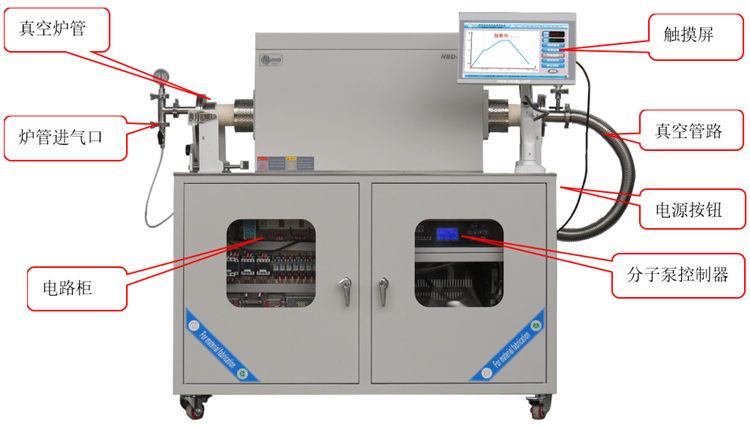

High temperature and high vacuum CVD all-in-one machine

Release time: 2022-8-16 9:13:57 Number of views: 1001

|

|

Equipment introduction:

|

||

|

|

|

|

|

|

|

|

|

|

Configuration:

|

|

The equipment adopts a 15.6-inch full-touch intelligent human-computer interaction system, a high-vacuum molecular pump set, a new generation of oil-free scroll vacuum pump as the front pump, and a high-precision gas mass flow control system to realize intelligent sample operation under high-precision gas control and high temperature (Tmax: 1650℃). |

||||||||

|

Model |

NBD-CVD1700-T22G3Z |

||||||||

|

Tmax |

1700℃ |

||||||||

|

Max working temps |

1650℃ |

||||||||

|

Temp Accuracy |

±1℃ |

||||||||

|

Touch screen size |

15.6 inches |

||||||||

| rated power | 10KW | ||||||||

|

Thermocouple type |

B type |

||||||||

|

Recommended heating rate |

≤10/min |

||||||||

|

Tube size |

Ø80*1200mm |

||||||||

|

ultimate vacuum |

6X10-4Pa |

||||||||

|

Furnace dimensions |

L1690×H1410×D765mm |

||||||||

|

Oil-free scroll dry vacuum pump (front pump, with simple structure, good sealing performance, high limit vacuum advantages. In the application, it has the characteristics of low operating cost, long working life, high reliability, low noise, and has incomparable advantages in the field of oil-free cleaning. |

