High temp. hydrogen vibrating plate sintering furnace

Release time: 2022-07-09 16:01:16 Number of views: 821

High temperature heating system, automatic control system.

The heating system is composed of control circuit and furnace. The furnace lining uses vacuum forming high-purity aluminum oxide lightweight material, and imported high-temperature alloy resistance wire is used as heating element. Heat-resistant stainless steel tube traverses the middle of the furnace body as the furnace, both ends of the furnace tube are sealed with stainless steel flanges, and the heating element is parallel with the furnace tube, which can effectively ensure the uniformity of the temperature field. The temperature measurement adopts a stable K-type thermocouple to improve the accuracy of temperature control。

Configuration

| The heating system is composed of control circuit and furnace. The furnace lining uses vacuum forming high-purity aluminum oxide lightweight material, and imported high-temperature alloy resistance wire is used as heating element. Heat-resistant stainless steel tube traverses the middle of the furnace body as the furnace, both ends of the furnace tube are sealed with stainless steel flanges, and the heating element is parallel with the furnace tube, which can effectively ensure the uniformity of the temperature field. The temperature measurement adopts a stable K-type thermocouple to improve the accuracy of temperature control. It is a special equipment developed for colleges and universities, scientific research institutes and industrial and mining enterprises to sintering, melting and analyzing metal, non-metal and other compound materials in atmosphere or vacuum. The furnace temperature control panel is an intuitive and simple touch screen, so as to observe the working state of the system at any time. | |||||||

