Microwave high temp muffle furnace

Release time: 2024-09-04 15:30:15 Number of views: 1654

NBD-WBM1700 series microwave high temperature furnace is a fine type of furnace body, electrical control in a cabinet microwave high temperature sintering equipment. The system uses 1700℃ insulation material, high temperature absorption material up to 1650℃ microwave sintering and high temperature microwave synthesis equipment, it has the characteristics of fast heating speed, high efficiency, good material consistency and so on.

It is suitable for experimental study of synthesis, ashing, expansion, heat treatment, roasting, calcination, sintering and other processes under air atmosphere. In addition to the advantages of high temperature microwave oven and sintering technology, such as "high, low, fast and low", the furnace also has a wide range of applications, easy operation and good equipment stability. The furnace is especially suitable for experimental research and development of new materials, which can achieve high quality and efficient firing of small batch products.

Configuration details

| Technical features: 1) Easy to use, clean, efficient, safe and reliable, and uniform and stable heating, significantly improving product consistency and yield; 2) Safe and reliable full microwave shielding cavity design; 3) Equipped with a continuously adjustable high-stability long-life dedicated industrial microwave source; 4) Features a simple operation control system; 5) Elegant appearance, compact structure, small size, easy to use and maintain; 6) Touch screen operation, intuitive display of temperature curve; | |||||

Application field | 1. Inorganic powder synthesis 3 Electronic ceramic powders: barium titanate, barium strontium titanate, strontium titanate, barium zirconate titanate, etc. 4 Lithium-ion battery cathode materials: lithium cobalt oxide, lithium manganese oxide, etc. 5 Various colorants, glazes, inorganic pigments, etc. 6 Other inorganic powders: manganese oxide, lithium yttrium oxide, zinc ferrite, tricolor fluorescent red powder, glass, cement, etc. 2) Sintering of electronic ceramics Varistors, thermistors, piezoelectric ceramics, microwave dielectric ceramics, etc. 3) Sintering of oxide ceramics and refractory materials Alumina, zirconia, magnesia, and other oxide composite materials, etc. 4) Sintering of magnetic materials Ni-Zn ferrites, gyratory ferrites, etc. 5) Ashing, incineration, burn-off tests. | |||||

Product Model | NBD-WBM1700-14TI | |||||

| Work environment | 1) A stable power supply of AC 220V±10V, 50Hz; 2) Clean water source; 3) Environmental conditions: Temperature: 5~40℃ Humidity: 5~85% | |||||

Electrical Specifications | AC220V/3KW | |||||

Reachable temperature | 1650℃ | |||||

| Temperature measurement method | Infrared thermometer | |||||

| Temperature measurement range | 250℃~1650℃ | |||||

Output power | 0.2~1.4kW 连续可调 | |||||

Microwave output frequency | 2.45 GHz±25MHz | |||||

Microwave leakage rate | <2mW/cm² | |||||

Cooling method | Water cooling | |||||

Casting box internal dimensions (length * height * depth) | Length × Width × Depth=85×85×30(mm) | |||||

Size, dimensions, and weight | Length × Width × Depth=590×680×680(mm) | |||||

| Weight | 75KG | |||||

control system |

| NBD-101P embedded operating system; 1. Uses custom industrial-grade microwave sources to ensure continuous and stable long-term operation of the equipment; 2. Can achieve ultra-fast heating and significantly shorten the temperature maintenance time, improving experimental efficiency several times over; 3. Microwave output power is continuously adjustable, allowing for precise temperature control curves; 4. Uses imported high-precision infrared thermometers to directly measure sample temperature; 5. Provides three operation modes: manual, automatic, and constant temperature, with free switching between them; 6. Can set and store multiple temperature control curves; operation records are automatically stored and compatible with printers; real-time temperature control curve display enables dynamic monitoring of the heating process; | ||||

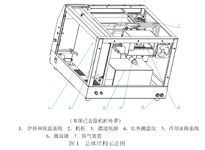

Structural Simplification |

| |||||

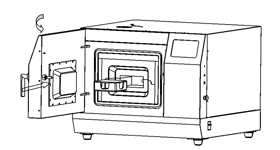

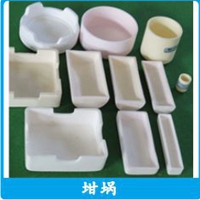

Loading material |

| |||||

Equipment usage precautions | 1. Microwave source equipment operates under high voltage and has stringent requirements for the working environment; it should avoid use in areas with high humidity and dust. 2. If microwave source equipment is improperly operated, there is a risk of electric shock from high voltage and exposure to microwave radiation; the high voltage of the microwave source can be fatal, so operators must be trained personnel who have received rigorous professional training and possess relevant knowledge and experience. 3. When maintaining the high-voltage power supply section, residual voltage may remain in the equipment even if the power switch is turned off; if necessary, the high-voltage capacitor should be short-circuited to discharge. 4. Before each use of the microwave source, all safety systems must be correctly in place and functioning properly. 5. Microwave leakage must be regularly and compulsorily checked; at a distance of 5 cm from the measuring point, and under normal operating conditions, the microwave leakage should not exceed 5 mW/cm3. If the specified value is exceeded, troubleshooting should be performed according to the instructions. 6. Before each start-up of the microwave source, it is essential to check and ensure that the water-cooling circulation system is activated and operating normally; otherwise, the equipment must not be started to prevent damage to the microwave source. 7. The cooling circulating water used by the microwave source should meet the water quality requirements specified in GB10067.1-88, with total hardness (CaO mg equivalent) less than 10, inlet water temperature between 5-30°C, outlet water temperature below 50°C, and working pressure between 0.06 to 0.12 MPa. The cooling waterways should be cleaned periodically (recommended every three months); if the cooling waterways are blocked, it will cause overheating of the magnetron, shorten its lifespan, or even burn it out. 8. The microwave source is easily damaged when operating under overcurrent, overvoltage, excessive power, or poor cooling conditions; especially its core component, the magnetron, is very delicate and expensive. Therefore, during long-term operation, the anode current should be kept below the rated value to ensure the lifespan of the magnetron. 9. The interior of the microwave sintering furnace must be frequently cleaned to remove all deposits, including those on the waveguide window; any mixed metals and other foreign objects that could cause arcing should be removed. Deposits on the waveguide window, blind plates, etc., should be frequently cleaned with alcohol and kept clean. If the waveguide window is contaminated, it will block the microwave energy from entering the sintering furnace or generate intense heat on its surface, leading to high-frequency arcing; in severe cases, it can damage the microwave source. 10. When sintering materials with volatiles and corrosive properties, the impact of these materials on the equipment and protective measures must be fully considered; particular attention should be paid to the effects of material volatilization on the waveguide window, observation window, blind plates, and temperature measurement windows during the sintering process. | |||||

Service Support | 1-year warranty, lifetime support provided (warranty does not include consumable parts, such as crucibles and seals)。 | |||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

Related products

推荐产品

Automatic hydrogen making machine H500

Constant voltage control system

High pressure tube furnace (single head 1200°C)

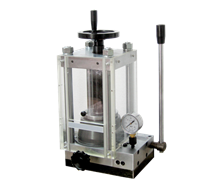

Manual tablet press

3C vacuum pump

Vertical tube furnace 1500℃

Intelligent double temperature zone tube furnace 1500℃

Mesh belt brazing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China