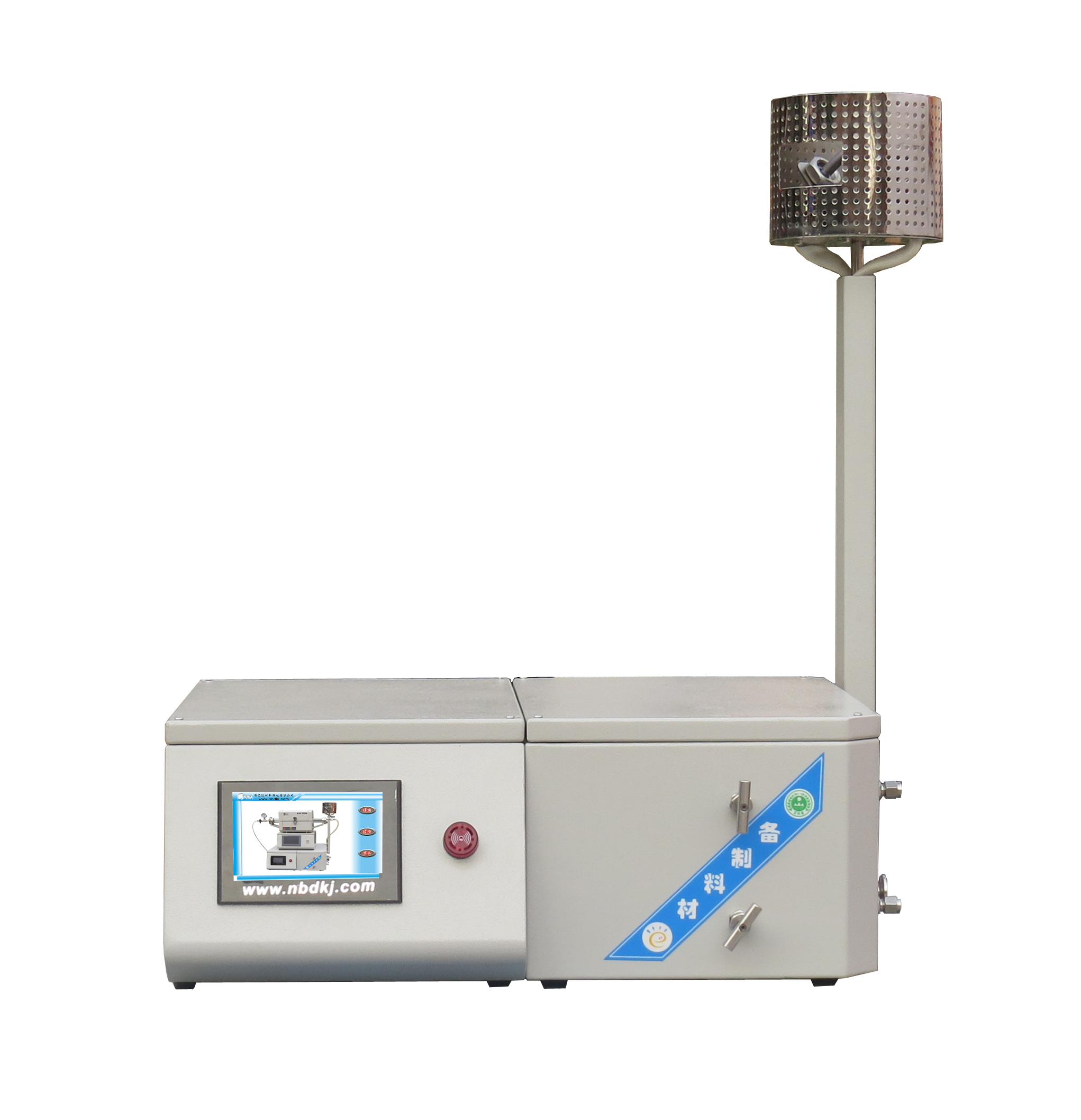

Chemical vapor deposition CVD all-in-one machine

Release time: 2021-04-14 10:17:11 Number of views: 1631

Equipment Introduction:

Chemical vapor deposition (CVD) refers to the method of synthesizing coatings or nanomaterials by reacting chemical gases or vapors on the surface of a substrate. It is the most widely used technique in the semiconductor industry for depositing thin film materials, including a wide range of insulating materials, as well as most metal materials and metal alloy materials. We have developed a complete CVD coating system for this purpose, which is suitable for material laboratories, research institutes, environmental science and other fields in major universities;

|

设备特点 Equipment features | |||||||||

PRODUCT MODEL | NBD-T1700-80TIG3Z | |||||||||

operation temperature | ≤1650℃ | |||||||||

Heating zone size | 310mm | |||||||||

| Size of constant temperature zone | 220mm | |||||||||

heating rate | ≤20℃/min | |||||||||

Electrical specifications | AC220 4.5KW | |||||||||

| control system |   | 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; | ||||||||

Gas system (optional) | Flow meter type | rotameter | Mass flowmeter | |||||||

Pipeline schematic diagram |

|

| ||||||||

Number of intake ports | 2. 3, 4 (multiple options available) | |||||||||

Flow range | 20-200/60-600l/min (multi range optional) | 50/100/200sccm (multi range optional) | ||||||||

Range of working pressure difference | 0-0.15MPa | |||||||||

Low vacuum system (optional) | Vacuum pump model | NBD-1.5C | NBD-3C | NBD-4C | ||||||

pumping speed | 1L/s | 3L/s | 4L/s | |||||||

Inlet and exhaust port size | Φ8mmPagoda joint | Φ8mmPagoda joint | KF16/25 | |||||||

limiting pressure | 1000Pa | 100Pa | 10Pa | |||||||

operation temperature | 5-40℃ | |||||||||

Electrical specifications | AC220V | |||||||||

Molecular pump high vacuum system

| Molecular pump system model | NBD-103(A) | NBD-103(B) | NBD-103(C) | ||||||

pumping speed | 110L/s | 600L/s | 700L/s | |||||||

Vacuum gauge | Composite vacuum gauge | |||||||||

limiting pressure | 10^-3Pa | 10^-4Pa | 10^-5Pa | |||||||

operation temperature | 5-40℃ | |||||||||

Electrical specifications | AC 220V | AC 220V | AC 380V | |||||||

*Support non-standard customization. For more models, please call 400-000-3746 for inquiries | ||||||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

推荐产品

Epitaxial furnace exhaust gas purifier

3-way mass gas proportioner

System O1200-XT22D2F

Extended tube furnace with single temperature zone 1500℃

Anaerobic purification electrolytic furnace

medium frequency induction melting furnace

0.35L melting furnace 1600℃

Gas safety protection device for tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China