Medium frequency induction alloy sublimation furnace

Release time: 2022-07-11 08:59:49 Number of views: 931

The equipment is composed of five systems: induction heating system, auxiliary insulation system, gas preheating system, cooling system, main control system. Induction heating adopts the industry's most advanced medium frequency induction heating power supply front uncontrollable full bridge rectifier +IGBT (Infineon) chopper control technology, its biggest advantage is no high order harmonic interference, no pollution to the grid; High power factor, high efficiency, good energy saving effect; Digital phase lock technology, high frequency stability. The control system adopts advanced PLC+ touch screen control system, with perfect protection function, making the operation more simple and convenient, and the system more stable and reliable. The control mathematical model adopts advanced PID self-learning fuzzy control to keep the temperature control accuracy at ±1℃.

Configuration

| The medium frequency induction alloy sublimation furnace includes induction melting system, auxiliary heating system and gas preheating system. The control of the three heating systems can be controlled on the touch screen of the main electric control cabinet. The induction melting system is equipped with a set of electric lifting system, which is mainly used to control the opening and closing of the material. At the same time, a pressure sensor is set to prevent the damage of the equipment caused by misoperation. The temperature measurement of induction heating adopts a two-color infrared thermometer to measure the temperature. The graphite crucible is heated by induction coil to indirectly transfer heat to achieve material melting. Therefore, it is necessary to achieve the temperature to the required temperature to wait, and then open the gas preheating, and finally open the material rod to move up, so that the melted material flows down, through the strong wind knife to disperse the material, the generated gas has a special cooling collection pipe for collection; | |||||||

Model | NBD-P1700-3L+T3D | |||||||

Electrical Spec. | Three-phase 380V; 50HZ | |||||||

Induction heating temperature measuring element type | Two-color infrared thermometer (600℃-1800℃) | |||||||

Type of auxiliary heating temperature measuring element | Type K thermocouple φ2-400mm | |||||||

rated power | Rated power: 80KW (induction heating) +36KW (auxiliary heating) +20KW (gas preheating) | |||||||

Induction heating maximum temperature | 1650℃ | |||||||

Graphite crucible dimensions | φ196*270mm | |||||||

Melting crucible volume | 3L zircon quartz crucible | |||||||

thermocouple | Type K thermocouple | |||||||

Furnace size | L1190×D1190×H2520mm | |||||||

| Furnace tube material | 310S stainless steel | |||||||

Net weight | Approx.740KG | |||||||

Recommended heating rate | 10℃/min | |||||||

Temp. Accuracy | ±1℃ | |||||||

| Control system |

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |||||||

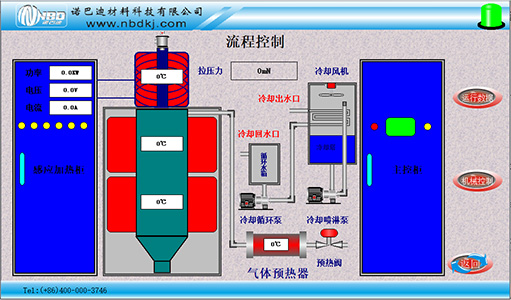

| Main monitoring interface |  | |||||||

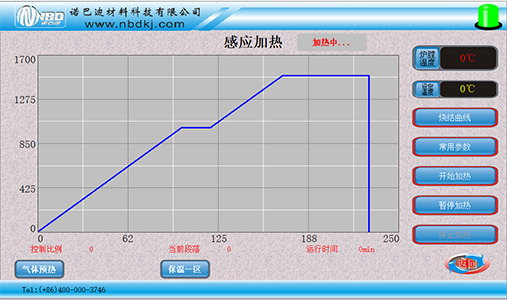

Induction heating control screen |  | |||||||

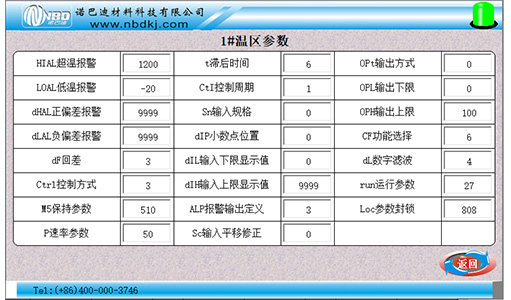

Temperature zone parameter setting screen |  | |||||||

Local picture |

|

| ||||||

Net weight | Approx.740KG | |||||||

Cautions |

| |||||||

Service | One year limited warranty with lifetime support (warranty does not include consumable parts) | |||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|  |  | |

|  |  |  |

推荐产品

Split type mini tube furnace

Thermal insulation refractory product

medium frequency induction melting furnace

Well type molten salt electroplating furnace

Large size tube atmosphere vacuum furnace

Extended heating zone CVD slide tube type furnace

Rotary pendulum oxidation furnace (silicon nitride tube)

Vacuum vibrating vertical tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China