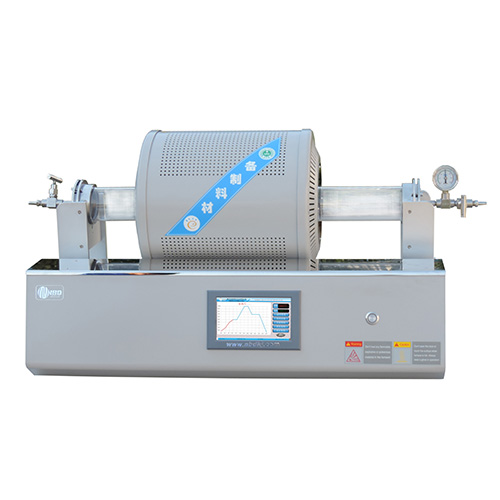

Constant pressure vacuum rotary pendulum sintering furnace

Release time: 2022-04-02 08:16:03 Number of views: 878

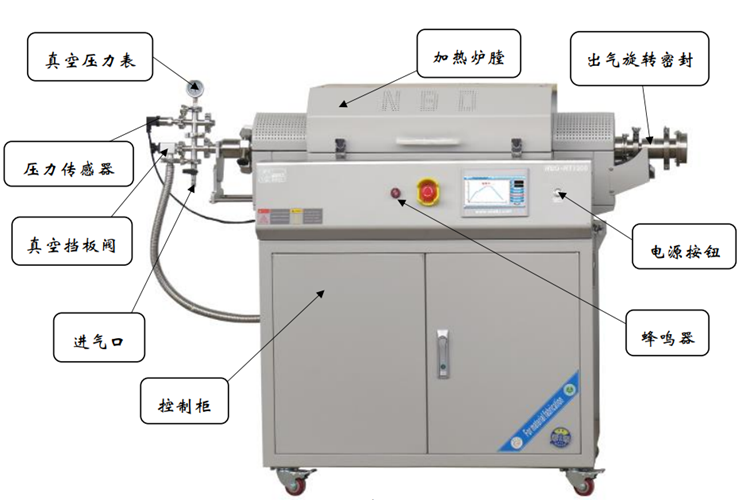

It consists of heating system, furnace body lifting system, furnace tube rotating system, vacuum system and gas inlet and outlet system. The heating system adopts the circular furnace structure of high purity alumina fiber. Imported electric heating wire is used as the heating element. The heating element is distributed around the circumference, which makes the temperature field distribution more uniform.

The furnace body lifting system is mainly used for material loading and the furnace body can tilt a large Angle after the material is fired to facilitate the material pouring out; The furnace body is provided with a dip sensor, we can set any allowed range of Angle according to the need, and then the push rod will push the furnace body automatically to reach the Angle we set, more convenient and quick to use;

By default, as long as heating starts, the rotation of the furnace tube will be automatically opened, so as to better protect the furnace tube. Under high temperature, the furnace tube depends on the support on both sides, and the middle furnace part has no support point. In this way, the rotating furnace tube can effectively prevent the deformation of the middle part of the furnace tube.

Configuration

| 1. The equipment consists of heating system, furnace body lifting system, furnace tube rotation system, vacuum system and gas inlet and outlet system. | ||||||||

Model | NBD-RT1200-120I3TD2ZY | ||||||||

Electrical Spec | three phase 380V 50HZ | ||||||||

Tmax | 1200℃ | ||||||||

Max working temps. | 1150℃ | ||||||||

Heating rate | 10℃/min | ||||||||

Heating zone size | φ150*600mm | ||||||||

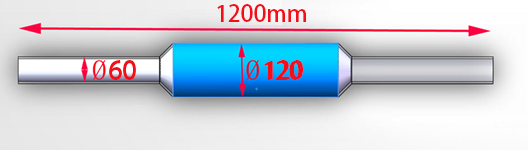

Furnace tube material and size | Quartz tube with bulging belly; The two sides are φ60mm, the middle is φ120mm, the total length is 1200mm

| ||||||||

| Horizontal effective volume of furnace tube | 1L | ||||||||

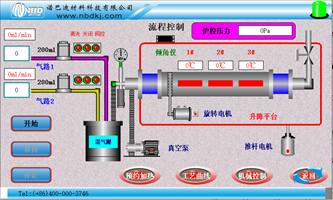

angle of inclination | 30 degrees (discharge) ~2 degrees (feed) | ||||||||

Furnace tube rotation speed | 0.1~5 RPM | ||||||||

Furnace structure | The furnace can be opened, and the φ100mm and φ80mm tube diameters can be changed according to the different furnace tubes used, and the rotation function can be realized, the speed is 0-12.6r/min. | ||||||||

Control system |

| 1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely;

| |||||||

Temp Accuracy | +/- 1 ℃ | ||||||||

Heating element |

| Mo-doped Fe-Cr-Al alloy | |||||||

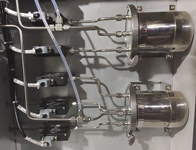

Sealing system | 1. High vacuum MHD rotary seal; | ||||||||

Pressure measurement and monitoring |

| 1. The mechanical pressure gauge with damping oil can prevent the pressure gauge pointer from being damaged, and the pressure sensor can accurately display the internal force change of the furnace tube in real time; | |||||||

Gas supply system |

| The two-channel mass flowmeter control system can accurately control the intake volume. | |||||||

Net weight | 180KG | ||||||||

Safety function | 1. With overtemperature alarm, broken couple prompt, leakage protection, etc.; 2. Electromagnetic pressure relief valve, overpressure automatically deflate; | ||||||||

optional function | Remote monitoring:

| ||||||||

Equipment usage precautions | When the furnace temperature of the equipment is ≥ 300 ℃, it is forbidden to open the furnace to avoid injury;

| ||||||||

Service Support | One year limited warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and seals). | ||||||||

Related products

|

|

|

|

|

|

|

|

推荐产品

Lift type large capacity sintering furnace

CVD system HR1200-110TID3F

MiNi tube furnace 1200℃

Ultrasonic atomizing CVD tube furnace

Vacuum molten salt electroplating furnace

Push-pull tube sintering furnace

PECVD Plasma Chemical Vapor Deposition System

Slide rail rapid annealing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China