Vertical homogenizing melting furnace

Release time: 2022-08-29 10:49:08 Number of views: 986

Equipment introduction:

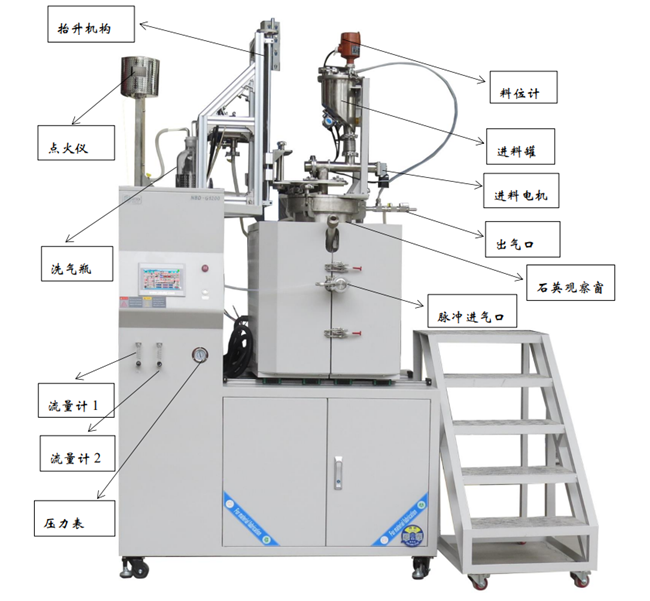

The equipment is equipped with an automatic feeding system, the material is melted in vacuum, inert gas protection or reaction gas environment, and the sealing rotary hoist completes the automatic feeding, melting, chemical reaction and homogenization of the material under the pulse gas coordination. Meanwhile, the high purity quartz observation window can observe the material status in real time.

7 inch full touch screen intelligent human-machine interaction system, the operation process is convenient and intuitive, equipped with flammable exhaust automatic ignition system, can ensure the safety and stability of the entire process.

Configuration

| 1. The collection device is equipped with a double-layer water cooling system, which can greatly improve the cooling collection efficiency of materials

| ||||||||||||||

Model | NBD-G1200-26TI2F-350 | ||||||||||||||

Electrical Spec. | Three-phase 380V 50HZ | ||||||||||||||

Tmax |

1150℃ | ||||||||||||||

rated power | 12KW | ||||||||||||||

thermocouple | Type K thermocouple 420mm | ||||||||||||||

heating-zone size | φ350*420mm | ||||||||||||||

| Furnace tube material | 310s stainless steel pipe | ||||||||||||||

| Effective volume of furnace tube | 70L | ||||||||||||||

| Mixing motor speed | 0~11R/min | ||||||||||||||

| Blanking motor speed | 0~19R/min | ||||||||||||||

| Furnace size | L1430×D1060×H2560mm | ||||||||||||||

Recommended heating rate | 10℃/min | ||||||||||||||

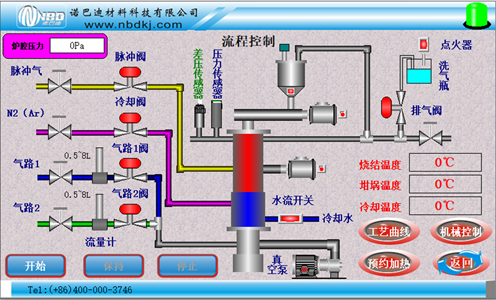

Main control interface |

| ||||||||||||||

| Control system |

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | ||||||||||||||

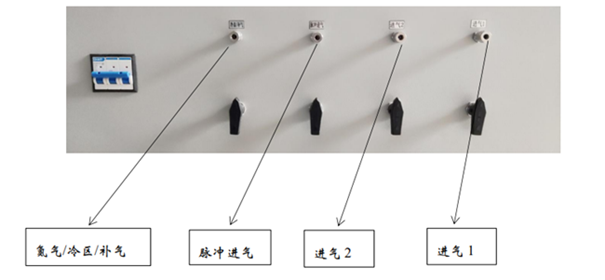

| gas control system |

| ||||||||||||||

Temp. Accuracy | +/- 1 ℃ | ||||||||||||||

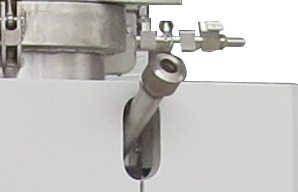

High definition working chamber quartz viewing window |

| ||||||||||||||

Pressure measurement and monitoring |

| The mechanical pressure gauge with damping oil is used to make the pressure fluctuation produce damping and reduce the pointer swinging back and forth. | |||||||||||||

gas supply system |

| The float flowmeter is used to control the gas flow rate, which is integrated with the equipment, and the leakage test has been carried out before the factory. | |||||||||||||

| weight | Approx.650KG | ||||||||||||||

Cautions | 1. When the equipment is used, the absolute pressure gauge reading should not be greater than 0.15MPa to prevent equipment damage caused by excessive pressure;

| ||||||||||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable parts such as furnace tubes and seals) | ||||||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

| |||

推荐产品

Pressure rotary tube furnace

Oscillating ball mill mixer

Expansion coefficient tester

Melting furnace 1500/1700℃

Vertical quenching furnace

Clean-type top hat furnace

(non) metal evaporation purification system

Industrial vertical kiln

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China