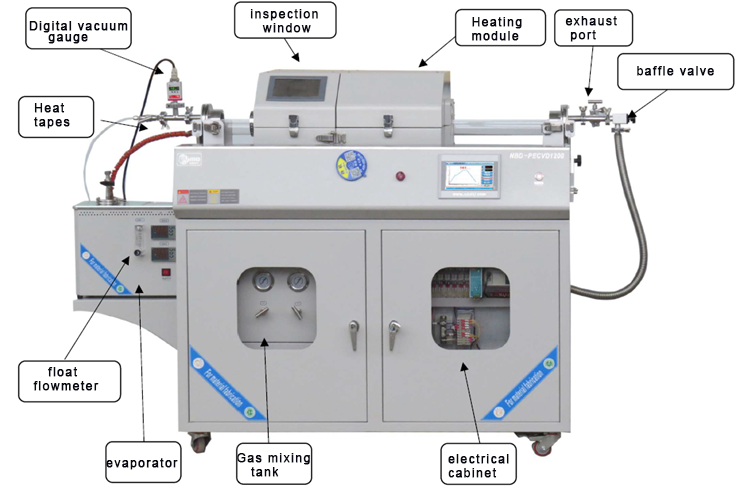

PECVD system

Release time: 2022-4-15 14:22:11 Number of views: 2190

|

|

Equipment introduction:

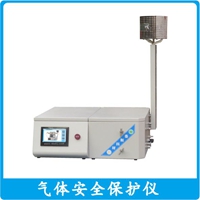

The PECVD system is equipped with a high precision fully enclosed liquid gasification unit to provide gasification conditions including toxic liquids for surface film deposition experiments. The system is composed of high stability RF power supply (200W, 13.56MHz), gas flow control system and vacuum system. It adopts NOBODY operating software of NBD-101EP centralized bus control technology. Plasma properties are used to control or influence the process of gas reaction and chemical reaction on the material surface and to deposit thin films at appropriate temperatures. PECVD deposited films have excellent electrical properties, good substrate adhesion and excellent step coverage. Because of these advantages, it has a wide range of applications in VLSI, photoelectric devices, MEMS and other fields.

|

|

|

|

|

|

|

Configuration

|

Main features: |

|||

|

Model |

NBD-PE1200-80TID2FY |

|||

|

AC220V 50/60HZ |

||||

|

Temp Accuracy |

±1℃ |

|||

| Touch screen size |

7 inches |

|||

|

13.56MHz |

||||

|

Rf power output range |

0-200W |

|||

|

Deposition heating rating |

4.0KW |

|||

|

Rated evaporator power |

1.3KW |

|||

|

Tracking zone rating |

75W |

|||

|

Sensor type |

Type K thermocouple |

|||

|

Maximum deposition temperature |

1200℃ |

|||

|

Rated deposition temperature |

1150℃ |

|||

|

Rated evaporator temperature |

400℃ |

|||

|

150℃ |

||||

|

Recommended heating rate |

≤10/min |

|||

|

Deposition tube diameter |

Φ80mm*1200mm |

|||

|

Pipe diameter of evaporation source |

Φ50mm*80mm |

|||

|

Effective volume of evaporation source |

50ml |

|||

|

Boundary dimension(PECVD) |

L1500×H1280×D760mm |

|||

|

Boundary dimension(evaporator) |

L410×H350×D210mm |

|||

|

Atmospheric condition |

Gas mixture, vacuum, etc |

|||

|

Mechanical pump pumping rate |

16 m3 /h

|

|||

|

Maximum vacuum of furnace chamber |

3~5Pa |

|||

|

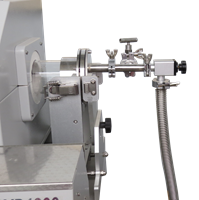

Flange construction |

Aviation aluminum fast opening mode; |

|||

|

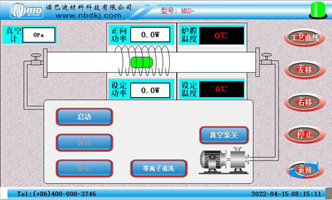

Operating system |

NBD-101EP centralized bus control integrated system, 7" full touch screen control, intelligent fuzzy PID control; Intelligent man-machine dialogue mode; |

|||

|

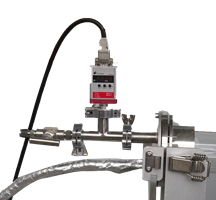

Vaccum test |

Digital vacuum gauge; |

|||

|

Equipment details |

|

|

|

|

|

Control system |

|

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; 2, can be booked sintering, unattended sintering process curve sintering; 3, real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless record; 4, with remote control, real-time observation of equipment status; 5. Temperature correction: the difference between the main control temperature and the sample temperature, and the whole sintering process is nonlinear correction. |

