Automatic feed anti deposition pyrolysis furnace

Release time: 2022-07-01 10:36:27 Number of views: 1360

Equipment Introduction: Automatic feeding vacuum gasification sintering furnace, maximum temperature of 1200 ℃, stainless steel tube. Two kinds of stainless steel augers with screw pitch of 40 and 60mm can realize different feed speeds and effectively improve the uniformity of material heating temperature and reaction uniformity. Stainless steel vacuum feed tank with a capacity of 4L, and stainless steel water cooled discharge tank with a capacity of 4L is provided on the right side of the equipment. The feed drum is equipped with vibration motors to control feed stability and uniformity. On the left side, the chain wheel drives the auger in the furnace tube to rotate, so as to achieve stable material in and out, and the rotation rate is adjustable. The equipment has three temperature control units, and the length of the temperature zone is 600mm. Through the fast assembly design, it is very convenient to repair and replace the furnace tube and auger. The equipment is mainly used for the pyrolysis treatment of organic solid waste and the continuous sintering experiment under vacuum or atmosphere.

| Equipment characteristics:

| ||||||

Product model | NBD-RT1200-80T3-4L | ||||||

Electrical specifications | AC380V/7.5KW | ||||||

Available temperature | 1200℃(<1H) | ||||||

Continuous temperature | 1000℃(continuity) | ||||||

Achievable heating rate | ≤20℃/min | ||||||

Length of heating zone | φ150×600mm | ||||||

Furnace body size | L 1650 × D 760 × H 1720mm | ||||||

Stainless steel auger |  | ||||||

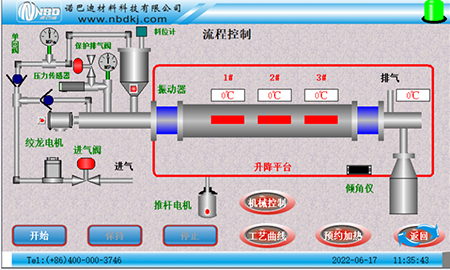

control system |

|

| |||||

Main monitoring interface |  | ||||||

Temperature accuracy | +/- 1 ℃ | ||||||

Heating element, heating element |

| Mo Doped Fe-Cr-Al Alloy | |||||

Gasification outlet end |  | Outlet flare design to avoid clogging | |||||

Equipment details |

|

|

| ||||

Vacuum degree: ≤ 7Pa (mechanical pump) | |||||||

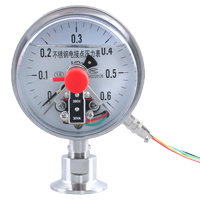

Electric contact pressure gauge |

| When the end face of the clamp is stressed and the diaphragm is exposed, the pressure can be directly felt, which can prevent scaling, unsanitary and viscous pressure blockage. | |||||

weight | ≈300KG | ||||||

Precautions for equipment use | When the equipment hearth temperature is ≥ 300 ℃, do not open the hearth to avoid injury; When the equipment is used, the reading of the absolute pressure gauge shall not be greater than 0.15MPa to prevent equipment damage caused by excessive pressure; When the equipment is used under vacuum, the operating temperature of the equipment shall not exceed 600 ℃.

| ||||||

Service support | Year warranty with lifetime support (excluding consumable parts such as tubes and seals). | ||||||

Disclaimer: the product introduction of the station (including product pictures, product descriptions, technical parameters, etc.) is for reference only. Due to untimely update, there may be some difference between the contents and the actual situation. Please contact our customer service personnel for confirmation. The information provided by this website does not constitute an offer or commitment, and NuCompany will improve and modify any information on the website from time to time without notice.

推荐产品

Thermal Shrinkage and Expansion Tester

Intelligent muffle furnace (4L) 1200℃

.png)

3-heating zone type tube furnace 1200℃

Uniform temperature heating platform

Production-type atmosphere muffle furnace

Industrial rotary pendulum sintering furnace

Large caliber intelligent tube furnace 1200℃

Vertical tube furnace (saturated steam)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China