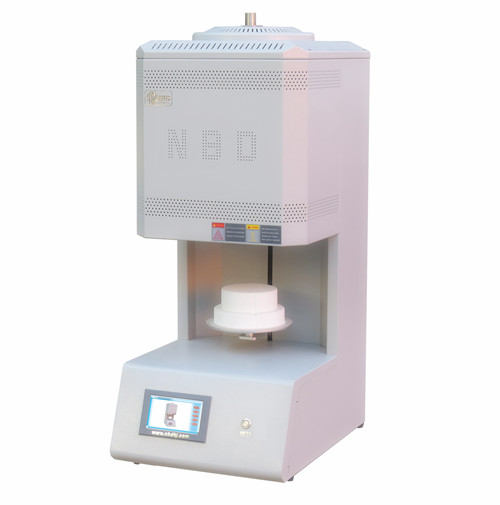

1200 ℃ CVD integrated machine

Release time: 2021-04-20 13:06:49 Number of views: 1386

The NBD-CVD1200 series all-in-one machine adopts international advanced manufacturing technology and is designed from an aesthetic and artistic perspective based on human safety. The control system adopts advanced PLC+touch screen control system, making operation simpler and more convenient. The temperature control adopts advanced PID fuzzy control to maintain the temperature control accuracy within±1℃. Suitable for conducting high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, vacuum annealing, and other experiments in universities, research institutes, and industrial and mining enterprises.

| 1. The integration of the furnace body and control system makes the experiment convenient, fast, and intuitive.

| ||||||||||||

PRODUCT MODEL | NBD-CVDO1200 | ||||||||||||

Furnace tube diameter | Φ50、φ60、φ80、φ100 (Optional) | ||||||||||||

operation temperature | ≤1100℃ | ||||||||||||

Temperature zone selection | Single temperature zone | Dual temperature zone | Three temperature zones | ||||||||||

Heating zone size | 440mm | 200mm + 200mm | 200mm + 400mm + 200mm | ||||||||||

Electrical specifications | AC220V 4KW | AC220V 5KW | AC220V 8KW | ||||||||||

heating rate | suggestion10℃/min | ||||||||||||

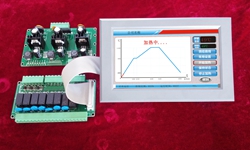

control system |

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; | ||||||||||||

Gas system (optional) | Flow meter type | rotameter | Mass flowmeter | ||||||||||

Pipeline schematic diagram |

|

| |||||||||||

Number of intake ports | 2. 3, 4 (multiple options available) | ||||||||||||

Flow range | 20-250/20-800ml/min(Multiple range options) | 50/100/200sccmMultiple range options) | |||||||||||

Range of working pressure difference | 0-0.15MPa | ||||||||||||

Low vacuum system (optional) | Vacuum pump model | NBD-1.5C | NBD-3C | NBD-4C | |||||||||

Pumping speed | 1L/s | 3L/s | 4L/s | ||||||||||

Inlet and exhaust port size | Φ8mmPagoda joint | Φ8mmPagoda joint | KF16/25 | ||||||||||

limiting pressure | 1000Pa | 100Pa | 10Pa | ||||||||||

operation temperature | 5-40℃ | ||||||||||||

Electrical specifications | AC220V | ||||||||||||

High vacuum system (optional) | Vacuum pump model | NBD-103(A) | NBD-103(B) | NBD-103(C) | |||||||||

pumping speed | 110L/s | 600L/s | 700L/s | ||||||||||

Vacuum gauge | Composite vacuum gauge | ||||||||||||

limiting pressure | 10^-3Pa | 10^-4Pa | 10^-5Pa | ||||||||||

operation temperature | 5-40℃ | ||||||||||||

Electrical specifications | AC 220V | AC 220V | AC 380V | ||||||||||

* Support non-standard customization. For more models, please call 400-000-3746 for inquiries | |||||||||||||

推荐产品

Cold wall rapid annealing furnace

1500℃ intelligent muffle furnace

Two float proportioners

Horizontal silent ball mill mixer

Large capacity bottom-loading furnace

Touch screen mass flow control distribution cabinet

Oscillating ball mill mixer

Vacuum storage cabinet

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China