary pendulum oxidation furnace (silicon nitride tube)

Release time: 2022-09-07 11:28:03 Number of views: 894

Equipment introduction:

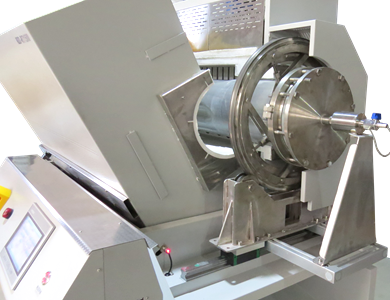

This device provides sintering environment in vacuum or atmosphere environment, all operations are completed on the touch screen, convenient for customers to operate. This equipment is a high temperature rotary furnace, the furnace tube is made of new silicon nitride combined with silicon carbide products, has excellent oxidation resistance, good wear resistance and corrosion resistance to metal solution, is a new type of structural ceramic material, for the sintering of high temperature materials to provide a stable environment, in order to ensure the safe operation of the equipment.

Configuration

| 1. The furnace tube is made of new silicon nitride combined with silicon carbide products, which has excellent oxidation resistance, good wear resistance and corrosion resistance to metal solution; 2. Adopt PLC centralized control, simplify operation, configure 7 inch touch screen all kinds of data real-time display, intuitive and clear; 3. Set alarm function, can realize unattended sintering; 4. The furnace can be opened automatically by the control system, which is convenient for the maintenance of the furnace tube and heating system; 5. High purity Al2O3 fiber refractory insulation material, insulation effect is superior, effectively reduce the power consumption of equipment; 6. Adopt advanced and stable dynamic sealing system to ensure that the equipment can be used in vacuum and atmosphere. | ||||||

Model | NBD-RT1500-200TII | ||||||

Electrical Spec | 3-phase ~380V 50HZ;18 KW | ||||||

Tmax | 1450℃ | ||||||

Temp Accuracy | ±1℃ | ||||||

Thermocouple type | Type S thermocouple 170mm | ||||||

Heating length | 640mm | ||||||

| Tube size | φ200*φ180*1400mm | ||||||

Furnace dimension | L1760×D1120×H1665mm | ||||||

| Lifting inclination Angle | -6 degrees-15 degrees | ||||||

| Angle of oscillation | ±3 degrees | ||||||

| Rotational speed | 3-7 R/min | ||||||

| Total rotation reduction ratio | 1:96(sprocket wheel 1:4) | ||||||

| Maximum Angle of opening cover | 30 degrees | ||||||

| Size of inlet and outlet gas joints | Air inlet φ6.35 card sleeve, air outlet φ12 pagoda | ||||||

| Heating rate | ≤10℃/min | ||||||

Silicon nitride, silicon carbide composite material furnace tube |  | ||||||

Control system |

| 1. Sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |||||

Mechanical control interface |  | ||||||

Temp Accuracy | +/- 1 ℃ | ||||||

Heating element | High purity silicon molybdenum rod | ||||||

PLC automatic control furnace opening |  | ||||||

Net weight | ≈650KG | ||||||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | ||||||

Service | 1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). | ||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

| |||

Configuration

| 1. The furnace tube is made of new silicon nitride combined with silicon carbide products, which has excellent oxidation resistance, good wear resistance and corrosion resistance to metal solution; 2. Adopt PLC centralized control, simplify operation, configure 7 inch touch screen all kinds of data real-time display, intuitive and clear; 3. Set alarm function, can realize unattended sintering; 4. The furnace can be opened automatically by the control system, which is convenient for the maintenance of the furnace tube and heating system; 5. High purity Al2O3 fiber refractory insulation material, insulation effect is superior, effectively reduce the power consumption of equipment; 6. Adopt advanced and stable dynamic sealing system to ensure that the equipment can be used in vacuum and atmosphere. | ||||||

Model | NBD-RT1500-200TII | ||||||

Electrical Spec | 3-phase ~380V 50HZ;18 KW | ||||||

Tmax | 1450℃ | ||||||

Temp Accuracy | ±1℃ | ||||||

Thermocouple type | Type S thermocouple 170mm | ||||||

Heating length | 640mm | ||||||

| Tube size | φ200*φ180*1400mm | ||||||

Furnace dimension | L1760×D1120×H1665mm | ||||||

| Lifting inclination Angle | -6 degrees-15 degrees | ||||||

| Angle of oscillation | ±3 degrees | ||||||

| Rotational speed | 3-7 R/min | ||||||

| Total rotation reduction ratio | 1:96(sprocket wheel 1:4) | ||||||

| Maximum Angle of opening cover | 30 degrees | ||||||

| Size of inlet and outlet gas joints | Air inlet φ6.35 card sleeve, air outlet φ12 pagoda | ||||||

| Heating rate | ≤10℃/min | ||||||

Silicon nitride, silicon carbide composite material furnace tube |  | ||||||

Control system |

| 1. Sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |||||

Mechanical control interface |  | ||||||

Temp Accuracy | +/- 1 ℃ | ||||||

Heating element | High purity silicon molybdenum rod | ||||||

PLC automatic control furnace opening |  | ||||||

Net weight | ≈650KG | ||||||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | ||||||

Service | 1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). | ||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

| |||

推荐产品

Dual-channel K-type digital thermometer

High vacuum atmosphere muffle furnace

Microwave muffle furnace

Openable vertical tube furnace 1200℃

Plasma enhanced rotary PECVD system

Extended tube furnace with single temperature zone 1500℃

Blast drying oven (galvanized)

Thermogravimetric analysis (TGA) and condensation collection systems

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China