| Model | NBD-T1200-100IIIT2ZD | |||||||

| Electrical Spec. | Three-phase 380V; 50HZ | |||||||

Tmax | 1150℃ | |||||||

rated power | 30KW | |||||||

Touch screen size | 10 inches | |||||||

thermocouple | Type K thermocouple | |||||||

Furnace tube size | φ273*2190mm | |||||||

| Furnace tube material | 310S stainless steel | |||||||

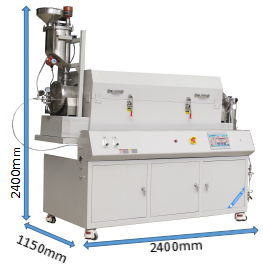

Furnace length | L2400×D1150×H2400mm | |||||||

Recommended heating rate | 10℃/min | |||||||

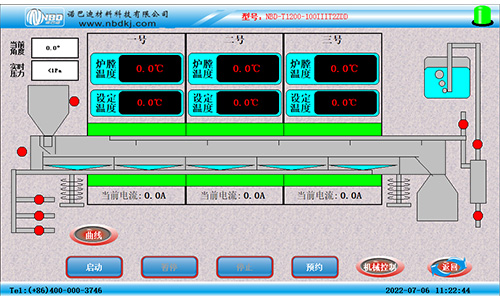

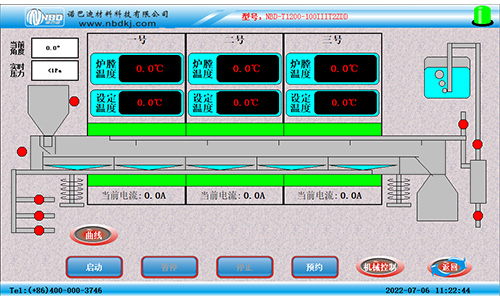

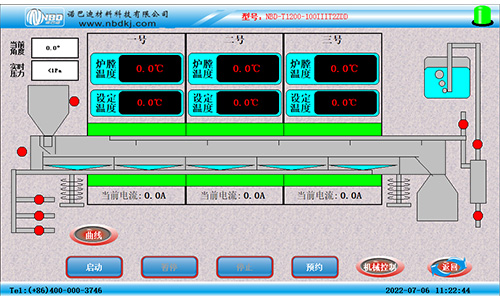

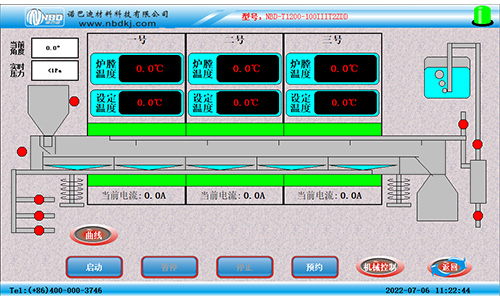

| Control system |

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |||||||

| Main monitoring interface |   | |||||||

| Mechanical operating interface |   | |||||||

Temp. Accuracy | +/- 1 °C | |||||||

Local picture |

|

| ||||||

Net weight | Approx.900KG | |||||||

Cautions | During installation or maintenance, collision with the leading end of the heating wire should be avoided as far as possible to prevent the heating wire from being disconnected. 1, the equipment should be placed in a dry and ventilated place; 2. After the first installation, check whether the equipment is properly connected before use. 3, when the equipment is used, the furnace temperature shall not exceed the rated temperature, so as not to damage the heating element and metal furnace tube. 4. There shall be no conductive dust, explosive gases, corrosive gases and liquids around the equipment. 5, regularly check the electric control box, keep the electric control box clean and dust-free accumulation, cleaning can be cut off the external power with a dry brush or "leather tiger" to purge. 6, During the operation of the equipment, it is necessary to frequently check the change of the exhaust volume and the pressure in the furnace tube to avoid the increase of the pressure in the furnace tube caused by the blockage of the exhaust port. 7. There will be local high temperature phenomenon in the operation of the equipment, please pay attention to prevent burns. 8. After the equipment is turned on, if there is an alarm, the equipment should be checked and removed before running. | |||||||

Service | One year limited warranty with lifetime support (warranty does not include consumable parts) | |||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

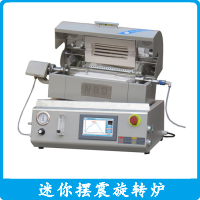

Related products

Configuration

| The heating system is composed of control circuit and furnace. The furnace lining uses vacuum forming high-purity aluminum oxide lightweight material, and imported high-temperature alloy resistance wire is used as heating element. Heat-resistant stainless steel tube traverses the middle of the furnace body as the furnace, both ends of the furnace tube are sealed with stainless steel flanges, and the heating element is parallel with the furnace tube, which can effectively ensure the uniformity of the temperature field. The temperature measurement adopts a stable K-type thermocouple to improve the accuracy of temperature control. It is a special equipment developed for colleges and universities, scientific research institutes and industrial and mining enterprises to sintering, melting and analyzing metal, non-metal and other compound materials in atmosphere or vacuum. The furnace temperature control panel is an intuitive and simple touch screen, so as to observe the working state of the system at any time. | |||||||

| Model | NBD-T1200-100IIIT2ZD | |||||||

| Electrical Spec. | Three-phase 380V; 50HZ | |||||||

Tmax | 1150℃ | |||||||

rated power | 30KW | |||||||

Touch screen size | 10 inches | |||||||

thermocouple | Type K thermocouple | |||||||

Furnace tube size | φ273*2190mm | |||||||

| Furnace tube material | 310S stainless steel | |||||||

Furnace length | L2400×D1150×H2400mm | |||||||

Recommended heating rate | 10℃/min | |||||||

| Control system |

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |||||||

| Main monitoring interface |   | |||||||

| Mechanical operating interface |   | |||||||

Temp. Accuracy | +/- 1 °C | |||||||

Local picture |

|

| ||||||

Net weight | Approx.900KG | |||||||

Cautions | During installation or maintenance, collision with the leading end of the heating wire should be avoided as far as possible to prevent the heating wire from being disconnected. 2. After the first installation, check whether the equipment is properly connected before use. 3, when the equipment is used, the furnace temperature shall not exceed the rated temperature, so as not to damage the heating element and metal furnace tube. 4. There shall be no conductive dust, explosive gases, corrosive gases and liquids around the equipment. 5, regularly check the electric control box, keep the electric control box clean and dust-free accumulation, cleaning can be cut off the external power with a dry brush or "leather tiger" to purge. 6, During the operation of the equipment, it is necessary to frequently check the change of the exhaust volume and the pressure in the furnace tube to avoid the increase of the pressure in the furnace tube caused by the blockage of the exhaust port. 7. There will be local high temperature phenomenon in the operation of the equipment, please pay attention to prevent burns. 8. After the equipment is turned on, if there is an alarm, the equipment should be checked and removed before running. | |||||||

Service | One year limited warranty with lifetime support (warranty does not include consumable parts) | |||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|  |  | |

|  |  |  |

推荐产品

Double deck box furnace

Vacuum molten salt electroplating furnace

0.2L melting furnace 1200℃

2 station glove box

.jpg)

3000℃ ultra-high temperature atmosphere furnace

Pilot scale molten salt electroplating furnace

Pressure rotary tube furnace

Mini hydrogen reduction furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China