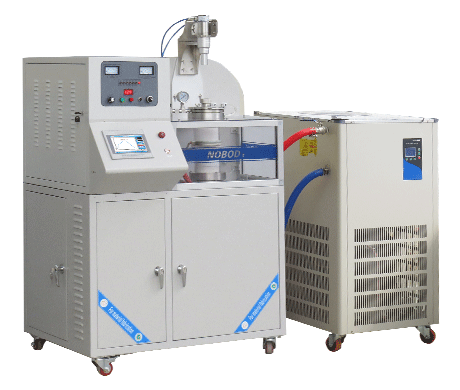

High temperature vacuum induction furnace

Release time: 2022-3-24 10:35:11 Number of views: 1306

|

|

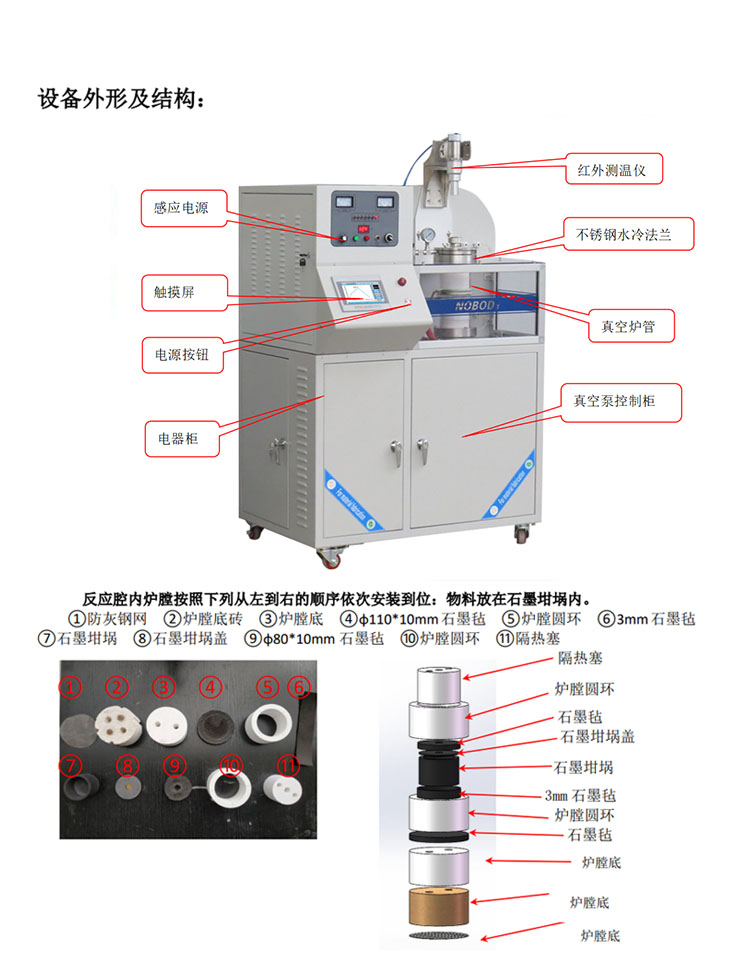

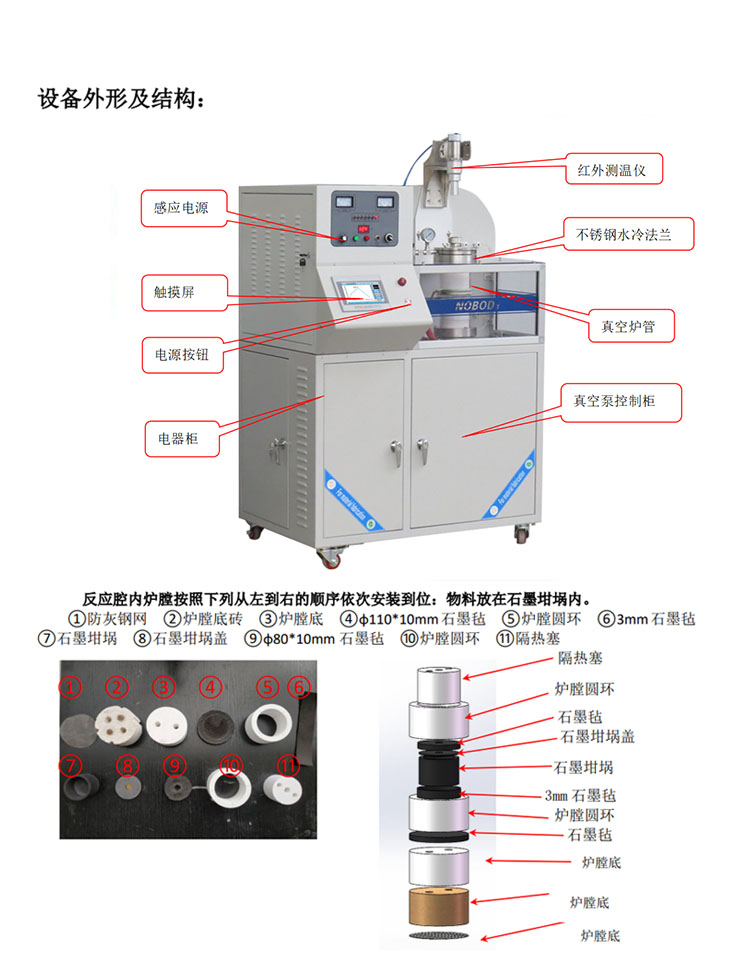

Equipment introduction:

|

||

|

|

|||

Configuration

|

|

The vacuum circulation system includes vacuum pump and vacuum pump high vacuum electromagnetic baffle valve, which can automatically cut off the connection between the pump and prevent the pump from returning oil while maintaining the vacuum in the chamber.

