High temperature frit furnace

Release time: 2021-11-29 09:43:17 Number of views: 1342

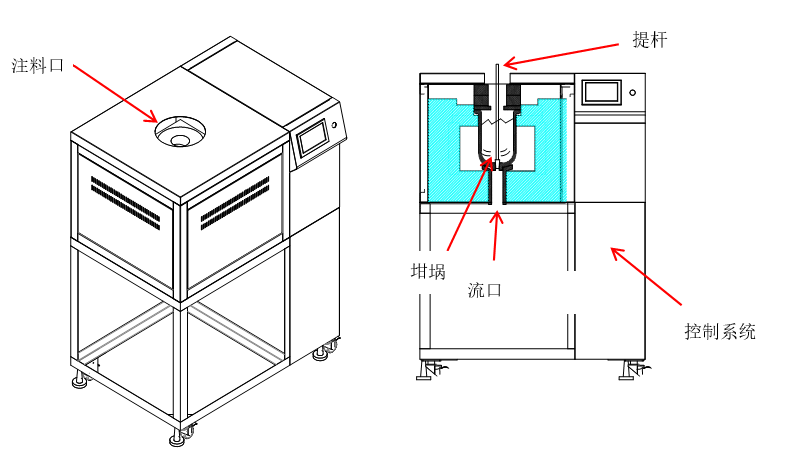

PL series vertical high temperature frit furnace adopts international advanced manufacturing technology as a whole, and is designed from the perspective of aesthetics and art according to the perspective of human safety. The furnace is made of high purity alumina light fiber material, and the control interface is made of large size touch screen for simpleton operation. The control mathematical model adopts advanced PID self-learning fuzzy control to keep the temperature control accuracy at ±1℃. After long-term and repeated experiments on various samples, it can almost be applied to the melting and roasting of ceramics, glass, enamel, etc., in addition to the toxic and harmful and explosive samples, for the preparation of glass materials, glass low-temperature cosolvent, enamel glaze, bond, etc. Alloy material melting and quenching operation, the container using zircon quartz crucible, high temperature resistance and thermal shock resistance is good. It can ensure the consistency of the quality of your samples.

Configuration

| 1, the furnace lining uses vacuum forming high-purity alumina poly light material, the surface is coated with high reflectivity ultra-high temperature coating, zircon quartz crucible placed in the middle of the furnace, in addition to maintaining the minimum loss of energy, but also to enhance the stability of high temperature performance, will not indirectly pollute the sample. | ||

Model | NBD-PL1700-5LTI | ||

Electrical Spec | 3-phase AC380V | ||

Tmax | 1650℃ | ||

Recommended heating rate | ≤10℃/min | ||

Zirconium crucible volume | 5L;(1.6L,3L,5L,10L,17L and other specifications are available) | ||

Crucible material |

| Adopt high purity zircon quartz crucible, high temperature resistance and good thermal shock resistance. | |

Temp Accuracy | +/- 1℃ | ||

Heating element |

| High purity silicon molybdenum rod | |

Net weight | 370KG | ||

Cautions | After melting, when taking out the plug, be sure to wear high temperature gloves to avoid injury; | ||

Service | 1 year warranty with lifetime support (warranty does not include consumable parts). | ||

Equipment structure diagram:

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

Open type high flux four-channel tube furnace

Solid state battery pressure insulation mold set

3C vacuum pump

Three temperature zone 1700 ℃ tube furnace

Intelligent Chamber Furnace (27L) 1200°C

Microwave sintering furnace Microwave box type furnace

Press mold

Bridgman crystal growth furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China