High temperature physical property test system

Release time: 2022-04-21 09:41:39 Number of views: 811

Equipment introduction:

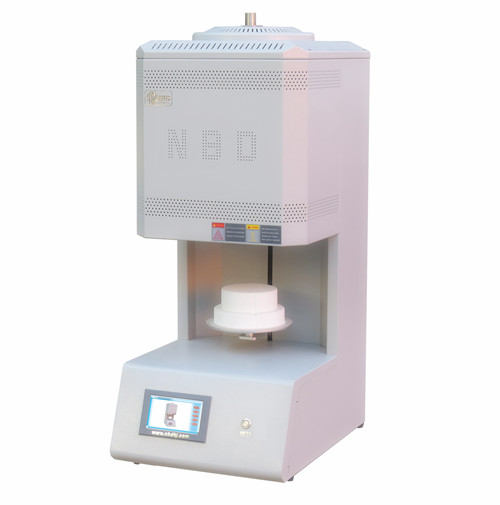

The NOBODY high temperature physical properties test system, based on the NOBODY vertical vacuum tube furnace, can provide vacuum and atmosphere protection conditions, and is widely used to test the physical properties of substances at different temperatures such as viscosity and expansion.

The test system extension platform provides a variety of application interfaces, can be adapted to a variety of test components according to the experimental requirements, and the test field is wide.

Heating system and physical characteristics test system independent control, full touch screen intelligent human-computer interaction interface, easy to operate. Test data can be visualized and stored and exported as needed.

The test system can also be used as an independent vacuum vertical tube furnace, the highest temperature is 1700 degrees Celsius, the use of high purity silicon molybdenum rod as a heating element, high purity alumina fiber furnace, temperature control accuracy, temperature field uniformity.

Configuration

| 1. The heating element is distributed in a ring inside the furnace, and the furnace tube is surrounded 360 degrees to improve the temperature uniformity in the furnace; | ||||||||||||||

Model | NBD-LT1700-80TI | ||||||||||||||

Electrical Spec. | AC220V 1.8KW | ||||||||||||||

Tmax | 1650 ℃ | ||||||||||||||

The heating rate can be reached | ≤ 20 ℃/min | ||||||||||||||

Length of heating zone | 300mm | ||||||||||||||

Furnace tube size | Φ80*1000mm | ||||||||||||||

Control system |

| 1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |||||||||||||

Temp. Accuracy | +/- 1 ℃ | ||||||||||||||

Heating element | |||||||||||||||

Equipment details |

|

|

| ||||||||||||

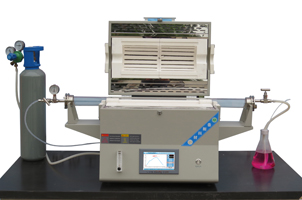

Vacuum degree: ≤10Pa (mechanical pump) | |||||||||||||||

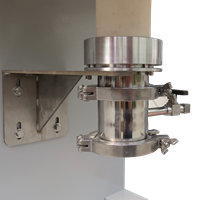

Pressure measurement and monitoring |

| The mechanical pressure gauge with damping oil is used to make the pressure fluctuation produce damping and reduce the pointer swinging back and forth. | |||||||||||||

gas supply system |

| The float flowmeter is used to control the gas flow rate, which is integrated with the equipment, and the leakage test has been carried out before the factory. | |||||||||||||

Cautions | 1. When the equipment is used, the absolute pressure gauge reading should not be greater than 0.15MPa to prevent equipment damage caused by excessive pressure; | ||||||||||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable parts such as furnace tubes and seals) | ||||||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

Well type vacuum atmosphere furnace

Vacuum high-frequency induction melting furnace

Vacuum molten salt electroplating furnace

Vertical HVPE single crystal growth system

Large capacity bottom-loading furnace

Single temperature zone tube furnace 1200℃

Intelligent tube furnace 1700℃

Large size hydrogen reduction furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China