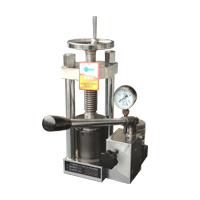

Manual tablet press(8T)

Release time: 2021-04-15 13:47:19 Number of views: 1299

Configuration

| 1. Pressure stability: special oil circuit design;

| ||||||||||||

Model | SYP-8T | ||||||||||||

pressure range | 0~8T | ||||||||||||

piston diameter | 70mm (platform diameter 90mm) | ||||||||||||

travel of piston | 0-20mm | ||||||||||||

work space | Φ95*120mm | ||||||||||||

boundary dimension | L190mm H420mm D220mm (without handle) | ||||||||||||

Pressure stability | ≤0.5MPa/5min | ||||||||||||

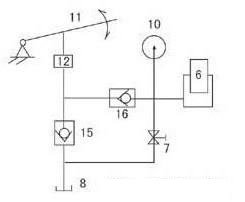

Oil circuit principle |

| When working, the oil drain valve 7 is closed. Swing the manual pressure lever 11, the oil from the oil pool 8 through the check valve 15 suction, through the oil outlet valve 16 pressure into the large piston 6, so that the continuous energy, and the formation of high pressure oil, and displayed in the pressure gauge 10, when the oil release valve 7, you can be unloaded.

| |||||||||||

Net weight | 19KG | ||||||||||||

Cylinder pressure conversion | Cylinder pressure =0.4T/Mpa* Gauge MPA index

| ||||||||||||

Cautions |

1. When using the tablet press, the maximum working pressure limit of the mold must be observed. Exceeding the working limit pressure will lead to mold damage. The maximum working pressure of molds with different diameters is different (the maximum working pressure is marked on the mold box label).

| ||||||||||||

Tablet machine use precautions | 1. To remove air from the system. (If not used for a long time, it is recommended to tighten the pressure relief valve to prevent air entry)

| ||||||||||||

Service | One year warranty with lifetime support (warranty does not include consumable parts) | ||||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|

|

|

|

|

|

推荐产品

12L intelligent box furnace

Roll to roll two-dimensional material preparation system

Openable vertical tube furnace 1200℃

Spiral heater

Lift type large capacity sintering furnace

0.2L melting furnace 1200℃

Multichannel gas automatic controller

Heat resistant material test furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China