Anaerobic well type sintering furnace (glove box + well type furnace)

Release time: 2021-04-28 11:41:42 Number of views: 1243

Equipment introduction:

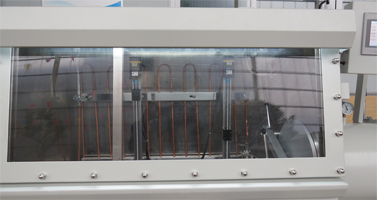

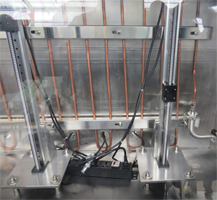

The glove box is equipped with a crucible furnace to perfectly achieve sample sintering under vacuum or atmosphere, and is equipped with an electric lifting and pulling system to achieve rapid sample rising and cooling, convenient sampling, heating elements evenly arranged around the furnace chamber, and high temperature field uniformity. It is suitable for high temperature sintering, melting and heat treatment of metal, non-metal, alloy, ceramic and other materials in scientific research institutes, university laboratories and industrial and mining enterprises.

Configuration

| Equipment features:

| |

Control system |

1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely;

| |

heating furnace | 2 sets of heating furnaces (divided into left and right chambers, can be heated separately or simultaneously) | |

Chamber size | Φ150*200mm | |

Pressure measurement & monitoring | Mechanical pressure gauge with damping oil prevents gauge pointer from being damaged (digital vacuum gauge is optional) | |

vacuum system | Vacuum degree: ≤5Pa (mechanical pump) | |

measuring range | RT—1100℃ | |

Heating rate | 30℃/min, Recommended heating rate ≤ 10℃/min | |

cooling system |

| |

Crucible material | 310S | |

Sample measuring environment | Air environment; Static, dynamic atmosphere environment; Or vacuum environment (≦1000℃) | |

operational process

| First, vacuum is pumped, gas displacement is carried out through the atmosphere, and then the sample is sent from the transition bin to the glove box chamber, the sample is fixed on the electric lifting motor, sent into the crucible for processing, and then lifted into the glove box for rapid cooling by air cooling. | |

Cautions | 1. The internal pressure of the gas supply cylinder is high, and when the gas is passed into the glove box, the pressure reducing valve must be installed on the cylinder. It is recommended to choose a small pressure reducing valve for testing, and the measuring range of the pressure reducing valve is 0.01 MPA-0.15 MPa, which will be more accurate and safe in use.

| |

standard configuration | 1. One single-station glove box;

| |

Service | 1 year warranty, lifetime service (warranty does not include consumable parts). | |

Net weight | 400KG | |

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

CVDO1200-XT33G2F

Vertical quenching furnace

well-type crucible melting furnace 0.1L 1200℃

Anaerobic hot dip plating (quenching) system

1200°C Mixing Chamber/Tube Furnace

Rotary pendulum oxidation furnace (silicon nitride tube)

Anti-corrosion mini chamber furnace

PECVD plasma chemical vapor deposition system

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China