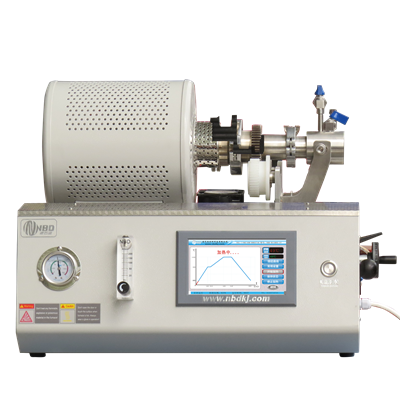

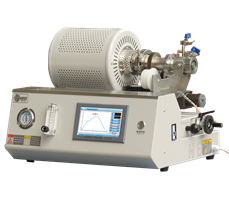

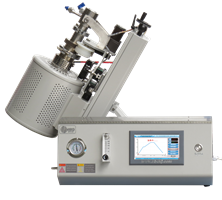

Mini mixing sintering furnace

Release time: 2022-4-24 16:02:36 Number of views: 1463

|

|

|

|

|

|

Configuration

|

|

1. Through constant rotation, the material can be heated and contact with the gas more fully and evenly; |

||||||

|

Model |

NBD-RT1200-50TI |

||||||

|

Electrical Spec |

AC220V 1.2KW |

||||||

|

Tmax |

1200 ℃ |

||||||

|

Max working temps. |

1150 ℃ |

||||||

|

Heating rate |

≤ 10 ℃/min |

||||||

|

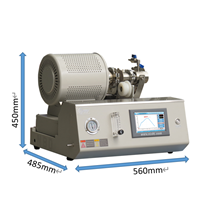

Heating zone size |

φ80*100mm |

||||||

|

Tube size |

Φ50×220mm(One end is sealed ) |

||||||

|

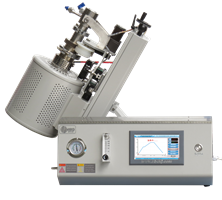

Effective volume |

70ml (Tilt 90 degrees) 48ml (tilt 60 degrees) 33ml (Tilt 45 degrees) 17ml (Tilt 30 degrees)

|

Calculate the constant temperature zone according to the length of temperature zone 50 |

|||||

|

control system |

|

1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; |

|||||

|

Temp Accuracy |

+/- 1 ℃ |

||||||

|

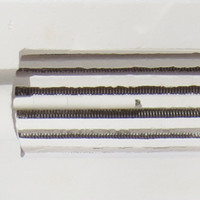

Heating element |

|

Mo-doped Fe-Cr-Al alloy |

|||||

|

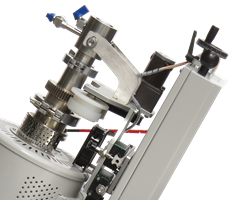

Equipment details |

|

|

|

||||

|

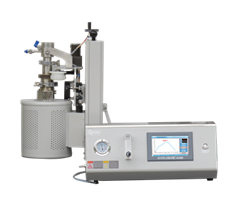

Vacuum degree: ≤10Pa (mechanical pump) |

|||||||

|

Pressure measurement and monitoring |

|

The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. |

|||||

|

净重 |

20KG |

||||||

|

设备使用注意事项 |

1. 设备炉膛温度≥300℃时,禁止打开炉膛,避免受到伤害; 2. 设备使用时,炉管内压力不得超过0.125MPa(绝对压力),以防止压力过大造成设备损坏; 3. 真空下使用时,设备使用温度不得超过800℃。

4. 供气钢瓶内部气压较高,向炉管内通入气体时,气瓶上必须安装减压阀,建议在选购试验用小压力减压阀,减压阀量程为0.01MPa-0.15MPa,使用时会更加精确安全。 5.当炉体温度高于1000℃时,炉管内不可处于真空状态,炉管内的气压需和大气压 相当,保持在常压状态; 6.高纯石英管的长时间使用温度≦1100℃ 7.加热的实验时,不建议关闭炉管法兰端的抽气阀和进气阀使用。若需要关闭气阀对样品加热,则需时刻关注压力表的示数,若绝对压力表读数大于0.15MPa,必须立刻打开排气端阀门,以防意外发生(如炉 管破裂,法兰飞出等) |

||||||

|

服务支持 |

1年质保,提供终身支持(保修范围内不包括易耗部件,例如炉管和密封圈等) |

||||||

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,诺巴迪公司不定期完善和修改网站任何信息,恕不另行通知。

相关产品

|

|

|

||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

Configuration

|

|

1. Through constant rotation, the material can be heated and contact with the gas more fully and evenly; |

||||||

|

Model |

NBD-RT1200-50TI |

||||||

|

Electrical Spec |

AC220V 1.2KW |

||||||

|

Tmax |

1200 ℃ |

||||||

|

Max working temps. |

1150 ℃ |

||||||

|

Heating rate |

≤ 10 ℃/min |

||||||

|

Heating zone size |

φ80*100mm |

||||||

|

Tube size |

Φ50×220mm(One end is sealed ) |

||||||

|

Effective volume |

70ml (Tilt 90 degrees) 48ml (tilt 60 degrees) 33ml (Tilt 45 degrees) 17ml (Tilt 30 degrees)

|

Calculate the constant temperature zone according to the length of temperature zone 50 |

|||||

|

control system |

|

1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; |

|||||

|

Temp Accuracy |

+/- 1 ℃ |

||||||

|

Heating element |

|

Mo-doped Fe-Cr-Al alloy |

|||||

|

Equipment details |

|

|

|

||||

|

Vacuum degree: ≤10Pa (mechanical pump) |

|||||||

|

Pressure measurement and monitoring |

|

The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. |

|||||

|

净重 |

20KG |

||||||

|

设备使用注意事项 |

1. 设备炉膛温度≥300℃时,禁止打开炉膛,避免受到伤害; 2. 设备使用时,炉管内压力不得超过0.125MPa(绝对压力),以防止压力过大造成设备损坏; 3. 真空下使用时,设备使用温度不得超过800℃。

4. 供气钢瓶内部气压较高,向炉管内通入气体时,气瓶上必须安装减压阀,建议在选购试验用小压力减压阀,减压阀量程为0.01MPa-0.15MPa,使用时会更加精确安全。 5.当炉体温度高于1000℃时,炉管内不可处于真空状态,炉管内的气压需和大气压 相当,保持在常压状态; 6.高纯石英管的长时间使用温度≦1100℃ 7.加热的实验时,不建议关闭炉管法兰端的抽气阀和进气阀使用。若需要关闭气阀对样品加热,则需时刻关注压力表的示数,若绝对压力表读数大于0.15MPa,必须立刻打开排气端阀门,以防意外发生(如炉 管破裂,法兰飞出等) |

||||||

|

服务支持 |

1年质保,提供终身支持(保修范围内不包括易耗部件,例如炉管和密封圈等) |

||||||

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,诺巴迪公司不定期完善和修改网站任何信息,恕不另行通知。

相关产品

|

|

|

||

|

|

|

|

|

推荐产品

Liquid vapor phase generator, type Ι

Automatic hydrogen making machine H500

vacuum oven

1200 ℃ CVD integrated machine

System O1200-XT22D2F

3D printing vacuum furnace

Four-way float proportioning gas supply tank

Experimental hydrogen reduction furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China