|

||||||||

|

Control system

|

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; |

||||||||

|

Gas system (optional) |

Type of flowmeter |

float flowmeter |

|||||||

|

Pipeline diagram |

|

|

|||||||

|

Number of inlet ports |

2, 3, 4 (multiple optional) |

||||||||

|

20-200/60-600l/min(Multi-range option) |

50/100/200sccm(Multi-range option) |

||||||||

|

Range of working pressure difference |

0-0.15MPa |

||||||||

|

Low vacuum system (optional) |

Vacuum pump type |

NBD-1.5C |

NBD-3C |

NBD-4C |

|||||

|

pumping rate |

1L/s |

3L/s |

4L/s |

||||||

|

Inlet and exhaust port dimensions |

Φ8mm Pagoda-Shape Connector |

Φ8mm Pagoda-Shape Connector |

KF16/25 |

||||||

|

ultimate pressure |

1000Pa |

100Pa |

10Pa |

||||||

|

operating temperature |

5-40℃ |

||||||||

|

Electrical Spec |

AC 220V |

||||||||

|

Molecular pump high vacuum system

|

Molecular pump system model |

NBD-103(A) |

NBD-103(B) |

NBD-103(C) |

|||||

|

pumping rate |

110L/s |

600L/s |

700L/s |

||||||

|

Vacuum gauge |

Composite vacuum gauge |

||||||||

|

ultimate pressure |

10^-3Pa |

10^-4Pa |

10^-5Pa |

||||||

|

operating temperature |

5-40℃ |

||||||||

|

Electrical Spec |

AC 220V |

AC 220V |

AC 380V |

||||||

|

* Support non - calibration, more models, welcome to call 400-000-3746 |

|||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

|

|

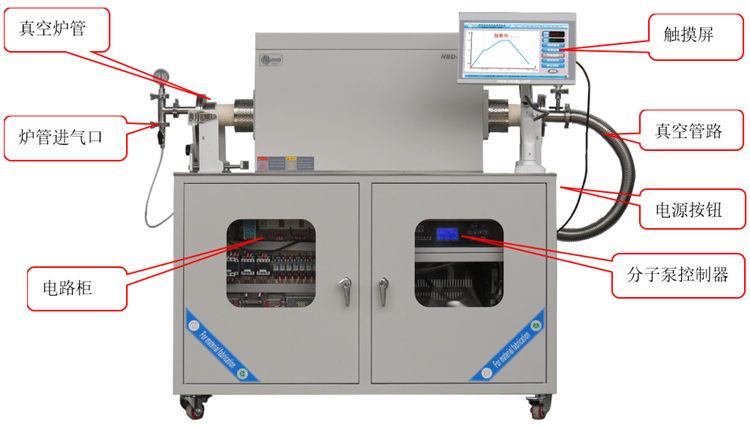

Equipment introduction:

|

||

|

|

|

|

|

|

|

|

|

|

Configuration:

|

|

The equipment adopts a 15.6-inch full-touch intelligent human-computer interaction system, a high-vacuum molecular pump set, a new generation of oil-free scroll vacuum pump as the front pump, and a high-precision gas mass flow control system to realize intelligent sample operation under high-precision gas control and high temperature (Tmax: 1650℃). |

||||||||

|

Model |

NBD-CVD1700-T22G3Z |

||||||||

|

Tmax |

1700℃ |

||||||||

|

Max working temps |

1650℃ |

||||||||

|

Temp Accuracy |

±1℃ |

||||||||

|

Touch screen size |

15.6 inches |

||||||||

| rated power | 10KW | ||||||||

|

Thermocouple type |

B type |

||||||||

|

Recommended heating rate |

≤10/min |

||||||||

|

Tube size |

Ø80*1200mm |

||||||||

|

ultimate vacuum |

6X10-4Pa |

||||||||

|

Furnace dimensions |

L1690×H1410×D765mm |

||||||||

|

Oil-free scroll dry vacuum pump (front pump, with simple structure, good sealing performance, high limit vacuum advantages. In the application, it has the characteristics of low operating cost, long working life, high reliability, low noise, and has incomparable advantages in the field of oil-free cleaning. |

|

||||||||

|

Control system

|

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; |

||||||||

|

Gas system (optional) |

Type of flowmeter |

float flowmeter |

|||||||

|

Pipeline diagram |

|

|

|||||||

|

Number of inlet ports |

2, 3, 4 (multiple optional) |

||||||||

|

20-200/60-600l/min(Multi-range option) |

50/100/200sccm(Multi-range option) |

||||||||

|

Range of working pressure difference |

0-0.15MPa |

||||||||

|

Low vacuum system (optional) |

Vacuum pump type |

NBD-1.5C |

NBD-3C |

NBD-4C |

|||||

|

pumping rate |

1L/s |

3L/s |

4L/s |

||||||

|

Inlet and exhaust port dimensions |

Φ8mm Pagoda-Shape Connector |

Φ8mm Pagoda-Shape Connector |

KF16/25 |

||||||

|

ultimate pressure |

1000Pa |

100Pa |

10Pa |

||||||

|

operating temperature |

5-40℃ |

||||||||

|

Electrical Spec |

AC 220V |

||||||||

|

Molecular pump high vacuum system

|

Molecular pump system model |

NBD-103(A) |

NBD-103(B) |

NBD-103(C) |

|||||

|

pumping rate |

110L/s |

600L/s |

700L/s |

||||||

|

Vacuum gauge |

Composite vacuum gauge |

||||||||

|

ultimate pressure |

10^-3Pa |

10^-4Pa |

10^-5Pa |

||||||

|

operating temperature |

5-40℃ |

||||||||

|

Electrical Spec |

AC 220V |

AC 220V |

AC 380V |

||||||

|

* Support non - calibration, more models, welcome to call 400-000-3746 |

|||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

ball mill tank

4C vacuum pump

Industrial vertical kiln

Full bridge crystallizing furnace

well type furnace G1200-24TI

1500℃ large capacity muffle furnace

Large denture waxing furnace

Vacuum vibrating vertical tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China