Configuration details (glove box + series products)

| Equipment characteristics: 1. Simple: user-friendly design operation window,

2. Intelligent HMI man-machine interface, easy to operate;

3. Safety: high sealing fully protects the safety of human body and samples;

4. High efficiency: integrated design improves equipment use efficiency; Energy saving: frequency conversion control operation.

5. Heating, pressure and other heat treatment equipment can be modified according to customer requirements. |

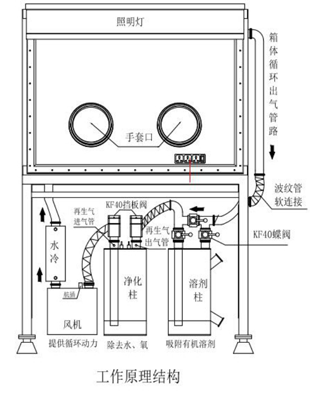

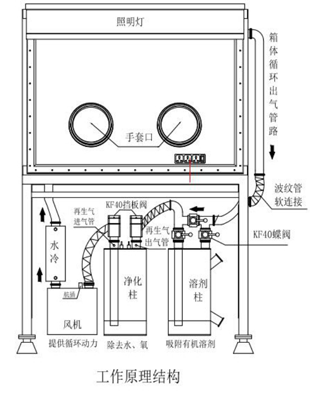

| Major component

1. Main box

2. Purification system

3. Solvent system

4. Water cooling

5. Large transition cabin

6. Small transition cabin

7. Control system

|

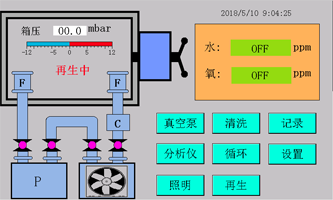

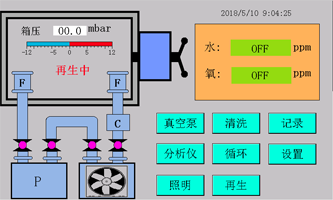

| Control system

1. Cycle cycle: start and stop cycle purification system;

2. True empty pump: start and stop vacuum pump;

3 lighting: open, take care of the lamp;

4. Analyzer: control water oxygen analyzer;

5. Cleaning: Set details of cleaning parameters;

6. Tacit value: restore the default value set by the system;

7. Alarm setting: set water oxygen alarm prompt;

8. Settings: alarm Settings and leak detection Settings of the box, switch between Chinese and English;

9. Regeneration: press the regeneration key to control the purification column for regeneration;

10. Time setting: preset touch screen display time;

11. Record: query system operation record and water oxygen content record;

|

| Transition cabin construction

1. Support frame; 2. Support rod; 3. Large hatch cover; 4. Large cabin shaft;

5. Large transition beam; 6. Handle; 7. Lead screw 8. Hook;

9. Vacuum pressure gauge;

10. Small hatch door;

11. Small hatch handle

12. Three-way ball valve;

|

| Replacement of activated carbon

① vacuum gauge; ② three-way ball valve; (3) feeding port; (4) discharge port;

Specific replacement process:

1. Close the two butterfly valves on the solvent column (butterfly valve ② and butterfly valve ③ in 10.2);

2. Check whether ① (vacuum gauge) is under normal pressure. If it is under vacuum state, supplement air to normal pressure through ② (three-way ball valve)

3. Open ③ (feeding port) and ④ (discharging port);

4. Activated carbon flows out from ④ (discharge port); Tighten the clamp after cleaning;

5. Pour clean and dry activated carbon from ③ (feeding port); After installation, tighten the clamp;

6. Through the operation of ② (three-way ball valve), vacuum the solvent column and replenish air for three times.

7. Repeat 5.11.2 to flow the circulating gas through the solvent column.

|

Electrical specification | AC220V 6KW*2 |

Preparation and inspection before use

| 1. Prepare sufficient high purity working gas (please refer to Table 1 for gas specifications)

2. Prepare two 40L cylinders of recycled gas (gas specifications refer to Table 2 below)

3. Second pair of decompression table (one is used normally, the other is used again)

use | Clean the box, balance the pressure and work gas | Gas type | Nitrogen, argon or helium | purity | 99.999% H2O ≤5ppm; O2 ≤5ppm or better | quantity | Meet the requirements of the equipment | Demand pressure | 0.4-0.6MPa | Pressure gauge range | Main surface pressure range >15MPa; Sub-surface pressure range ≤ 1MPa | Connecting pipe | Material: Plastic; External diameter: ¢10mm; Inside diameter: ¢6.5mm; | Table 1 High purity working gas |

use | Reduction purification column purification capacity | Gas type | When nitrogen is used as the working gas, nitrogen/hydrogen mixture (90-95% N2, 5-10% H2) is used;

When argon is used as the working gas, argon/hydrogen mixture (90-95% Ar, 5-10% H2) is used;

When helium is the working gas, use a helium/hydrogen mixture (90-95% He, 5-10%H2).

| purity | 99.999% H2O ≤5ppm; O2 ≤5ppm Or better | quantity | Each column requires 3500L or close to 40L cylinders of 10MPa gas pressure | Demand pressure | 约 0.01-0.03MPa | Pressure gauge range | Main surface pressure range >10MPa; Sub-surface pressure range < 0.5MPa | Connecting pipe | Material: Plastic; External diameter: ¢10mm; Inside diameter: ¢6.5mm; | Table 2 Regenerated gas |

|

Operation precautions | 1. Personnel shall not use the glove box without training;

2. Prohibit the use of materials that can poison the regeneration catalyst, such as: sulfhydryl compounds, etc.

3. Do not use volatile solvents that will damage plexiglass, such as acetone, without permission;

4. Before using volatile solvent, contact the person in charge to unload the water probe;

5. Open the activated carbon circulation system when using volatile solvent;

6. When using the glove box, do not have long nails, do not wear sharp objects (such as watches, jewelry, etc.);

|

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.