|

||||||||||||

|

Model |

NBD-VAIP2200-80TIDFY50L |

||||||||||||

|

Rated power |

AC380V 25KW |

||||||||||||

|

Touch screen size |

Seven inches | ||||||||||||

|

Sensor type |

Two-color infrared thermometer STRONG-SR-7030-V (700-3000℃) |

||||||||||||

|

Tmax |

2000℃ |

||||||||||||

|

Temp Accuracy |

+/- 1℃ |

||||||||||||

|

Rated temperature |

1900℃ |

||||||||||||

|

Recommended heating rate |

≤400℃/min |

||||||||||||

|

Temperature zone dimension length |

Effective temperature zone φ80*80mm |

||||||||||||

|

Furnace tube material and size |

quartz Ø120*320mm |

||||||||||||

|

Crucible material and size |

High purity graphite φ65 (inside) *40mm |

||||||||||||

|

System vacuum |

3-5Pa(Molecular pump optional) |

||||||||||||

|

炉体外形净尺寸 |

长1000×高1650×深770mm |

||||||||||||

|

温度精度 |

+/- 1℃ |

||||||||||||

|

净重 |

≈160KG |

||||||||||||

|

加热元件 |

感应线圈φ10mm圆铜管内径130mm*3圈 |

||||||||||||

|

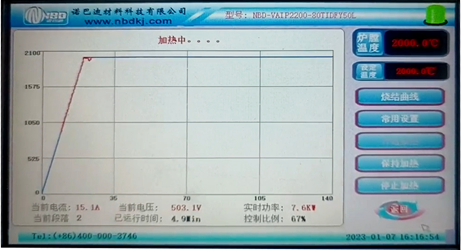

控制系统 |

1、烧结工艺曲线设置:动态显示设置曲线,设备烧结可预存多条工艺曲线,每条工艺曲线可自由设置; 2、可预约烧结,实现无人值守烧结工艺曲线烧结; 3、实时显示烧结功率电压等信息并记录烧结数据,并可导出实现无纸记录; 4、具有实现远程操控,实时观测设备状态; 5、温度校正:主控温度和试样温度的差值,烧结全程进行非线性修正。 |

||||||||||||

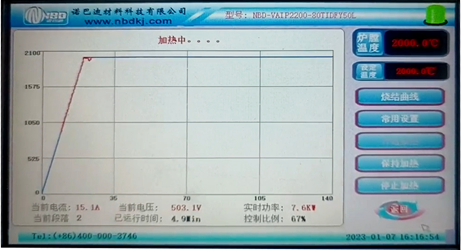

| 运行界面 |

|

||||||||||||

|

|||||||||||||

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,诺巴迪公司不定期完善和修改网站任何信息,恕不另行通知。

相关产品

|

|

|

|

|

|

|

Equipment introduction:

|

||

|

|

|||

Configuration

|

|

The vacuum circulation system includes vacuum pump and vacuum pump high vacuum electromagnetic baffle valve, which can automatically cut off the connection between the pump and prevent the pump from returning oil while maintaining the vacuum in the chamber.

|

||||||||||||

|

Model |

NBD-VAIP2200-80TIDFY50L |

||||||||||||

|

Rated power |

AC380V 25KW |

||||||||||||

|

Touch screen size |

Seven inches | ||||||||||||

|

Sensor type |

Two-color infrared thermometer STRONG-SR-7030-V (700-3000℃) |

||||||||||||

|

Tmax |

2000℃ |

||||||||||||

|

Temp Accuracy |

+/- 1℃ |

||||||||||||

|

Rated temperature |

1900℃ |

||||||||||||

|

Recommended heating rate |

≤400℃/min |

||||||||||||

|

Temperature zone dimension length |

Effective temperature zone φ80*80mm |

||||||||||||

|

Furnace tube material and size |

quartz Ø120*320mm |

||||||||||||

|

Crucible material and size |

High purity graphite φ65 (inside) *40mm |

||||||||||||

|

System vacuum |

3-5Pa(Molecular pump optional) |

||||||||||||

|

炉体外形净尺寸 |

长1000×高1650×深770mm |

||||||||||||

|

温度精度 |

+/- 1℃ |

||||||||||||

|

净重 |

≈160KG |

||||||||||||

|

加热元件 |

感应线圈φ10mm圆铜管内径130mm*3圈 |

||||||||||||

|

控制系统 |

1、烧结工艺曲线设置:动态显示设置曲线,设备烧结可预存多条工艺曲线,每条工艺曲线可自由设置; 2、可预约烧结,实现无人值守烧结工艺曲线烧结; 3、实时显示烧结功率电压等信息并记录烧结数据,并可导出实现无纸记录; 4、具有实现远程操控,实时观测设备状态; 5、温度校正:主控温度和试样温度的差值,烧结全程进行非线性修正。 |

||||||||||||

| 运行界面 |

|

||||||||||||

|

|||||||||||||

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,诺巴迪公司不定期完善和修改网站任何信息,恕不另行通知。

相关产品

|

|

|

|

|

推荐产品

Bottom-loading high temperature sintering furnace

Large size hydrogen reduction furnace

Well type melting furnace 0.45L1200℃

CVD system T1700-XTIG2Z

Anti-corrosion mini chamber furnace

air blast drying oven

Pilot scale molten salt electroplating furnace

TGB-2 Vacuum glove box

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China