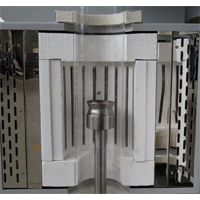

Vacuum vibrating vertical tube furnace

Release time: 2021-07-24 14:44:08 Number of views: 1395

Equipment introduction:

Vertical vacuum atmosphere vibrating sintering furnace adopts the structure design of vertical placement of furnace tube and annular distribution of furnace heating wire, which can be applied to the atmosphere sintering of a small amount of powder and granular samples. The equipment can operate in atmosphere or vacuum. The equipment adopts vibration mode to make the sample move regularly in the crucible, which makes the sample react more fully with the atmosphere when heated.

| 1. The heating wire is annular distributed inside the furnace, which encircle the furnace tube 360 degrees to improve the temperature uniformity in the furnace; | ||

Model | NBD-LT1200-100TI | ||

Electrical Spec | AC220V 2KW | ||

Tmax | 1200 ℃ | ||

Max working temps. | 1150 ℃ | ||

Heating rate | ≤20℃/min | ||

Effective working size | Φ150*200mm | ||

Tube size | Φ100*700mm | ||

Sample vessel | Nickel - based multi - hole plate, 50 micron, 10 micron interchangeable | ||

Control system |

| 1.NBD-101E embedded operating system English and Chinese interchange graphical interface, 7 inch real color touch screen input, intelligent man-machine dialogue mode; | |

Temp Accuracy | +/- 1 ℃ | ||

Heating element |

| Resistance wire, ring heating, more uniform temperature, sample sintering effect is better. | |

SEALING SYSTEM |

|

| 1. Stainless steel flange; |

Vacuum degree: ≤ 10Pa (mechanical pump), if higher vacuum is required, our molecular pump unit can be used | |||

Pressure measurement and monitoring |

| | |

Vacuum vibrator chamber |

| Torque resonant spring, stainless steel sealed cavity | |

Equipment usage precautions | When using the equipment, the pressure inside the furnace tube should not exceed 0.125MPa (absolute pressure) to prevent equipment damage caused by excessive pressure; | ||

Service Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and sealing rings) | ||

推荐产品

Rf independent system

Roll to roll two-dimensional material preparation system

High temperature elastic modulus tester heating system

vacuum braze furnace

Extended tube furnace with single temperature zone 1500℃

Intelligent Chamber Furnace (27L) 1200°C

Anaerobic well type sintering furnace (glove box + well type furnace)

2 station glove box

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China