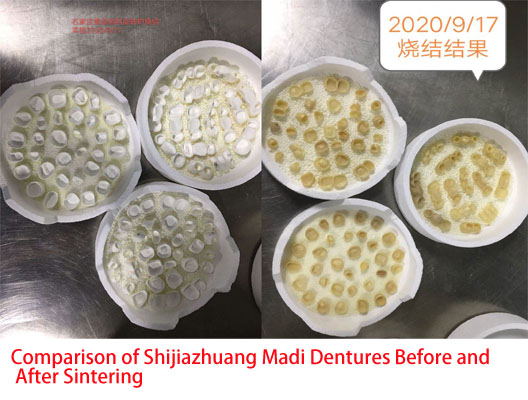

Bench denture crystal furnace

Release time: 2021-09-29 15:10:50 Number of views: 1349

Configuration details

| 1. Desktop design, easy to move and operate; | ||

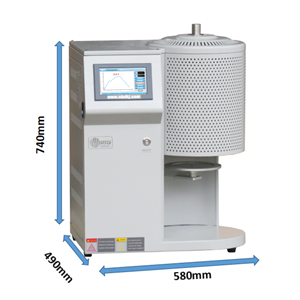

Model | NBD-B1600-12TI | ||

Specification | AC220V 2.5KW | ||

Tmax | 1550℃(<1 hour) | ||

load mode | bottom loading | ||

reachable heating rate | ≤20℃/min | ||

chamber size | Φ120*150mm | ||

control system |

| 1. Can prestore 15 denture sintering curves of various manufacturers, call at will. Each curve can be set 30 sections of "temperature-time" axis, to avoid the trouble caused by the repeated setting of different experimental processes; | |

Temperature accuracy | +/- 1℃ | ||

heating element |

|

| |

60KG | |||

Attention | If you want to sinter zirconium discs soaked with dye, be sure to dry them completely before placing them in the equipment for sintering to extend the service life of the equipment. | ||

Service support | 1 year warranty with lifetime support (The warranty does not include consumable parts, such as furnace tubes and sealing rings). | ||

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

NBD-LT cold and thermal fatigue testing machine

Industrial vertical sintering furnace

Ion sputtering device

1.5C vacuum pump

25 station vacuum atmosphere tube furnace

Extended sliding rail mobile fast annealing furnace

Press mold

0.45L melting furnace 1200℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China