||

|

Partial interface |

|

|

||

|

Net weight |

Approx.300KG |

|||

|

Cautions |

1. The RF matcher is generally in the automatic matching state, and the general power needs to reach more than 50W to match; |

|||

|

Service |

One year limited warranty to provide lifelong support; |

|||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|||

|

|

|

|

|

|

|

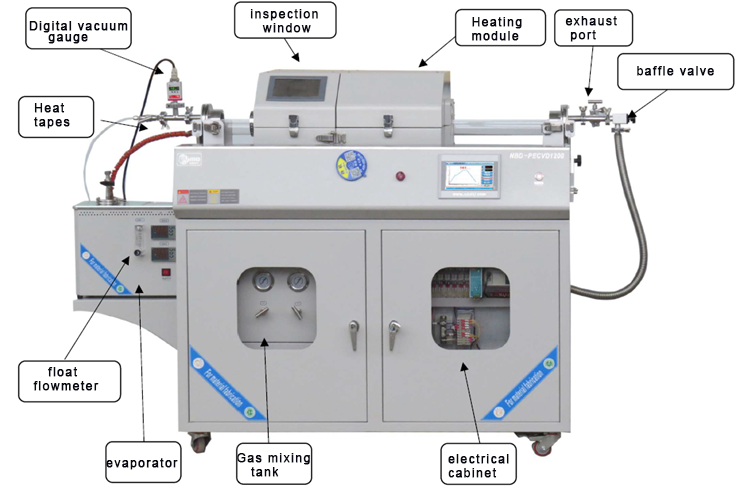

Equipment introduction:

The PECVD system is equipped with a high precision fully enclosed liquid gasification unit to provide gasification conditions including toxic liquids for surface film deposition experiments. The system is composed of high stability RF power supply (200W, 13.56MHz), gas flow control system and vacuum system. It adopts NOBODY operating software of NBD-101EP centralized bus control technology. Plasma properties are used to control or influence the process of gas reaction and chemical reaction on the material surface and to deposit thin films at appropriate temperatures. PECVD deposited films have excellent electrical properties, good substrate adhesion and excellent step coverage. Because of these advantages, it has a wide range of applications in VLSI, photoelectric devices, MEMS and other fields.

|

|

|

|

|

|

|

Configuration

|

Main features: |

|||

|

Model |

NBD-PE1200-80TID2FY |

|||

|

AC220V 50/60HZ |

||||

|

Temp Accuracy |

±1℃ |

|||

| Touch screen size |

7 inches |

|||

|

13.56MHz |

||||

|

Rf power output range |

0-200W |

|||

|

Deposition heating rating |

4.0KW |

|||

|

Rated evaporator power |

1.3KW |

|||

|

Tracking zone rating |

75W |

|||

|

Sensor type |

Type K thermocouple |

|||

|

Maximum deposition temperature |

1200℃ |

|||

|

Rated deposition temperature |

1150℃ |

|||

|

Rated evaporator temperature |

400℃ |

|||

|

150℃ |

||||

|

Recommended heating rate |

≤10/min |

|||

|

Deposition tube diameter |

Φ80mm*1200mm |

|||

|

Pipe diameter of evaporation source |

Φ50mm*80mm |

|||

|

Effective volume of evaporation source |

50ml |

|||

|

Boundary dimension(PECVD) |

L1500×H1280×D760mm |

|||

|

Boundary dimension(evaporator) |

L410×H350×D210mm |

|||

|

Atmospheric condition |

Gas mixture, vacuum, etc |

|||

|

Mechanical pump pumping rate |

16 m3 /h

|

|||

|

Maximum vacuum of furnace chamber |

3~5Pa |

|||

|

Flange construction |

Aviation aluminum fast opening mode; |

|||

|

Operating system |

NBD-101EP centralized bus control integrated system, 7" full touch screen control, intelligent fuzzy PID control; Intelligent man-machine dialogue mode; |

|||

|

Vaccum test |

Digital vacuum gauge; |

|||

|

Equipment details |

|

|

|

|

|

Control system |

|

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; 2, can be booked sintering, unattended sintering process curve sintering; 3, real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless record; 4, with remote control, real-time observation of equipment status; 5. Temperature correction: the difference between the main control temperature and the sample temperature, and the whole sintering process is nonlinear correction. |

||

|

Partial interface |

|

|

||

|

Net weight |

Approx.300KG |

|||

|

Cautions |

1. The RF matcher is generally in the automatic matching state, and the general power needs to reach more than 50W to match; |

|||

|

Service |

One year limited warranty to provide lifelong support; |

|||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|||

|

|

|

|

|

推荐产品

porcelain furnace

Extended heating zone CVD slide tube type furnace

Graphite heater furnace

Observation window muffle furnace

Program controlled large vacuum drying oven

Anti-corrosion mini chamber furnace

Mini vacuum furnace for glove box

PECVD system

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China