Insulation sheet die

Release time: 2022-03-31 08:25:23 Number of views: 3181

The combination of insulation die and powder tablet machine is an essential tool for infrared, fluorescence, calcium and iron analysis instruments, and an indispensable tool for the analysis and research of new powder materials in various fields.

In addition to the standard pressure mould, there are vacuumable cylindrical mould, large cylindrical mould with spring, open flap mould (round, rectangular, shaped), hot pressing mould, insulation mould, etc.

The insulation pressure mold is made of PEEK material, which has the characteristics of high hardness, good toughness, excellent finish, accurate precision and long life.

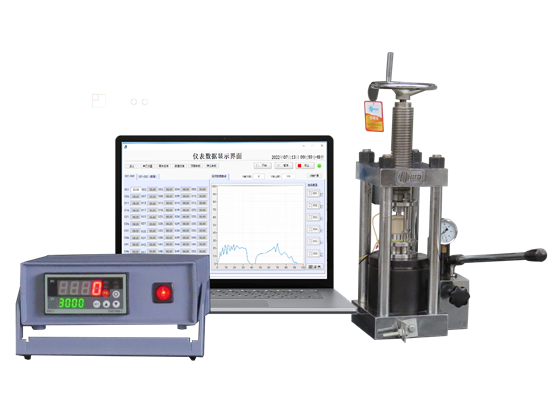

(Insulation mold pressure test system )

)

Parameter

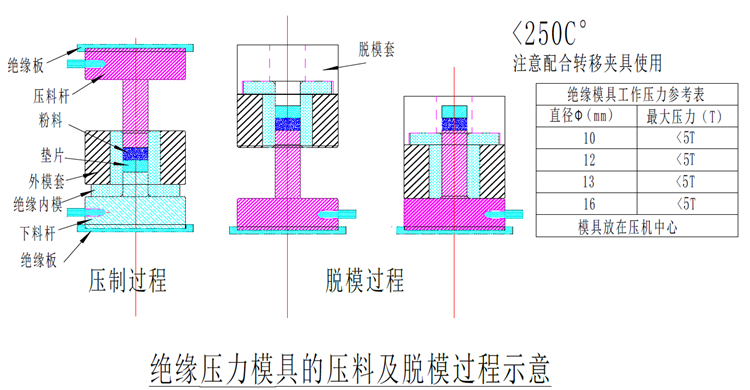

Tablet diameter | working pressure | hight(mm) | Fit the tablet press | Outer mold cover material | ||||

10mm | <5T | 80 | 15T/20T/24T | Polyether ether ketone (PEEK beige) | ||||

12mm | <5T | 80 | 15T/20T/24T | Polyether ether ketone (PEEK beige) | ||||

16mm | <5T | 80 | 24T/30T | Polyether ether ketone (PEEK beige) | ||||

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice. | ||||||||

推荐产品

Vacuum high-frequency induction melting furnace

Cold wall rapid annealing furnace

Anaerobic molten salt electroplating furnace

Thermal insulation refractory product

Ion sputtering device

Plasma cleaner

Open Mini Rotary Stove

Split type mini tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China