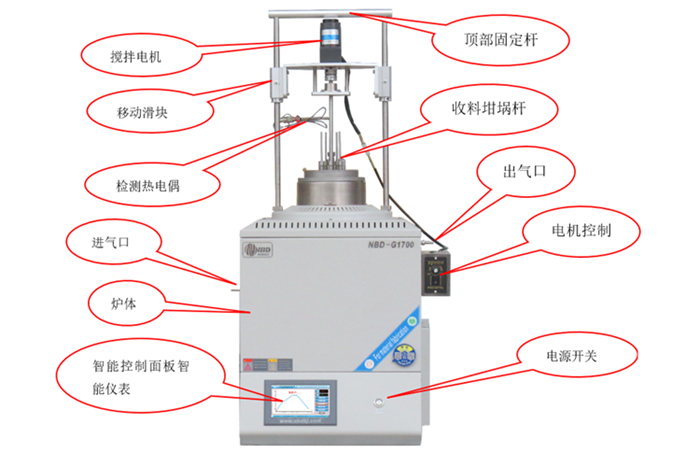

Multi-function high temperature pit furnace

Release time: 2022-07-20 14:30:21 Number of views: 990

Equipment introduction:

The equipment can be used as a conventional atmosphere pit furnace for sintering, melting and heat treatment of metal alloys, non-metallic materials and ceramic materials at high temperature under the protective atmosphere, and can also be used together with supporting components according to the test needs to meet a variety of test needs.

Configuration

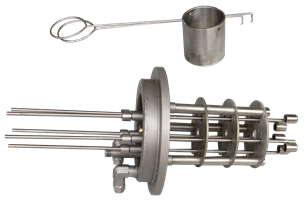

| 1. Unique air intake structure, double water cooled flange; | |||||

Equipment model | NBD-G1700-12TIN | |||||

Electrical specifications | AC220V 2.8KW | |||||

Reachable temperature | 1650℃(<1 hour) | |||||

Continuous temperature | 1600 ℃ (continuous) | |||||

| sensor type | B-type thermocouple | |||||

Recommended heating rate | ≤10℃/min | |||||

| Furnace size | φ170×160mm | |||||

External dimensions of furnace body | 570 in length, 530 in depth, and 1200mm in height | |||||

control system |

| 1. 15 temperature curves can be pre stored to avoid the trouble caused by repeated settings of different experimental processes; | ||||

precision | +/- 1℃ | |||||

Vacuum chamber crucible and sample extraction structure |

| |||||

net weight | 约80KG | |||||

Equipment usage precautions | When the equipment is burned at a temperature of 1150 ℃ -1650 ℃, the top stainless steel flange and crucible must be removed. The temperature resistance limit of stainless steel is 1150 ℃. | |||||

Service Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and seals). | |||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

Related products

推荐产品

3C vacuum pump

3 station glove box

Oscillating ball mill mixer

Open Mini Rotary Stove

Vertical tube furnace (Type II)

Graphite heater furnace

CVD系统O1200-MINI-G3Z

Medium frequency induction alloy sublimation furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China